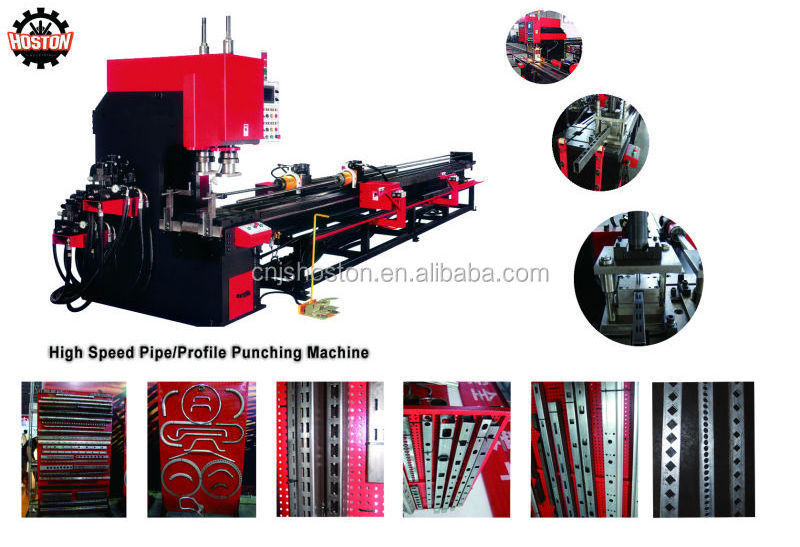

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3.5m, 6m, 12m

-

Weight (T):

-

4

-

Material:

-

Aluminum, Copper ,Stainless Steel

-

Pipe Type:

-

Round Tube, Square Tube, Rectangle Tube

-

Profile Steel:

-

Angle Steel, H-beam, I-beam

-

Operational function:

-

jogging/automatic

-

TFT human machine interface:

-

Human machine interface

-

Memory Function:

-

can be stored and memorized

-

Lubrication oil:

-

Sinopec or Exxon mobil

-

Hydraulic Oil:

-

46#

-

Nominal Force (kN):

-

4000

-

Certification:

-

CE, ISO, CQC, BV

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Hoston

-

Voltage:

-

220V, 380V, 415V

-

Dimension(L*W*H):

-

3.5m, 6m, 12m

-

Weight (T):

-

4

-

Material:

-

Aluminum, Copper ,Stainless Steel

-

Pipe Type:

-

Round Tube, Square Tube, Rectangle Tube

-

Profile Steel:

-

Angle Steel, H-beam, I-beam

-

Operational function:

-

jogging/automatic

-

TFT human machine interface:

-

Human machine interface

-

Memory Function:

-

can be stored and memorized

-

Lubrication oil:

-

Sinopec or Exxon mobil

-

Hydraulic Oil:

-

46#

-

Nominal Force (kN):

-

4000

-

Certification:

-

CE, ISO, CQC, BV

Future:

a. The TFT HMI (human-machine interface) display, Touch Screen settings, NC control system, precise servo motor positioning, module storage memory function.

b. Structure : Steel plate welded structure

c. Mould replacement: change the die easily without adjusting the dies to reduce the mould damage rate and pipe fittings rejection rate due to the dies setting error. Skilled workers can change the mould within 10 minutes.

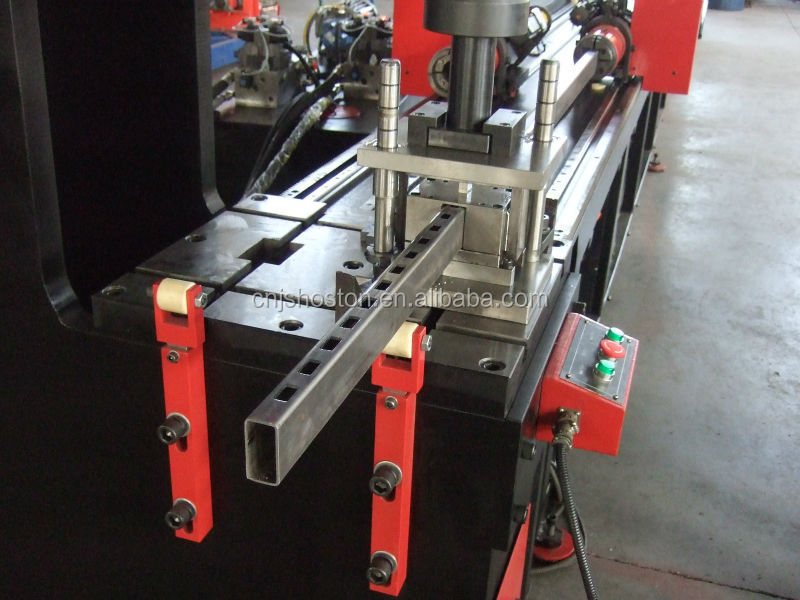

d. Punching Category: 1.single hole punching; 2.double hole punching; 3.Isometric hole punching; 4. none- Isometric hole punching; rotary punching.

e. Hydraulic and Servo System:

1. Step-less operation adjustment, hydraulic loops designed with zero load, combined with extremely low frequency oil pump motor, effectively reduced noise, increased motor efficiency and service duration.

2. When the oil cylinder is moving downward, the machine is designed with hydraulic difference driving loops rated at high or low RPM .it is also featured with high speed downward moving, low speed processing and hi-speed position resume .it is available to increase the formation stability of work pieces during puncturing .in addition to increasing the activation speed, it can effectively reduce HP load to save electrical energy.

3. The electrical control system is designed with the human machine interface, range adjustment use digital scale, setting low speed position, floor level position, and operation precise and easy.

4. Cylinder stroke 130mm (can be set), throat depth 300mm , available for forward and backward 150mm moving accessibility. Designed with the Italy-made digital scale with high precision.

Equipment Production Process:

Feed - clamp - fix position - start automatic - punch - unload

Application:

Square tube, rectangle pipe, round pipe, H-bem, I-beam, C-channel, Angle Steel and any other pipe punching, Punch material ; all kinds of iron, aluminum, copper ,stainless steel and so on.

|

1 |

Model |

TPM-50 |

|

|

2 |

Aperture and thickness |

Φ50×τ3~Φ16×τ11mm |

|

|

3 |

Aperture |

round pipe |

Φ16~Φ120 mm |

|

Square tube |

20×20~150×150 mm |

||

|

rectangle pipe |

15×30~60×150 mm |

||

|

Angle iron |

30×30~75×75mm |

||

|

channel iron |

25×50~60×120mm |

||

|

4 |

Hole distance |

0.1mm~3500mm |

|

|

5 |

Punching speed |

1.5sec/hole , 150mmStroke |

|

|

6 |

Longest distance between holes |

3400mm |

|

|

7 |

Standard length |

3500mm(can be Lengthened) |

|

|

8 |

Max feeding speed of servo |

3500mm/min |

|

|

9 |

Main Motor Power |

5.5Kw |

|

|

10 |

Engineering Motion Classification |

1, Single puncturing operation |

|

|

2,Irregular interval puncturing |

|||

|

3,Regular interval puncturing |

|||

|

4. 360°rotating puncturing |

|||

|

11 |

TFT human machine interface |

Human machine interface |

|

|

12 |

control system |

HITECH touch controllable display setting ,Chinese and English exchange |

|

|

16 |

Memory Function |

can be stored and memorized 0-99 groups processing mode |

|

|

17 |

Overall Dimension |

4500×1500×2300mm |

|

|

18 |

Weight |

3000Kg |

|