- Product Details

- {{item.text}}

Quick Details

-

Name:

-

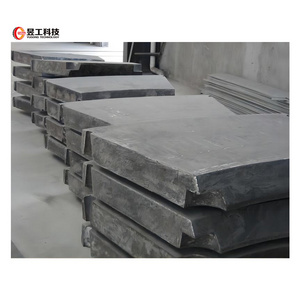

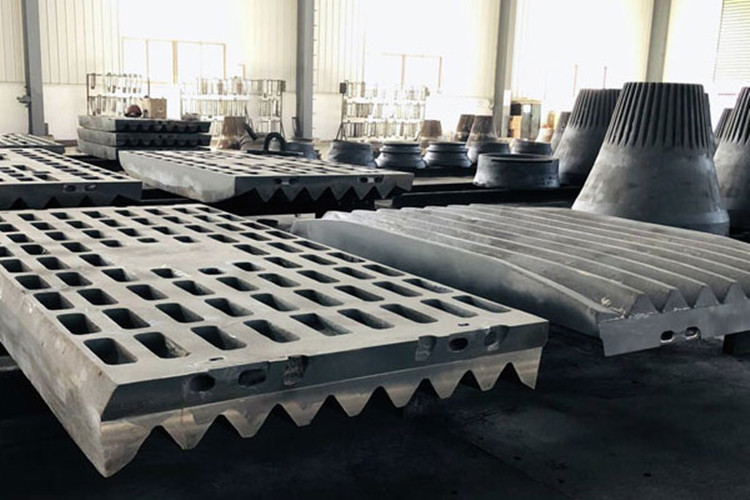

Cement Kiln Segments High Hardness Alloy Liner Plates

-

Ball mill:

-

dia3.2 / dia3.4 /dia3.8 /dia4.2

-

Blank:

-

Casting/Forging as per drawing

-

Heat Teatment:

-

QT/Hardening/Carburizing

-

Manufacturing Process:

-

Hobbing/Milling/Shapping

-

Surface treatment:

-

Polishing/Grinding/ Painting/Anti Rust Oil

-

Size:

-

OD max to 1500mm

-

Certificate:

-

ISO9001:2008

-

Application:

-

Steel factory, Rolling Mill etc.

-

Drawing Format:

-

ODM/OEM

Quick Details

-

Weight (KG):

-

10

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Ruding

-

Name:

-

Cement Kiln Segments High Hardness Alloy Liner Plates

-

Ball mill:

-

dia3.2 / dia3.4 /dia3.8 /dia4.2

-

Blank:

-

Casting/Forging as per drawing

-

Heat Teatment:

-

QT/Hardening/Carburizing

-

Manufacturing Process:

-

Hobbing/Milling/Shapping

-

Surface treatment:

-

Polishing/Grinding/ Painting/Anti Rust Oil

-

Size:

-

OD max to 1500mm

-

Certificate:

-

ISO9001:2008

-

Application:

-

Steel factory, Rolling Mill etc.

-

Drawing Format:

-

ODM/OEM

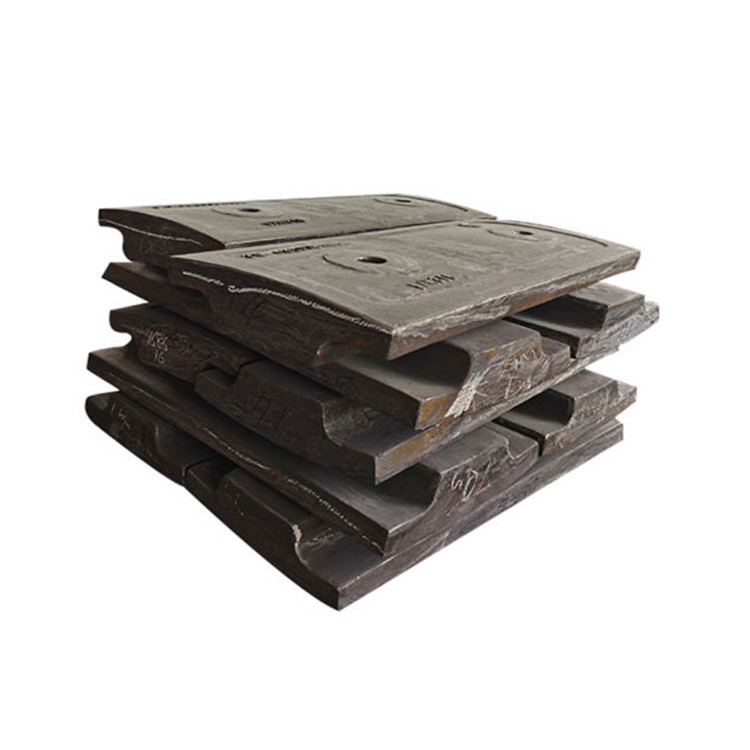

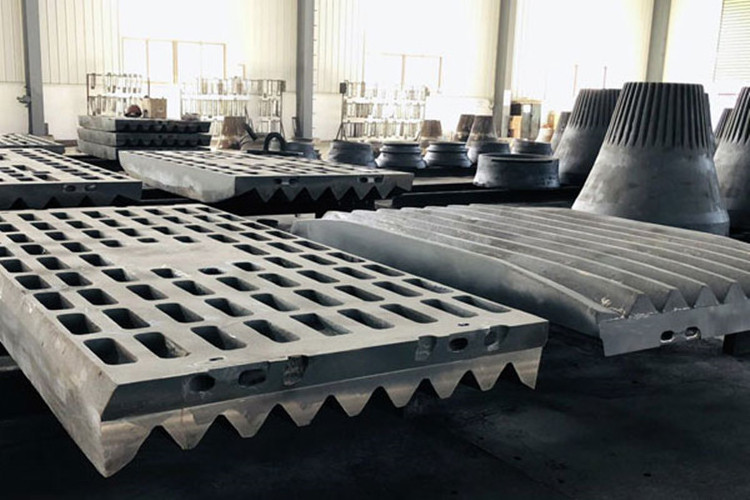

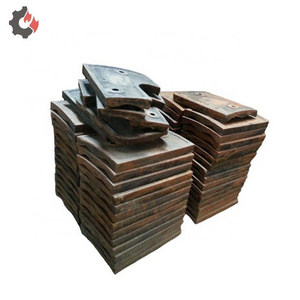

Ball mill liners are a kind of very important spare parts of the ball mill. Because they are frequently worn and consumed during the operation of the ball mill, it is necessary to replace them in time to prevent machine failure.

Ruding Steel provides a variety of ball mill liners with different shapes and materials for customers to choose from.

Application :

* Armed plates for clincker silo in cement plants.

* Wear plates for chutes, material bunkers for port machinery.

* Material hoppers in steel mills.

* High abrasion plates for material bin for port maachinery.

* Wear plates for coal hoppers.

Specifications:

Ruding Steel can customize cement mill liner plate as per customer's specifications and requirements

Manufacturing Process

Forging/Casting – Normalizing & Tempering – Proof Machining- Quenching & Tempering – Finish Machining

–

packaging

–

delivery.

1. OEM and customized service.

2. Full machining, primer coating, surface treatment.

3. Complete material testing process.

4. Quality control

Please contact us for more information and quotations.