- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V 50HZ

-

Power:

-

13KW

-

Dimension(L*W*H):

-

3620*2160*2100 mm

-

Weight:

-

5000 kg

-

Bowl Side Welding:

-

Ultrasonic Heater

-

Bowl Bottom Heating:

-

Hot Air

-

Paper Material:

-

Single or Double PE Coated Paper/Kraft Paper

-

Online technical support:

-

Provided

-

Field installation, commissionin:

-

Provided

-

Field Training:

-

Provided

-

Certification:

-

CE/ISO9001

Quick Details

-

Production Capacity:

-

50 pcs/min

-

Place of Origin:

-

Zhejiang, China

-

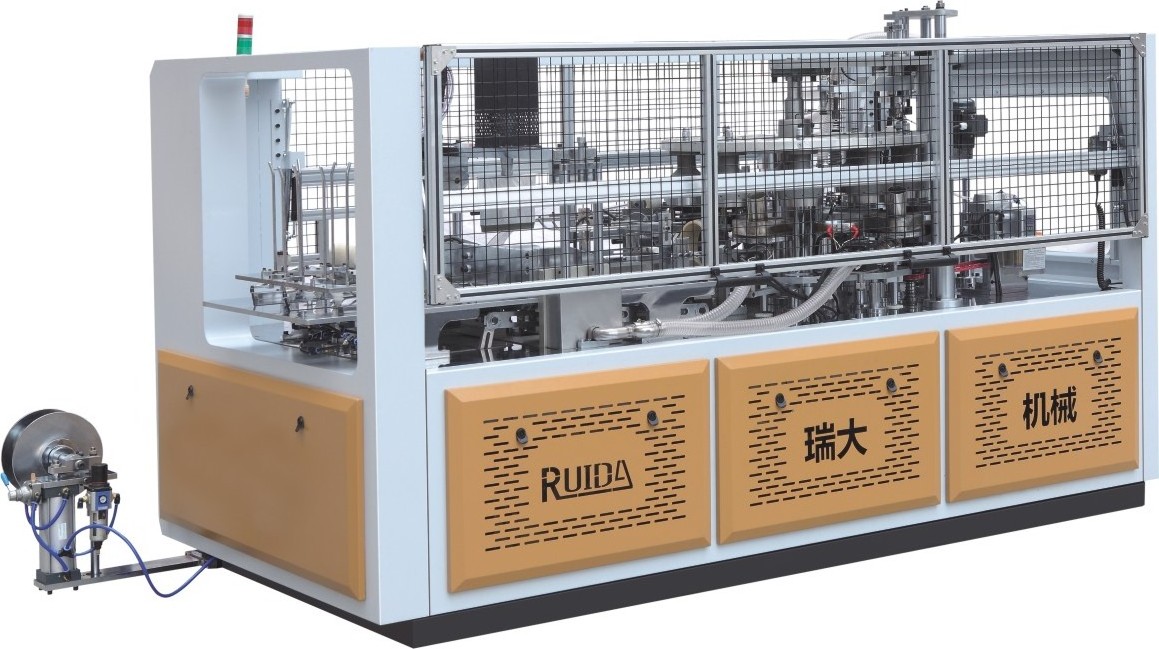

Brand Name:

-

RUIDA

-

Voltage:

-

220V/380V 50HZ

-

Power:

-

13KW

-

Dimension(L*W*H):

-

3620*2160*2100 mm

-

Weight:

-

5000 kg

-

Bowl Side Welding:

-

Ultrasonic Heater

-

Bowl Bottom Heating:

-

Hot Air

-

Paper Material:

-

Single or Double PE Coated Paper/Kraft Paper

-

Online technical support:

-

Provided

-

Field installation, commissionin:

-

Provided

-

Field Training:

-

Provided

-

Certification:

-

CE/ISO9001

Products Description

KFC Large Sized Paper Bucket Forming Machine Automatic Big Paper Bowl Machine

|

Model

|

RD-XT-200

|

|

Cups Specifications

|

28-190 oz

|

|

Paper Cup top diameter

|

120-220 mm

|

|

Paper cup height

|

100-200 mm

|

|

Weight

|

5000 kg

|

|

Total Power

|

220/380V 50HZ 13KW

|

|

Paper Material

|

180-500 g/m²

|

|

Speed

|

35-50 pcs/min

|

|

Packing Dimensions

|

3620*2160*2100 mm

|

|

Shipping Details

|

By sea/air,according to customers' requirements.

|

|

Other Products

|

Paper cup machinery,die cutting machine,Paper cup printing machine,cup top flatten machine and other products.

|

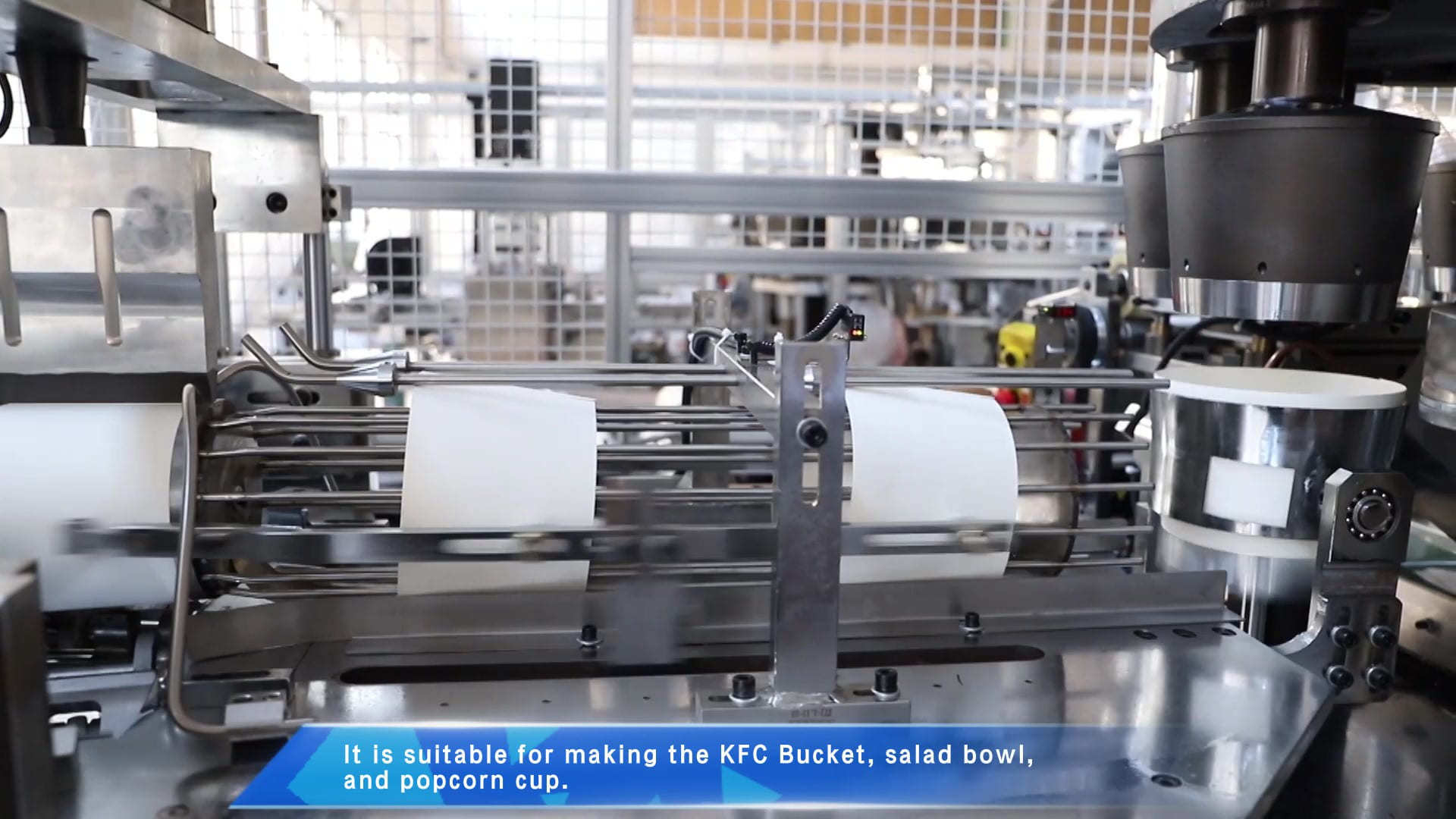

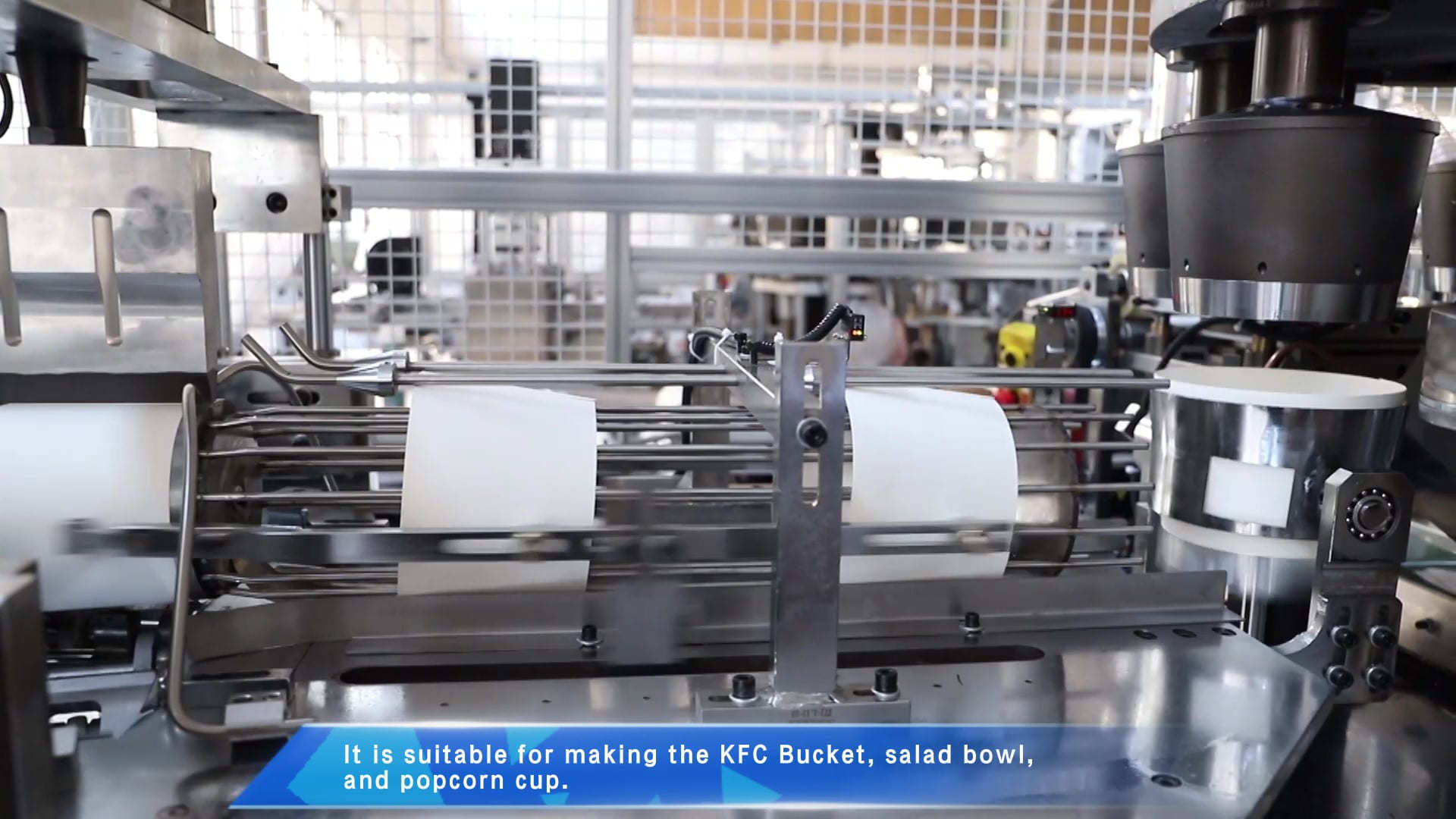

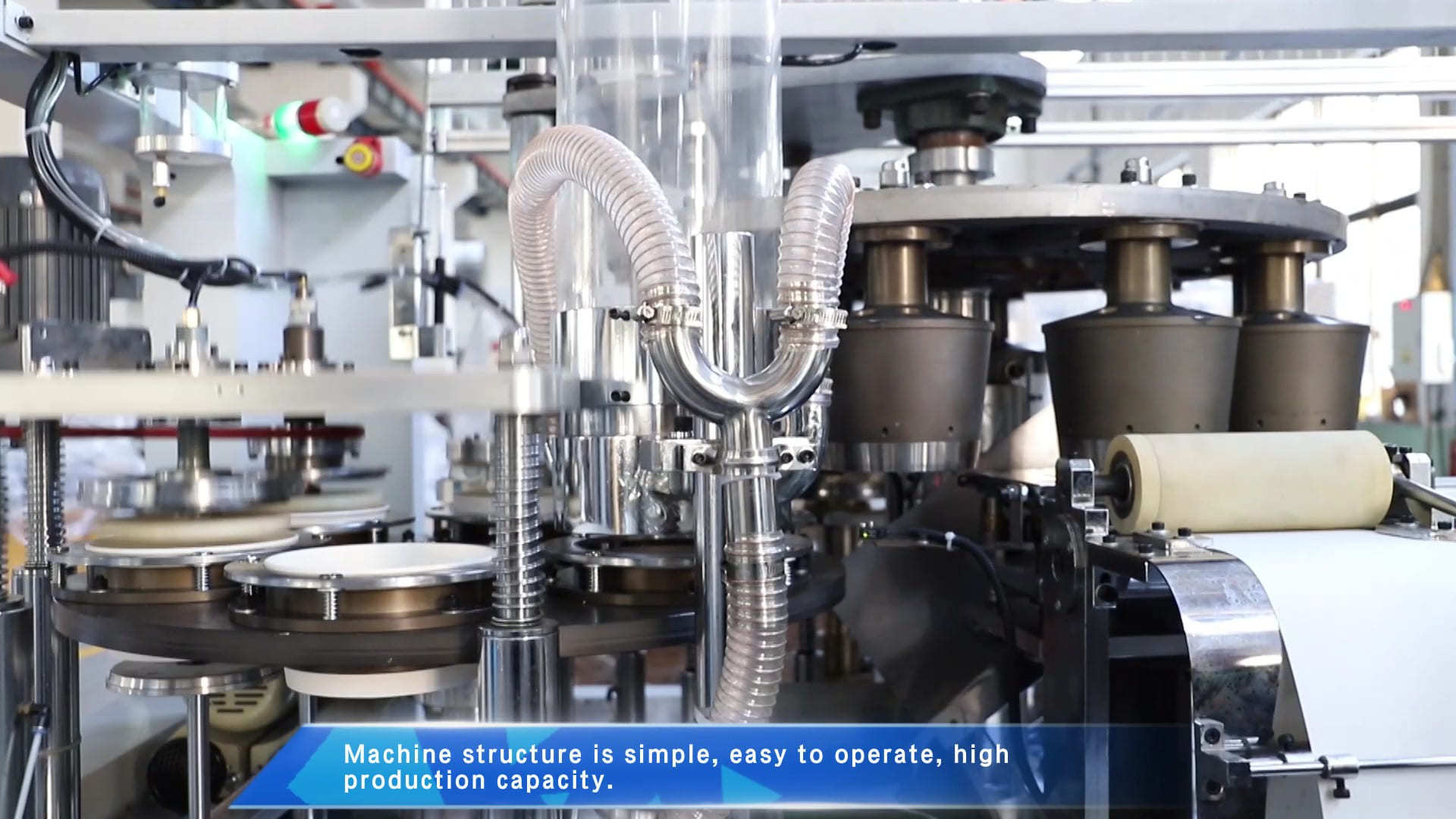

RD-XT-200 popcorn cup machine comes with open intermittentindexing cam mechanism,gear transmission,longitudinal axisstructures. The whole machine adopts automatic lubricationsystem, which makes all mechanical parts working much moresmoothly.

It is suitable for making the KFC, salad bowl, and popcorn cup.

Manufacturing Technique

Whole gears, shafts, open cam, grooved wheel and indexing plate high-precision transmission system.

All transmission mechanical parts are strictly selected of specific materials, and undergo specific processing techniques, such as quenching, surface phosphating, blackening, carburizing hardening, curve grinding, etc., to ensure that the machine has good stability and service life after precious assembling.

Hot Searches