- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

STA

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Henan, China

-

Model Number:

-

STA-LED-002

-

Brand Name:

-

STA

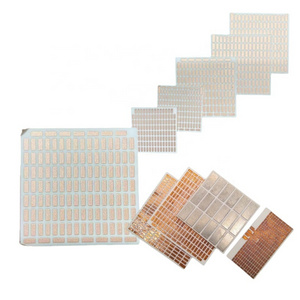

STA high quality Metallized 96% alumina ceramic substrate for LED

the introduction

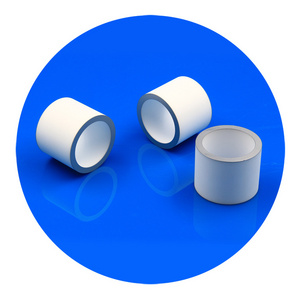

Our proprietary alumina formulation produces a fine-grain substrate with excellent surface finish and dielectric characteristics. Our substrate is ideal for thin-film applications with ultra fine-line resolution and spacing. Our current capability is producing substrates as large as 15"x 15". We are currently expanding our production capacity to make 36"x 36" substrates. Once we complete the expansion our substrates will be one of the largest manufactured substrates available.

a lu mina substate

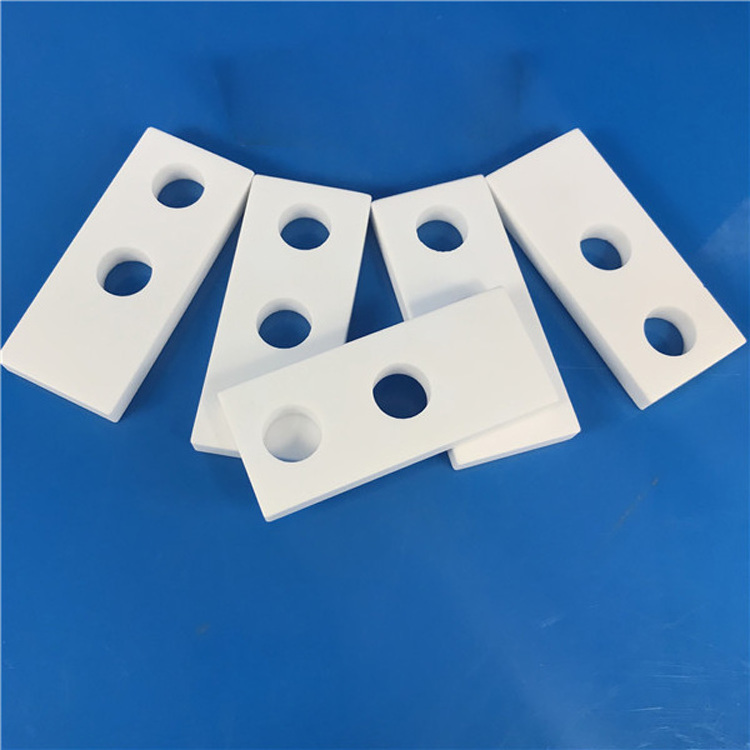

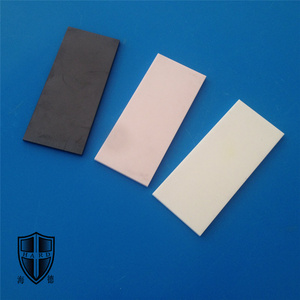

1. material:96 / 99 ALUMINA CERAMIC, zirconia ceramic etc.

2. method of moulding: thermal casting/drying press/extrusion

3. colour: white/light yellow

4. sintering temperature: 1580c

5. surface finish:Ra0.4 &SIM RA 0.8&mum etc, upon your requirement.

6. package: packing with carton and ship with wooden box.

7. we can produce them by your molds or te drawings you require.

Features

1.Good chemical capability and insulation

2.Good performance and long-term life

3.Support laser/mold production

4.Good Electrical Insulation,Wear & Corrosion Resistant

Regular thickness

0.25mm 0.28mm 0.45mm 0.5mm 0.635mm 1.0mm 1.5mm 1.8mm 2.0mm

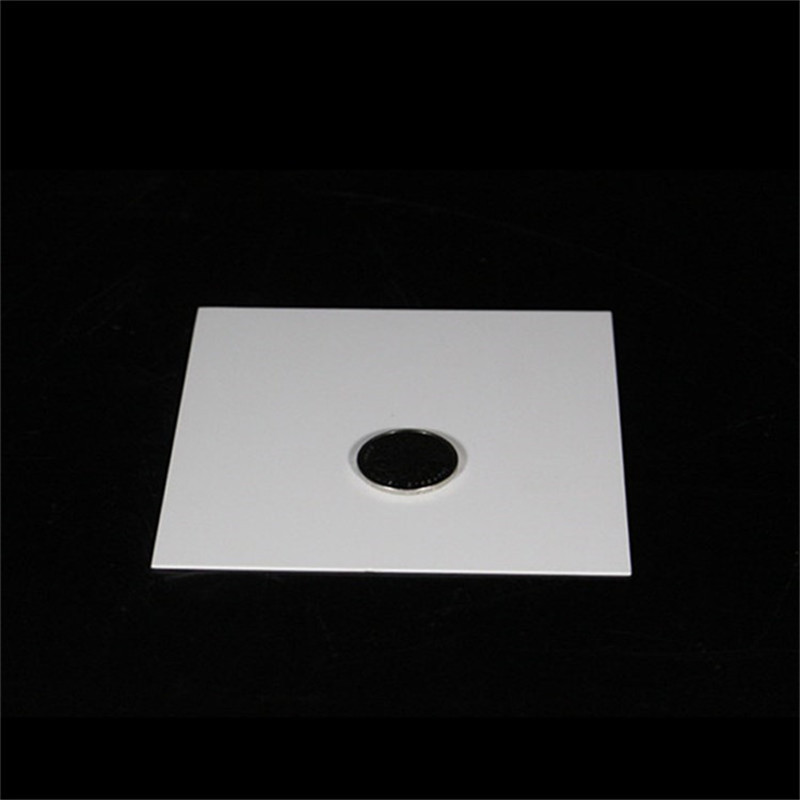

Metallized

The surface can be covered a lay of metallization,such as Ag, Pd-Ag,Mo-Mn, Ni-plating with good tensile strength: Mo-Mn thickness: 25~40μm,Ni thickness:3~7μm, Tensile strength≥120MPa

the technical date of the alumina substrate

|

Item |

Test Condition |

Unit&Symbol |

95%Alumina ceramics |

99%Alumina ceramics |

99.6%Alumina ceramics |

|

The main chemical ingredient |

|

|

Al2O3 |

Al2O3 |

Al2O3 |

|

Bulk Density |

|

g/cm3 |

3.6 |

3.89 |

3.96 |

|

Maximum Use Temperature |

|

|

1450°C |

1600°C |

1650°C |

|

Water absorption |

|

% |

0 |

0 |

0 |

|

ROHS Hardness |

|

|

≥85 |

≥89 |

≥89 |

|

Flexural strength |

20° C |

MPa (psi x 103) |

358 (52) |

550 |

550 |

|

Compressive Strength |

20° C |

MPa (psi x 103) |

2068 (300) |

2600(377) |

2600(377) |

|

Fracture Toughness |

K(I c) |

Mpa m1/2 |

4-5 |

5.6 |

6 |

|

Coefficient of thermal expansion |

25-1000° C |

1X 10-6/°C |

7.6 |

7.9 |

8.2 |

|

Coefficient of thermal conductivity |

20° C |

W/m °K |

16 |

30.0 |

30.4 |

|

Thermal Shock Resistance |

Tc |

°C |

250 |

200 |

200 |

|

Dielectricity constant |

1MHz.25°C |

|

9 |

9.7 |

9.7 |

|

Dielectric strength |

|

ac-kV/mm (ac V/mil) |

8.3 (210) |

8.7 (220) |

8.7 (220) |

|

Volume Resistivity |

100°C |

ohm-cm |

> 1013 |

> 1014 |

> 1014 |

Application:

Widely used in ceramic package, electronic substrate, LED heat dissipation substrate, etc.