- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

2800 r.p.m

-

Spindle Bore(mm):

-

25.4

-

Width of bed (mm):

-

40 mm

-

Spindle Motor Power(kW):

-

4

-

Max. Turned Length (mm):

-

500

-

Travel (X Axis)(mm):

-

500 mm

-

Travel (Z Axis)(mm):

-

300 mm

-

Place of Origin:

-

Guangdong, China

-

Dimension(L*W*H):

-

1300*600*1100

-

Brand Name:

-

Yowing

-

Model Number:

-

MC3015II

-

Voltage:

-

220V/380V/415V/440V

-

Weight (KG):

-

1500

-

Maximum processing length:

-

500mm

-

Maximum processing diameter:

-

300mm

-

Spindle speed:

-

1400-2800rpm

-

Total power:

-

4kw

-

Operation mode:

-

automatic

-

Control axis number:

-

2 axis

-

System code:

-

G code

-

Automatic feeding:

-

Optional

-

Weight:

-

1200kg

-

Size:

-

3200*1600*1500mm

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

500

-

Year:

-

new

-

Max. Spindle Speed (r.p.m):

-

2800 r.p.m

-

Spindle Bore(mm):

-

25.4

-

Width of bed (mm):

-

40 mm

-

Spindle Motor Power(kW):

-

4

-

Max. Turned Length (mm):

-

500

-

Travel (X Axis)(mm):

-

500 mm

-

Travel (Z Axis)(mm):

-

300 mm

-

Place of Origin:

-

Guangdong, China

-

Dimension(L*W*H):

-

1300*600*1100

-

Brand Name:

-

Yowing

-

Model Number:

-

MC3015II

-

Voltage:

-

220V/380V/415V/440V

-

Weight (KG):

-

1500

-

Maximum processing length:

-

500mm

-

Maximum processing diameter:

-

300mm

-

Spindle speed:

-

1400-2800rpm

-

Total power:

-

4kw

-

Operation mode:

-

automatic

-

Control axis number:

-

2 axis

-

System code:

-

G code

-

Automatic feeding:

-

Optional

-

Weight:

-

1200kg

-

Size:

-

3200*1600*1500mm

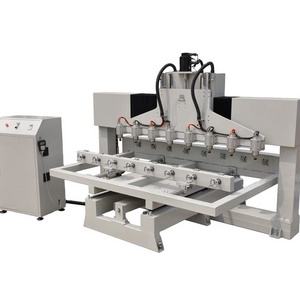

Product Description

Woodworking CNC lathe CNC profiling machine Multi-function woodworking copy lathe cnc milling machine Automatic cnc shaping machine

Features:

------More Mature Control Technology

This equipment adopts the international G code, the processing action control program is versatile, the work is fact and the machine and hardware processing center adopt the same control system which is more station and more accurate.

------More stable motion module

The machine tool adopts high-precision servo execution power output and adopts the internationally renowned brand of precision guide rail and ball screw drive ,which effectively improves the reciprocating operation accuracy of the equipment and effectively avoids the influence of dust on the machine tool.

------More Robust machine structure

The entire machine tool is cast and molded and high frequency precision machining is used to effectively improve the stability of

the machine tool

------Better after service

We have online after service to help you solve problem and free spare parts available.

After the world back to normal, we can travel as before, we will look around each Country and visit our customer.

This equipment adopts the international G code, the processing action control program is versatile, the work is fact and the machine and hardware processing center adopt the same control system which is more station and more accurate.

------More stable motion module

The machine tool adopts high-precision servo execution power output and adopts the internationally renowned brand of precision guide rail and ball screw drive ,which effectively improves the reciprocating operation accuracy of the equipment and effectively avoids the influence of dust on the machine tool.

------More Robust machine structure

The entire machine tool is cast and molded and high frequency precision machining is used to effectively improve the stability of

the machine tool

------Better after service

We have online after service to help you solve problem and free spare parts available.

After the world back to normal, we can travel as before, we will look around each Country and visit our customer.

Specification

|

item

|

MC3015

|

MC3015I

|

MC3015II

|

|

Max. Length of Workpiece (mm)

|

1500

|

1500

|

1400

|

|

Max. Spindle Speed (r.p.m)

|

1400-2800r.p.m

|

0-4000r.p.m

|

0-4000r.p.m

|

|

Spindle Bore(mm)

|

25.4

|

25.4

|

25.4

|

|

Width of bed (mm)

|

40mm

|

40mm

|

100mm

|

|

Spindle Motor Power(kW)

|

8.4

|

9

|

11

|

|

No. of Spindles

|

1

|

2

|

2

|

|

Control axis number

|

2 axis

|

3 axis

|

2 axis

|

|

System code

|

G code

|

G code

|

G code

|

|

Speciaty

|

1 pc at one time

|

2 pcs at one time

|

2 pcs at one time with brush sand

|

|

Weight

|

2000kg

|

2100kg

|

2300kg

|

|

Size

|

3200*1000*1200mm

|

3200*1000*1200mm

|

3200*1000*1200

|

Machine Details

Features of our machine

------

Spindle Qty

we could configure single spindle with two pcs cutter or one pc cutter, single spindle could configure chuck, two cutters could do rough turning and finish turning at the same time for high efficiency and surface quality. (Double spindles has stop to produce again. In fact,the model is not good to the turning the wood products, it is very slow when turning the big sizes column,and there have many defects at design to the Double Spindle lathe, Such as the Sanding, Centering, Programming,Upper Spindle Structural Stability etc)

------ Driving system

Adopt frequency conversion speed regulation system, could adjust the turning speed at any time to solve the problem of materials’ vibration.

------Machine cutters

The machine has 2 cutters (The Rough turning cutter and finish turning cutter work synchronously with layered process)

and so that improve the efficiency and work piece surface quality.

we could configure single spindle with two pcs cutter or one pc cutter, single spindle could configure chuck, two cutters could do rough turning and finish turning at the same time for high efficiency and surface quality. (Double spindles has stop to produce again. In fact,the model is not good to the turning the wood products, it is very slow when turning the big sizes column,and there have many defects at design to the Double Spindle lathe, Such as the Sanding, Centering, Programming,Upper Spindle Structural Stability etc)

------ Driving system

Adopt frequency conversion speed regulation system, could adjust the turning speed at any time to solve the problem of materials’ vibration.

------Machine cutters

The machine has 2 cutters (The Rough turning cutter and finish turning cutter work synchronously with layered process)

and so that improve the efficiency and work piece surface quality.

Operation panel

This is operation panel to inpur all information and sizes inside to control shapes.

Wood clamp unit

To hold the wood samples tightly , so make working stable!

Cutter base for tool change.

This base is with 4 cutters , every time change cutter here for different uses.

Cutter change top view.

From this photo you can see whole cutter base and clamp system.

Knife configuration

The knife is with knife bracket,locking block to make sure it is fastened enough and easy for grinding.

More Knifes for option.

tungsten steel knife and white steel knife for option and many sizes available.

Processing Wood Samples

Various cylindrical work piece, bowl sharp, tubular sharp and vehicle wood crafts, such as various staircase column, Roman column,general column, tables or chairs legs, washstand, wooden vase, wooden table, baseball bat, car wooden furniture, children' s bed column, etc.

Related Products

Multifunction cnc lathe with auto loading

Mostly for stairs armrest, hand rails,pillars.

Double spindles for 2 pieces processing at one time.

Mostly for stairs armrest, hand rails,pillars.

Automatic CNC lathe for long wood processing

Mostly for stairs armrest, hand rails,pillars.

Company Profie

"YOWING MACHINERY,Located in China woodworking machinery important town: Lunjiao, Focusing on the development of full range of furniture and wooden door machinery equipment,providing furniture and wood door companies with solutions for whole factory planning and automatical production lines,presenting our customers with excellent quality,efficient and stable products and high-quality service.

Yowing machinery, under all colleagues hardworking,our machines sold very well domestic and abroad,our services has been to almost 20 countries including asia, Russia, Brasil and Mexico,ETC.In 2018,We built up a service office in Binh Duong, Vietnam, and created a professional service team, to make sure can prove immediate service for our domestic and abroad customers.

2019,Yowing machinery, in order to help solve sanding difficulties, we start import and sell Origin of Italy Profile sand, provide more proper sanding materials for wood sanding, and metal sanding.2020, we will continue searching high quality overseas sanding materials, matching chinese machines and equipments, give one more option to our customers!"

Packing & Delivery

FAQ

1.How can i get the price?

-We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

2.What is your lead time?

-It depends on the order quantity and the season you place the order.

Usually we can ship within 7-15 days for small quantity,and about 30 days for large quantity.

3.What is your payment term?

-T/T,Western Union,MoneyGram,and Paypal.This is negotiable.

4.What is the shipping method?

-It could be shipped by sea,by air or by express(EMS,UPS,DHL,TNT,FEDEX and ect).Please confirm with us before placing orders.

5

.How do you make our business long-term and good relationship?

-1. We keep good quality and competitive price to ensure our customers benefit ;

-2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Hot Searches