- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380v

-

Power:

-

6300

-

Dimension(L*W*H):

-

570*130*175mm

-

Weight (KG):

-

5.9

-

Core Components:

-

burner

-

Working Gas:

-

Natural Gas,LPG

-

Working Gas Presuure:

-

3000 to 5000 Pascal

-

Heating Type:

-

Infrared Radiant

-

Material:

-

Cast Iron and Ceramic

-

Fits for:

-

Oven temperature requirement less than 500 degree

-

Weight:

-

8kg

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

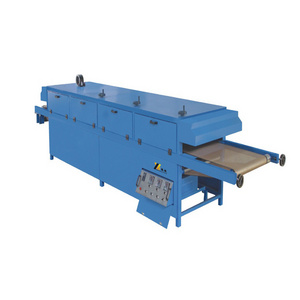

Quick Details

-

Type:

-

Drying Oven

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

THD

-

Voltage:

-

220v/380v

-

Power:

-

6300

-

Dimension(L*W*H):

-

570*130*175mm

-

Weight (KG):

-

5.9

-

Core Components:

-

burner

-

Working Gas:

-

Natural Gas,LPG

-

Working Gas Presuure:

-

3000 to 5000 Pascal

-

Heating Type:

-

Infrared Radiant

-

Material:

-

Cast Iron and Ceramic

-

Fits for:

-

Oven temperature requirement less than 500 degree

-

Weight:

-

8kg

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

Products Description

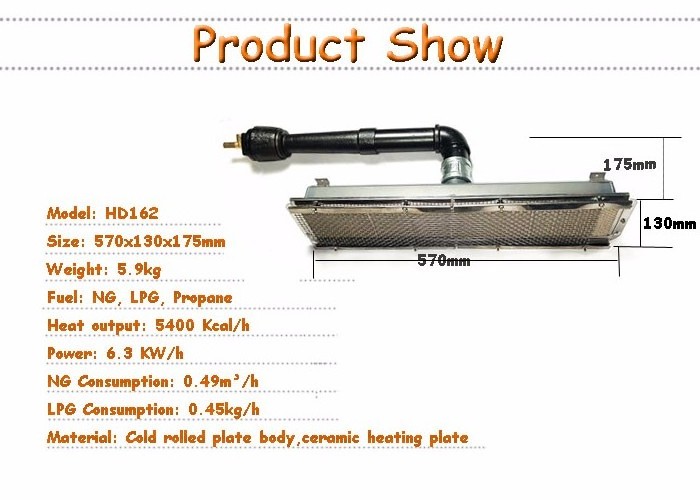

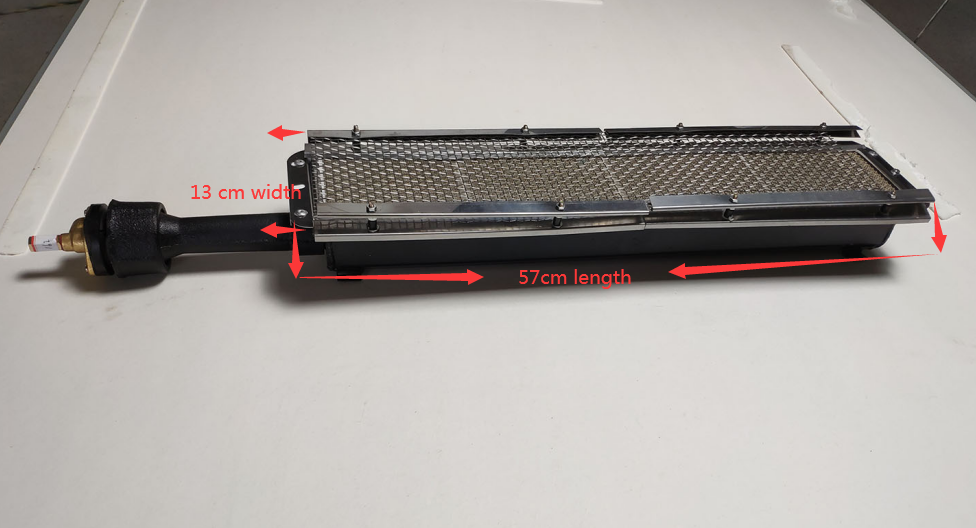

Infrared Ceramic Catalytic Gas,LPG Industrial Burner,Heater for Industrial Oven HD162

Haodong Infrared Burner covers a process rare earth as catalyst, make the flameless

burning occurred at the ceramic surface and radiate directly. So, the energy transfer rate is much higher than common ceramic burner.

Gas Infrared Burner Technical Parameters

|

SN

|

Items

|

Technical Parameters

|

|

1

|

Kinds of Gas

|

NG/LPG/Oil Field Gas/Artificial Gas

|

|

2

|

Perfect Combustion Temperature

|

≤380℃

|

|

3

|

Heat Source Temperature

|

850℃

|

|

4

|

Heating-up Temperature Range

|

35℃-500℃

|

|

5

|

Wavelength Range

|

4 um -15 um

|

|

6

|

Working Pressure

|

2000pa(NG)~5000pa

2800pa(LPG)~~5000pa

|

|

7

|

Life Span

|

Above 11000hrs

|

|

8

|

Waste Gas Emission

|

CO≤80ppm;NOx≤10ppm;CHx≤50ppm

|

|

9

|

Conversion Rate

|

Above 90%

|

Gas

Industrial

Infrared

Burner,Heater

Main

Material:

1. Shell Body: Cast Iron,Galvanized Sheet

2. Air blast pipe: Cast Iron

3. Radiant Part: Rare earth ceramic heating part

4. Nozzle: Brass

5. Up cover: Stamped stainless iron

2. Air blast pipe: Cast Iron

3. Radiant Part: Rare earth ceramic heating part

4. Nozzle: Brass

5. Up cover: Stamped stainless iron

Gas

Industrial

Infrared Burner,Heater

Main

Specification:

|

Model

|

Outer Dimension

|

Weight

|

Gas Type

|

Heat Output

|

|

Consumption

|

|

||

|

|

mm

|

kg

|

|

KW/h

|

Kcal/hr

|

NG(m3/h)

|

LPG(kg/h)

|

||

|

HD61

|

423*80*94

|

3.8

|

NG/LPG

|

2.4

|

2030

|

0.18

|

0.17

|

||

|

HD81

|

555*80*115

|

5.8

|

NG/LPG

|

3.1

|

2700

|

0.24

|

0.22

|

||

|

HD82

|

219*164*108

|

4.8

|

NG/LPG

|

3.1

|

2700

|

0.24

|

0.22

|

||

|

HD101

|

690*80*115

|

6.9

|

NG/LPG

|

3.9

|

3380

|

0.3

|

0.28

|

||

|

HD162

|

570*130*175

|

5.9

|

NG/LPG

|

6.3

|

5400

|

0.49

|

0.45

|

||

|

HD410

|

410*175*220

|

8.1

|

NG/LPG

|

6.3

|

5400

|

0.49

|

0.45

|

||

|

HD242

|

840*130*175

|

7.3

|

NG/LPG

|

9.4

|

8120

|

0.75

|

0.68

|

||

|

HD600

|

600*175*220

|

10.5

|

NG/LPG

|

9.4

|

8120

|

0.75

|

0.68

|

||

|

HD262

|

930*130*175

|

7.8

|

NG/LPG

|

10.9

|

9360

|

0.8

|

0.74

|

||

Details Images

Related Products:

Our Advantages

1.High energy transfer rate:above 95%,other gas burner only 75%-80%

2.High Efficiency:start work in 8 seconds

3.Individual operation:Each burner has individual ignition control system,some problem will not affect other burner’s working

4.IR heating directly : heat direct by Radiant Infrared Ray,no need combusion chamber ,blower

5.Environment protecting: Low pollution

2.High Efficiency:start work in 8 seconds

3.Individual operation:Each burner has individual ignition control system,some problem will not affect other burner’s working

4.IR heating directly : heat direct by Radiant Infrared Ray,no need combusion chamber ,blower

5.Environment protecting: Low pollution

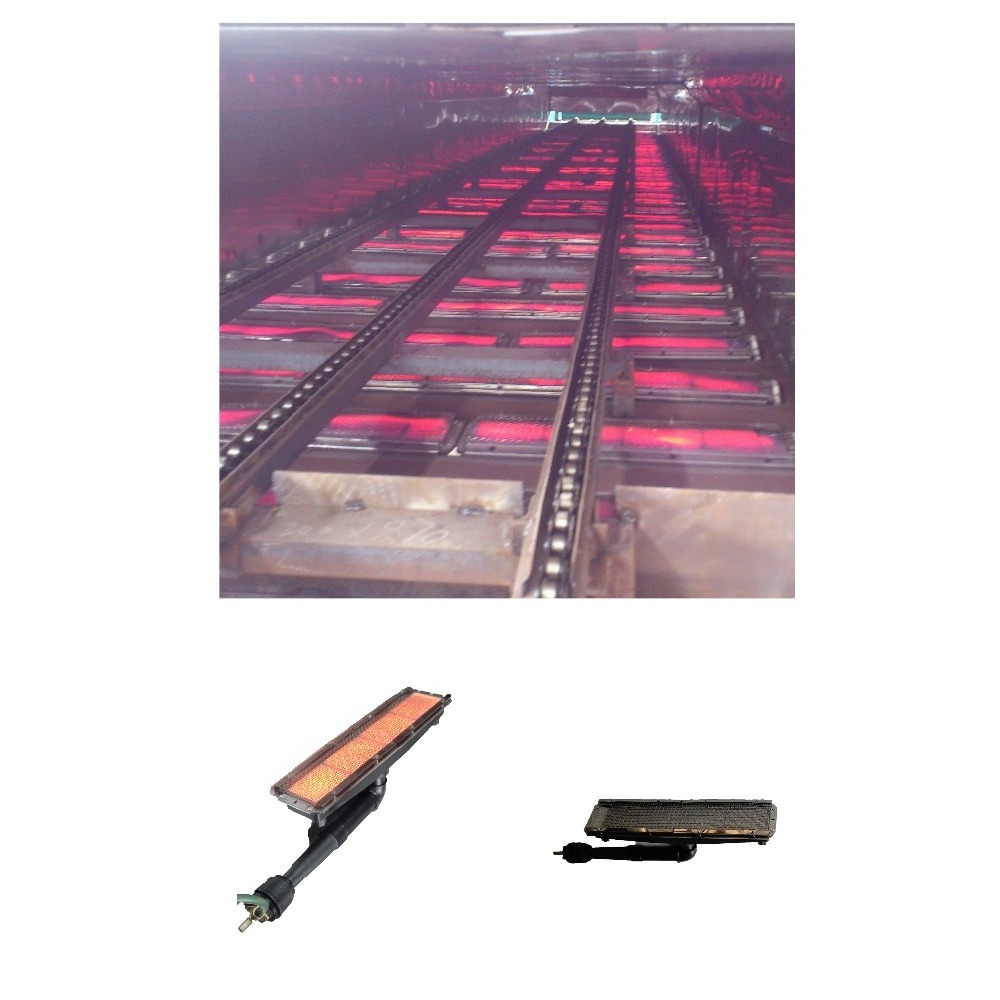

Appliation

This infrared gas burner fits for:

Drying oven

- animal foods, cereal and vegetable crops.

Curing oven - dry powder and wet paint coating applications, including stove enamelling and vitreous enamel

Plastic shrink wrapping.

Heat walls - for textile, carpet and paper drying.

Heat treatment ovens.

Forced draught installations - fabrication,pre-heating.

Foundry mould and core drying.

Die heating.

Ceramic holloware and flatware - prior/post glazing.

Metal billet heating.

Metal annealing.

Rubber&plastic forming ,glass anneal process,nonwoven fiber drying.

Curing oven - dry powder and wet paint coating applications, including stove enamelling and vitreous enamel

Plastic shrink wrapping.

Heat walls - for textile, carpet and paper drying.

Heat treatment ovens.

Forced draught installations - fabrication,pre-heating.

Foundry mould and core drying.

Die heating.

Ceramic holloware and flatware - prior/post glazing.

Metal billet heating.

Metal annealing.

Rubber&plastic forming ,glass anneal process,nonwoven fiber drying.

More products

Hot Searches