- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

tongjia

-

Model Number:

-

TJSM-01

-

Dimension(L*W*H):

-

37600x1000x2300mm

-

Weight:

-

20 TONS

-

Power:

-

Depend

-

Certification:

-

CE ISO9001

-

cotton carding machine:

-

cotton spinning machine

Quick Details

-

Application:

-

Spinning Line

-

Production Capacity:

-

95%-98%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

tongjia

-

Model Number:

-

TJSM-01

-

Dimension(L*W*H):

-

37600x1000x2300mm

-

Weight:

-

20 TONS

-

Power:

-

Depend

-

Certification:

-

CE ISO9001

-

cotton carding machine:

-

cotton spinning machine

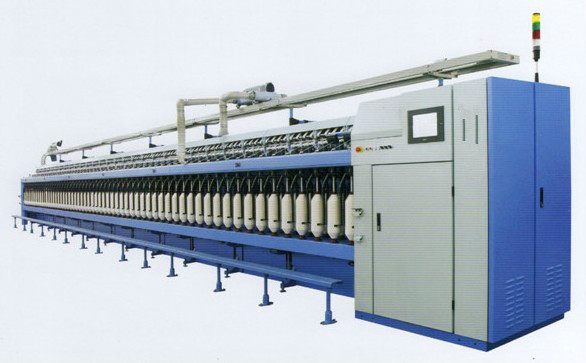

RING SPINNING PRODUCTION LINE

1. BLOW ROOM--Cotton plucker, Mixing opener

FA002 round automatic plucker is suitable for the plucking of all classes of raw cotton, cotton chemical fiber and middle-long fiber shorter than 76mm. It’s the first procedure of the machine and consists of pulley, central axis, expansion tube and ground rail, etc. And external wall board. A002D is used singly. And the FA002 can be used in double. For large number of raw material varieties with great differences, FA002 improve the number of mixed bale and reduce the mixing units, helps to improve working quality.

Suitable for all classes of raw cotton (usually for those with high maturity and higher class). Placed in the front of automatic plucker, and transmit the small block brought by the automatic plucker raw cotton into the machine with the aid of A045Dcondenser (additional), open and remove some impurities and dusts, then suck the raw cotton into the platform with its condenser.

2. Carding machine

unique patented three-roller stripping cotton;

increase in the gill plate carding roller;

After the first three additional two fixed cover;

brake fast-Astoria;

used Step-pressure roll;

use of Adolf timing belt drive;

about closed-end security cover;

Main specifications:

|

the scope of application |

apply to the local cotton and chemical fiber spinning pure or blended with Mianjuan feeding. |

|

|

quantitative production |

3.5 ~ 6.5 g / m |

|

|

production |

35 kg / h |

|

|

working width |

1000 mm |

|

|

additional pieces of comb |

roller carding a board |

|

|

Cover fixed after 2 |

||

|

cover fixed before the |

||

|

drawing a multiple of total |

67 ~ 120 |

|

|

Spurs roll diameter of the work |

Φ250 mm |

|

|

barbed roller speed of the work |

cotton |

1070 to / |

|

Fiber |

980 / |

|

|

work of the cylinder diameter |

Φ1289 mm |

|

|

cylinder speed of the work |

Cotton |

360 / |

|

Fiber |

330 / |

|

|

the work of Adolf diameter |

Φ706 mm |

|

|

speed of the work of Adolf |

21.3 ~ 38.2 to / |

|

|

cover the number kan

|

40/106 |

|

|

flat rate of |

Cotton |

177 214 266 mm / sub |

|

Fiber |

81 98 122 mm / sub |

|

|

sliver application of the tube

|

Φ600 × 900 mm

|

|

|

dust |

Cylinder triangle-Astoria, gill cover roller cover, curtain delivery vehicles belly 3 miscellaneous cleaning |

|

|

suction air flow in a row |

1300 m 3 / h |

|

|

wind |

-500 ~ -600 Pa |

|

|

total power installed capacity |

4.4 kW |

|

|

main motor |

3.3 kW |

|

|

Adolf drive motor |

1.1 kW (frequency, a significant number of users may choose to use) |

|

|

area (length × width) |

3809 × 2092 mm |

|

|

weight of the whole machine |

About 4500 kg |

|

3.Draw frame

D rawing frame has absorbed the advanced techniques, and adopted mechanical-electrical integration design. Reasonable drafting equipment, convenient operation. Percentage of variation is below 25%, it has reached advanced level of high intelligent, high output and high quality

Technical parameter

:

Range of Application:22-76mm

Delivery:2

Output speed:200-600m/min

Distention method:three-up three-down pressure rod and deflector roll

curving distention.

Total Draft:4-13

Feeding radix:6-8 radix

Sliver can specification:(mm)

feeding diameter400,600,800,height:1100,900

output diameter300,350,400,Height:1100,900

Feeding method:gantry creel active feeding

Can-changing method:chain handspike

Motor:main motor 380V 3.5/0.8KW 4P/16P

Wind indrafting motor 380V 0.75KW

Can-changing motor 380V 0.25KW

Dimensions(LxWxH):2000x800x1910(mm)

Weight:2000kgs

4.Roving machine

FA497/FA498 TRIAXIAL COMPUTERIZED ROVING FRAME

FA497/FA498high speed suspend flyer Roving Frame is driven by three inverter motor with simple structure and advanced program automalizalion, reversing rapidly and sensitivity avoid the sliver faults during reversing The frame is equipped with sliver breakage protection system and is one new generation practical model Flyer and winding sections can adopt gear transmission,the gears are precisely processed ,the running is smoothy,speed is high and the noise is Iow. POWER 16KW

Flyer and winding components can adept ciicular arc gears timing belt to drive te ensure high running speed,low noir and easy maintenance.

No mechanical forming. No cone drum

5.Ring spinning machine

|

Spindle number |

1008,960,504, 492 , 480 , 456 , 444 , 420 , 408 , 396 , 384 , 372 , 360 , |

|

Dia.of diameter(mm) |

38, 42 , 45 |

|

Tuble length(mm) |

205, 230 |

|

/Spun yam count(tex) |

6-96( 100-6NE ) NORMAL 13-36 ( 45-16NE ) |

|

Drafing times |

10-50 |

|

Twist range |

260-1500 T/M |

|

Spindle speed range(r/min) |

12500-18500; NORMAL 12500-16300 |

|

POWER |

16KW |

|

Twist |

Z, Z OR S |

|

Roving package(mm) |

135*320, 152*406 ( MAX ) |

|

Spinnable fiber |

Cotton,cotton-type chemical fibre and medium synthetic fibre up to 65mm or their blends |

6. Cone winder

type: double groove drum

every state ingot: 60,80,100,120. (To 100 for the standard form)

network yarn from the spindle speed: 254 mm.

Introduction lead yarn: 152 mm

yarn network speed: 140,160 m / min.

into a tube size: Φ 200 × big 152 mm long, steep gradient 6o.

groove drum : Φ82.5 mm diameter, 2 and a half laps stacked anti-tank (bakelite or metal groove drum

groove drum pulley diameter: Φ150 mm.

off from the yarn stopped device: each set of Zhan alone.

tension yarn plant ching: Introduction hook yarn, yarn clearer guide plate and yarn set of devices. (Tension has set 18.2,7.4,3.5 weight of three grams).

Anti-stacked devices: electrical switch box with no contact occasional electronic switches in the operation of a motor to open a stop speed ups and downs, the time interval in accordance with the speed necessary adjustable support an electronic display.

size: 13,600 mm long, 1400 mm wide and 1960 mm high. (Adjustable)

drive:

Active motor: two, JF0-31-6-1.1 kilowatts, to 960 / points, to 30 cents a belt drive shaft groove drum.

Auxiliary motor: a, FW-11A-6-.18 kilowatts, to 960 / points off yarn automatic transmission boxes suspended