The electrical equipment including contactor, converter and PLC can be designed according to our customers' requirements. We can provide both International brand and Chinese brand like. Price will be based on the equipment selected.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fullwin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Based on the specific requirements

-

Power (kW):

-

50

-

Weight:

-

2000 KG

-

Raw material:

-

PP PE PVC Granules Powder

-

Usage:

-

Plastic Extrusion

-

Product Type:

-

Extrusion Production

-

Motor brand:

-

Beide Siemens

-

Screw:

-

Single Screw

-

Control:

-

PLC+Touch Screen

-

Cooling way:

-

Water Cooling+Air Cooling

-

Original:

-

Qingdao ,China

-

After-sales Service Provided:

-

Engineers

-

Speed:

-

25-35m/min

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fullwin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Based on the specific requirements

-

Power (kW):

-

50

-

Weight:

-

2000 KG

-

Raw material:

-

PP PE PVC Granules Powder

-

Usage:

-

Plastic Extrusion

-

Product Type:

-

Extrusion Production

-

Motor brand:

-

Beide Siemens

-

Screw:

-

Single Screw

-

Control:

-

PLC+Touch Screen

-

Cooling way:

-

Water Cooling+Air Cooling

-

Original:

-

Qingdao ,China

-

After-sales Service Provided:

-

Engineers

-

Speed:

-

25-35m/min

Main Product

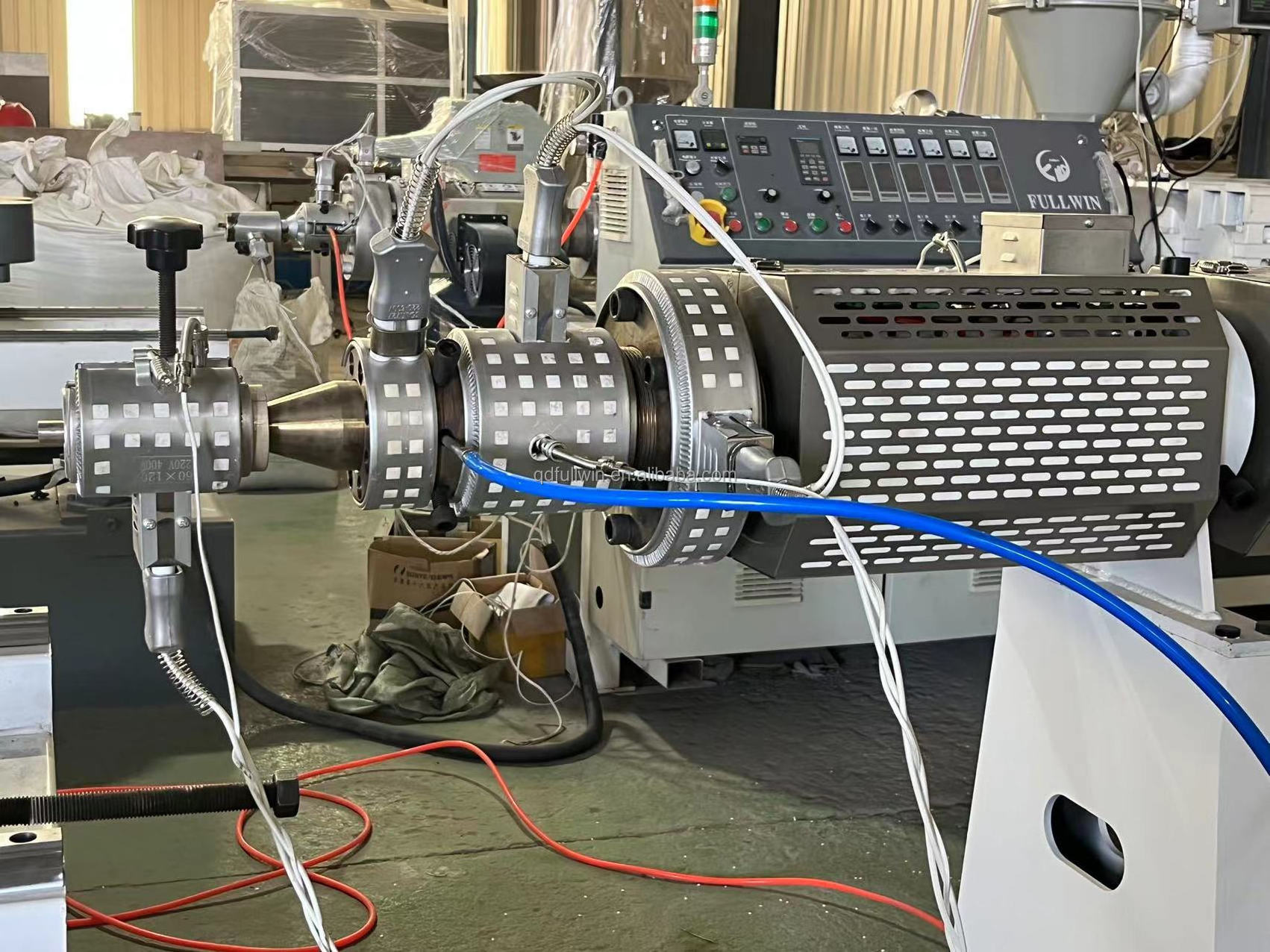

SJ-65/30 High speed single-wall corrugated pipe machine

FULLWIN plastic single-wall corrugated pipe production line is developed by our company independently. It adopts gears to run moulds so as to realize water circulating cooling of the products, which also ensures high-speed production, nice and smooth

inner and outer pipe wall

corrugation. These corrugated pipes are especially used in wires of up-market cars, disposable hookah pipe and electrical conduit pipe. The high speed machine production speed can reach 20-30 m/min.

|

Item

|

Name

|

Quanitty

|

|

1

|

Vacuum Feeder and Hopper Dryer

|

1 set

|

|

2

|

SJ-65/30 Single Screw Extruder (PLC control system)

|

1 set

|

|

3

|

Corrugated pipe die head

|

1 set

|

|

4

|

Core bar and mouth mould

|

1 set

|

|

5

|

Pipe forming Mould(16-50mm)

|

1 set

|

|

6

|

Corrugated pipe forming machine

|

1 set

|

|

7

|

Double station Winding machine

|

1 set

|

|

8

|

Free spare parts

|

19 pcs

|

Details of our product

Single Screw Extruder

Vacuum Feeder

Fullwin professional designed feeder which can operate stably for a long time.

Special feeder for PVC powder

When the raw material is PVC powder, we use other kind of feeder to carry them.

Hopper Dryer

The hopper dryer can dry the raw material by hot air to improve the next heating efficiency.

Hopper

The high speed single wall corrugated pipe making machine is equipped with large capacity hopper.

Drying temperature

The drying temperature of different material is determined by the specific raw material.

Single Screw

High speed single wall corrugated pipe machine is equipped with our professionally designed screw which can effectively process different raw material.

Heating Barrel

The heating collar takes new technology which can save about 30%

electricity consumption when stop heating

.

Gear Box

The material of our gear box are all high hardness steel. The gears tooth also have special treatment, which ensuring the long-time operating.

Electrical equipment

Die head

Mouth mould & Core bar

FULLWIN’s new design, the core bar and the mouth mould fit together. When changing the pipe size,the operater can just replace the whole part instead of changing the core bar and mouth mould separately like the old design.This can save about 1.5 hour on changing and cleaning the mould.

Forming machine

Forming mould

The forming moulds of high speed corrugated pipe making machine are treated specially, just for perfectly meeting our customers' needs.

Plate

The plate of the forming machine has been redesigned to make the whole machine operate more stably.

Auto cutter

Forming machine is equipped with auto cutter that has the extruder meter counting display.

Double Station Winding Machine

The winding machine using torque motor can collect the pipes efficiently. Its counter can adjust the winding speed by induction. What is more, by pneumatic self-locking switching, it can operate and stop automatically.

Single Wall Corrugated Pipe Product Application

Certification

FULLWIN Advantages

Reliable Products & Timely Assistance

Fullwin has made a lot of achievements in the plastic industry. Our eternal objective is to provide efficient and environment-friendly machine to our clients. Most importantly, we are happy to help our customers timely for that can be of benefits to get a win-win result!

Strong Team Work

Fullwin is composed of a group of energetic and optimistic guys. Our team always help with each other. We believe only in this way can we build a well-known and honorable brand, making people around the world trust our brand and choose our brand.

Professional Advice and Guidance

We promise to provide Reliable Turnkey Project Service

1. We will provide the Feasibility Analysis Report.

2. We will provide the model selection and technical parameter.

3. We will provide the design for the plant and electric power accounting for the facilities.

4. We will provide the design according to the product requirements.

5. We will provide technique training for operator.

6. We will provide solution for the practical problem during the production.

7. We will provide turnkey project to customers

After Sales Service

1.After all machines are delivered to customer’s factory, dear customer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc.

2.Fullwin will prepare for visa application for our engineers, who are responsible for guidance of machine installation and testing at the Buyer’s factory.

3.The customer will buy the round-trip air ticket for Engineer if visa application is approved. The customer is also responsible for bearing expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

4.Engineer will give free training lessons to labors in buyer’s factory.

5.If customer doesn’t request installation and commission by Fullwin's engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by customer.

FAQ

Q: How can we guarantee quality?

A: Always a pre-production sample before mass production;

Always final inspection before shipment.

Q: What can you buy from us?

A: Single Wall Corrugated Pipe Machine, Double Wall Corrugated Pipe Machine, PVC/ PP

Q: Why should you buy from us not from other suppliers?

Q: What service can we provide?

A: Accepted Delivery Terms: FOB, CFR, CIF, EXW, Express Delivery

Accepted Payment Currency: USD, EUR

Accepted Payment Type: T/T, L/C, MoneyGram, Credit Card, Western Union, Cash;

Language Spoken:English,Chinese,Spanish

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

A: Always a pre-production sample before mass production;

Always final inspection before shipment.

Q: What can you buy from us?

A: Single Wall Corrugated Pipe Machine, Double Wall Corrugated Pipe Machine, PVC/ PP

Water Supply Pipe Machine, WPC/PVC Profile and Sheet Profile Machine, PVC Fiber

Reinforced Pipe Machine etc.

Q: Why should you buy from us not from other suppliers?

A: Advanced production technology with design capability.

Reasonable price with good quality and best delivey time.

Our sales team will give prompt feedback within 24 hours.

Our sales team will give prompt feedback within 24 hours.

Professional after sales service system.

Q: What service can we provide?

A: Accepted Delivery Terms: FOB, CFR, CIF, EXW, Express Delivery

Accepted Payment Currency: USD, EUR

Accepted Payment Type: T/T, L/C, MoneyGram, Credit Card, Western Union, Cash;

Language Spoken:English,Chinese,Spanish

Q: Are you machinery factory or trading company?

A: We are machinery factory

A: We are machinery factory

Q:If we have very special request for the production line, could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

A:Experienced mechanical designer customized-design provided.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A: Our factory is in Jiaozhou Town, Qingdao City, Shandong Province, China. About 1 hours from Qingdao International Ariport.

A: Our factory is in Jiaozhou Town, Qingdao City, Shandong Province, China. About 1 hours from Qingdao International Ariport.

Recommend Products

Hot Searches