- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Vesteon or OEM

-

Warranty:

-

3year

-

Model Number:

-

dz

-

Product Name:

-

Good perform automobile alloy wheel alloy rim for cars

-

CB:

-

0-200mm

-

Certification:

-

ISO , VIA , SFI , TUV , TS16949 ect.

-

Package:

-

Soft Cap and carton outside or as customer's requirements

-

finishing:

-

sliver ,black ,machined face/lip ,HS/HB ,VACUUM CHROME ,CHROME

-

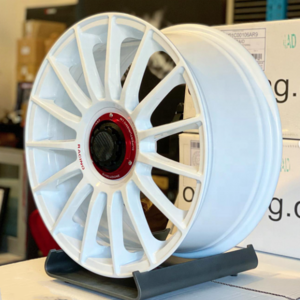

Color:

-

White ,yellow ,red .blue ,black ,sliver ...

-

Suitable Car Make:

-

Car Racing Alloy Rims , car ,SUV ,JEEP CAR ect.

Quick Details

-

Finishing:

-

sliver .black , machine face ,machine lip , chrome ,HS ,GM

-

Width:

-

5.0j-15.0j

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Vesteon or OEM

-

Warranty:

-

3year

-

Model Number:

-

dz

-

Product Name:

-

Good perform automobile alloy wheel alloy rim for cars

-

CB:

-

0-200mm

-

Certification:

-

ISO , VIA , SFI , TUV , TS16949 ect.

-

Package:

-

Soft Cap and carton outside or as customer's requirements

-

finishing:

-

sliver ,black ,machined face/lip ,HS/HB ,VACUUM CHROME ,CHROME

-

Color:

-

White ,yellow ,red .blue ,black ,sliver ...

-

Suitable Car Make:

-

Car Racing Alloy Rims , car ,SUV ,JEEP CAR ect.

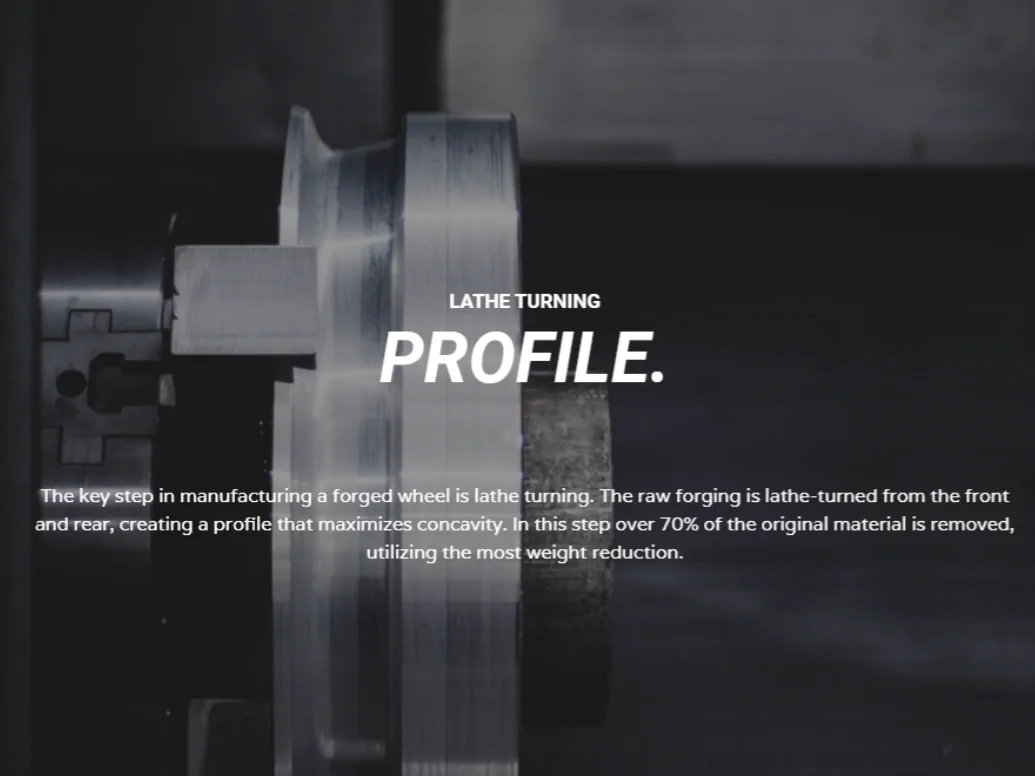

FORGED E

NGINEERED ART.

We at continue to be dedicated in producing not only wheels, but also a lifestyle that reflects a passion for creativity and a desire for delivering the finest wheels. Performance and longevity is the hallmark of a great wheel. That is why we place a heavy emphasis on precision designing, precise engineering and expert craftsmanship. Aiming to achieve the highest quality wheels in its class.

We at continue to be dedicated in producing not only wheels, but also a lifestyle that reflects a passion for creativity and a desire for delivering the finest wheels. Performance and longevity is the hallmark of a great wheel. That is why we place a heavy emphasis on precision designing, precise engineering and expert craftsmanship. Aiming to achieve the highest quality wheels in its class.

THE FOUNDATION.

THE FOUNDATION.

ENGINEERING | FEA TESTING

Step 1:

Our team at with over 20 years of combined forged wheel experience allows us to have full control over the quality of our process. Each order goes through Finite Element Analysis (FEA) testing to ensure the most optimal combination of lightweight, durability, and strength.

6061 T6 AERO SPACE FORGED

MATERIAL.

Step 2:

It was a perfect match as our forging supplier.

QUALITY CONTROL.

QUALITY CONTROL.

Step 3:

Each center after turning is remeasured and goes through a quality control check list to ensure each part meets our standards and tolerances before the milling process begins.

WHERE DESIGN COMES TO LIFE

MILLING.

Step 4:

After the milling process is completed, each section of raw milled aluminum needs to go through many stages of Hand Filing, Deburring, Buffing and Ceramic Bead High-Luster Polishing before it is ready for its ultimate finish. This is a vital stage for our craftsmen to prep each wheel before its coating. After each wheel is filed and sculpted the wheels go through a detailed check list with zero compromises.

FINISHING.

Step 5:

The most rewarding part of the manufacturing process is the finish stage. we are always learning new ways in achieving the utmost beautiful finishes in our industry.

Each component of the wheel is offered with a Gloss, Satin or Texture finish of your choice.

ASSEMBLY.

Step 6:

The assembly stage is one of the most critical stages in the manufacturing stage. First step is to check the run-out of every wheel to guarantee the wheels are balanced to eliminate vibrations and wobbling. We chose to use Digital Snap-On® Torque Wrenches vs generic torque wrenches. One of the advantages is that it can more precisely control the amount of torque that’s applied to a bolt without losing any torque capacity.

Every year or 5,000 cycles we will calibrate our wrenches to ensure accuracy and safety. After each bolt and nut is torqued we mark them and have our expert assemblers sign off the wheels for packaging.

Looking forward to hearing from you