- Product Details

- {{item.text}}

Quick Details

-

Type:

-

clean grain

-

Use:

-

clean grain

-

Production Capacity (kg/h):

-

100000 - 300000

-

Sieve Size(mm):

-

custom

-

Power (kW):

-

custom

-

Weight:

-

10 KG

-

Feature:

-

adjustable angle with doble barrel

-

Function:

-

Grain Size Separation

-

Capacity:

-

3 T/h-300T/H

-

Voltage:

-

220V/380V/customized

-

Auxiliary Seed Conveying System:

-

Conveyor

-

Dust Removal System:

-

Dust Collector

-

Advantage:

-

Higher Efficiency

-

Grain Processing Screen Size:

-

100x200 Cm or customized

-

MOQ:

-

1 Set

-

Kw:

-

2.2-7.5

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TSE

-

Dimension(L*W*H):

-

custom

-

Type:

-

clean grain

-

Use:

-

clean grain

-

Production Capacity (kg/h):

-

100000 - 300000

-

Sieve Size(mm):

-

custom

-

Power (kW):

-

custom

-

Weight:

-

10 KG

-

Feature:

-

adjustable angle with doble barrel

-

Function:

-

Grain Size Separation

-

Capacity:

-

3 T/h-300T/H

-

Voltage:

-

220V/380V/customized

-

Auxiliary Seed Conveying System:

-

Conveyor

-

Dust Removal System:

-

Dust Collector

-

Advantage:

-

Higher Efficiency

-

Grain Processing Screen Size:

-

100x200 Cm or customized

-

MOQ:

-

1 Set

-

Kw:

-

2.2-7.5

Grain cleaning machine (also called Grain Pre Cleaner)

is the important grain cleaners, it is designed and manufactured by Shelley Engineering for simple, fast removal of light and heavy (rubble) impurities from grain, corn, soybeans, wheat, rice or fuel whose particles sizes and weighs are different than impurity particle, all the grain and the impunity dust are inputed into the rotating screen cylinder,The inner mesh and the out mesh have different diameters, the grains are isolated and flow out through different

exit from the dusts in the continuous screening process. The grain cleaner can also be used for screening soybean meal, soybean meal blocking the bulk through continuous rotation, making the soybean meal block decreasing in monocular state.This kind of grain cleaning equipment reduces the emission of dust into the atmosphere.

exit from the dusts in the continuous screening process. The grain cleaner can also be used for screening soybean meal, soybean meal blocking the bulk through continuous rotation, making the soybean meal block decreasing in monocular state.This kind of grain cleaning equipment reduces the emission of dust into the atmosphere.

When the TCQY series cylinder primary cleaning screen is working, the grain that needs to be cleaned flows from the feed port into the inner screen of the double straight cylindrical screen. Through the rotation of the screen and the material level difference, the material flows in the screen for continuous screening. Therefore, grain and impurities smaller than the sieve hole of the inner sieve tube fall into the outer sieve tube through the sieve holes, while the large impurities larger than the sieve hole of the inner sieve tube stay in the inner sieve tube and flow to the large impurities outlet, which is smaller than the outer sieve tube sieve. The small impurities in the holes flow into the small hopper through the sieve holes, and the grain left in the outer sieve cylinder is pushed forward and falls into the grain output hopper through the rotation of the sieve cylinder and the material level difference; the dust is sucked out through the air duct.

Specification

|

Model parameter

|

|

TQLY

100/220 |

TQLY

100/320 |

TQLY

100/320-4B |

TQLY

100/420 |

TQLY

125/420 |

TQLY

125/520 |

|

|

Produce quantity

T/H

|

corn

|

30-50

|

40-80

|

120-180

|

60-100

|

75-130

|

85-150

|

|

|

|

wheat

|

35-55

|

50-90

|

120-160

|

70-100

|

80-120

|

80-140

|

|

|

|

Soybeans

|

40-55

|

45-90

|

120-200

|

65-100

|

80-150

|

80-165

|

|

|

|

Rice

|

20-30

|

30-40

|

70-90

|

45-80

|

55-90

|

65-110

|

|

|

National Tsing Hua University miscellaneous rate(%)

|

|

80

|

80

|

80

|

80

|

80

|

80

|

|

|

Cleanup rate(%)

|

|

40

|

40

|

40

|

40

|

40

|

40

|

|

|

Power(Kw)

|

|

2.2

|

4

|

2×4

|

5.5

|

7.5

|

7.5

|

|

|

Air volume(m3/h)

|

|

3000

|

4000

|

7500

|

5500

|

6000

|

7000

|

|

Features of

Grain Cleaning Machine

* Suitable to remove light dust or chaff.

* Fan can be situated to cyclone with negative pressure to minimize dust leaks when exhaust ducting.

* Equipped with 4 fitted mounting brackets.

* Fully galvanized construction for outdoor use.

* Triple extraction point for 3 times the performance.

* Fully adjustable internal guides to ensure the best performance on every crop.

* Side viewing panels to see the adjustment effects.

* Fan can be situated to cyclone with negative pressure to minimize dust leaks when exhaust ducting.

* Equipped with 4 fitted mounting brackets.

* Fully galvanized construction for outdoor use.

* Triple extraction point for 3 times the performance.

* Fully adjustable internal guides to ensure the best performance on every crop.

* Side viewing panels to see the adjustment effects.

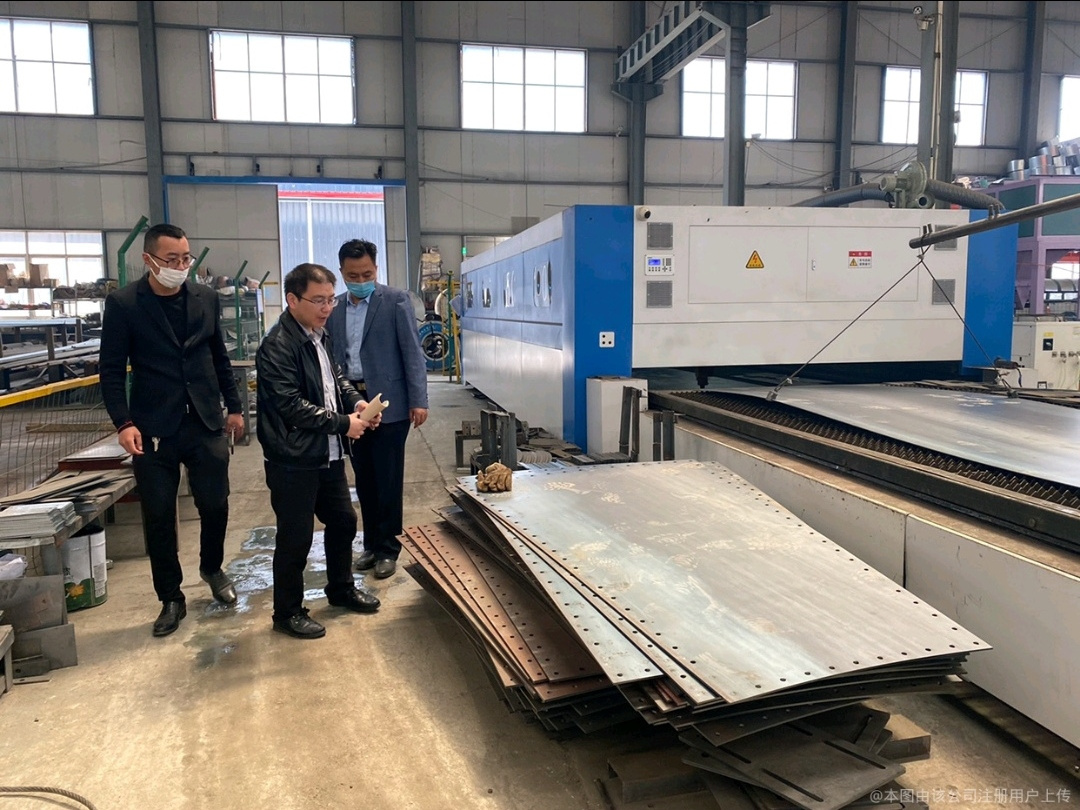

Our Company

Shelley Engineering

is the professional steel grain silos designer and manufacturer dedicated in supplying turn key grain storage and handling solutions to worldwide customers. We have more than 30 talented grain storage solutions experts and 9,000 square meters state-of-the-art factory. Our innovative, high-quality flat bottom silos, hopper bottom silos, powder silos, feed silos, bucket elevators, dust collectors and grain storage control system are integrated as a system to satisfy your grain storage requirements.

Shelley Engineering is not only manufacturing best quality grain storage products but also providing professional design and installation service. OEM, ODM, custom design and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.

Shelley Engineering is not only manufacturing best quality grain storage products but also providing professional design and installation service. OEM, ODM, custom design and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.

Our Factory

TSE Production Area

TSE Package Area

TSE Shipment

Our Client

Certifications

Hot Searches