- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MUSTANG

-

Voltage:

-

380V,3phase

-

Power:

-

3KW

-

Dimension(L*W*H):

-

1600*1200*1250 mm

-

Weight (KG):

-

480

-

Product name:

-

Horizontal Double Ends Mortising Machine for Wood Tenoning Machine

-

Keyword:

-

Double Ends Mortising Machine

-

After-sales Service Provided:

-

Online Support

-

Type:

-

Working Mortiser

-

Usage:

-

Mortising Tenon Hople

-

Processing material:

-

Wood

-

Spindle speed:

-

12000R/MIN

-

Max groove width:

-

130mm

-

Max groove depth:

-

60mm

-

Motor power:

-

3KW

Quick Details

-

Application:

-

Furniture Woodworking

-

Motor Speed:

-

12000r/min

-

Drill Diameter:

-

5-35mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MUSTANG

-

Voltage:

-

380V,3phase

-

Power:

-

3KW

-

Dimension(L*W*H):

-

1600*1200*1250 mm

-

Weight (KG):

-

480

-

Product name:

-

Horizontal Double Ends Mortising Machine for Wood Tenoning Machine

-

Keyword:

-

Double Ends Mortising Machine

-

After-sales Service Provided:

-

Online Support

-

Type:

-

Working Mortiser

-

Usage:

-

Mortising Tenon Hople

-

Processing material:

-

Wood

-

Spindle speed:

-

12000R/MIN

-

Max groove width:

-

130mm

-

Max groove depth:

-

60mm

-

Motor power:

-

3KW

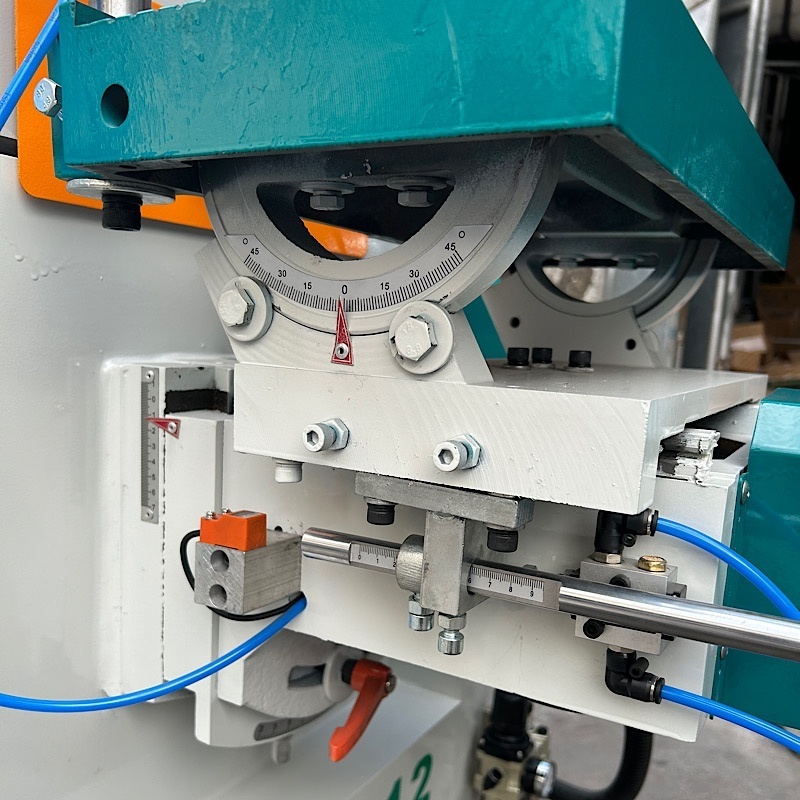

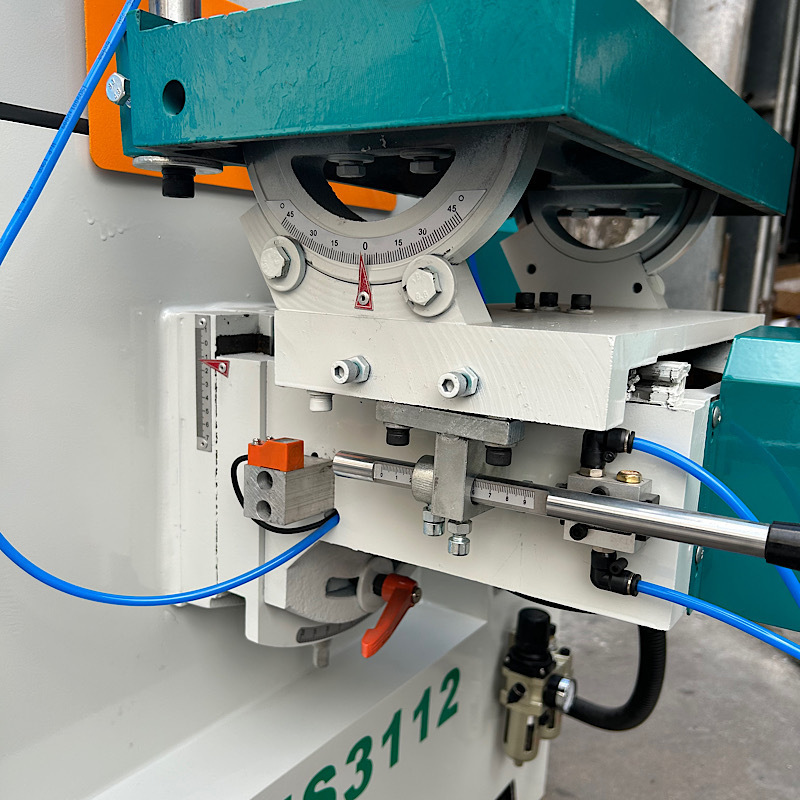

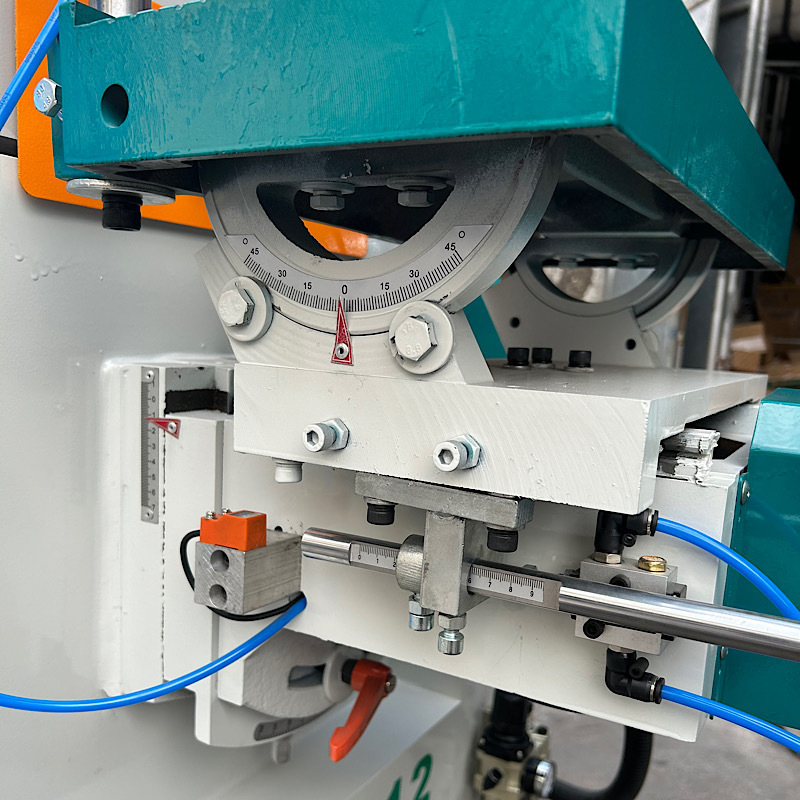

Mustang MS3112 Horizontal Double Ends Mortising Machine for Wood Tenoning Machine

Products Description

1. The machine suit for mortising of doors, tables or chairs. With adjustable working width through the digital display and 30 degree tiltable working table allowing angle mortising. Spindle assembly sliding along précising guide rail, insure processing quality and efficiency.

2. The machine adopted adjustable dual working table, tilting adjustable; processing on dual table at the same time, doubled efficiency.

3. Main spindle assembly fast moving along with precision guide rail, high accuracy and speed; suitable for heavy duty cutting.

4. Through digital display adjustment of mortising width of ,processing direct and accurate.

5. Unique spindle adjustment mechanism allowed left and right moving speed change of the main spindle to adapt with different requirements and insure working quality and efficiency.

2. The machine adopted adjustable dual working table, tilting adjustable; processing on dual table at the same time, doubled efficiency.

3. Main spindle assembly fast moving along with precision guide rail, high accuracy and speed; suitable for heavy duty cutting.

4. Through digital display adjustment of mortising width of ,processing direct and accurate.

5. Unique spindle adjustment mechanism allowed left and right moving speed change of the main spindle to adapt with different requirements and insure working quality and efficiency.

Product Paramenters

|

Model

|

MS3112

|

|

Max groove width

|

130mm

|

|

Max Groove deepth

|

60mm

|

|

Rated Current

|

4.7A

|

|

Working table lifter stroke

|

±80 mm

|

|

The tilted angle of working table

|

20°

|

|

Maximum tenon chamfer width

|

120+2R mm

|

|

Spindle speed

|

12000 r/min

|

|

Total power

|

3 KW

|

|

Air consumption

|

0.6Mpa

|

|

Net weight

|

480 kg

|

|

Overall dimensions

|

1600*1200*1250 mm

|

Details Images

Hot Searches