- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ

-

Power:

-

8.5kw

-

Dimension(L*W*H):

-

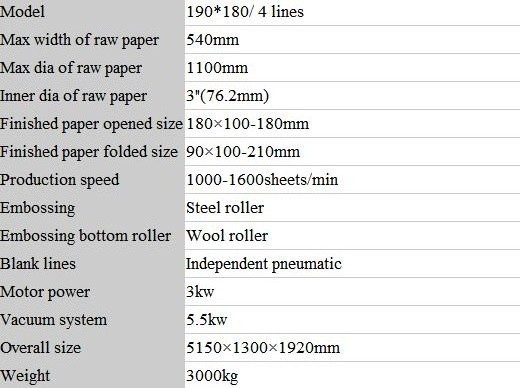

5150*1300*1920mm

-

Weight:

-

3000 kg

-

Warranty:

-

12 months

-

Marketing Type:

-

Hot Product 2021

-

Certification:

-

ce

-

faical tissue:

-

converting machine

-

solf facial tissue:

-

making machine

-

4 lines:

-

facial tissue folding machine

-

6 lanes:

-

facial tissue making machine

-

automatic:

-

facial tissue production machine

-

high speed:

-

tissue making machine

-

tissue paper:

-

interfolding machine

-

facial tissue paper:

-

V folding machines

-

facial tissue:

-

fold making machine

Quick Details

-

Production Capacity:

-

1000-1600 sheets/ min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PFK

-

Voltage:

-

380V 50HZ

-

Power:

-

8.5kw

-

Dimension(L*W*H):

-

5150*1300*1920mm

-

Weight:

-

3000 kg

-

Warranty:

-

12 months

-

Marketing Type:

-

Hot Product 2021

-

Certification:

-

ce

-

faical tissue:

-

converting machine

-

solf facial tissue:

-

making machine

-

4 lines:

-

facial tissue folding machine

-

6 lanes:

-

facial tissue making machine

-

automatic:

-

facial tissue production machine

-

high speed:

-

tissue making machine

-

tissue paper:

-

interfolding machine

-

facial tissue paper:

-

V folding machines

-

facial tissue:

-

fold making machine

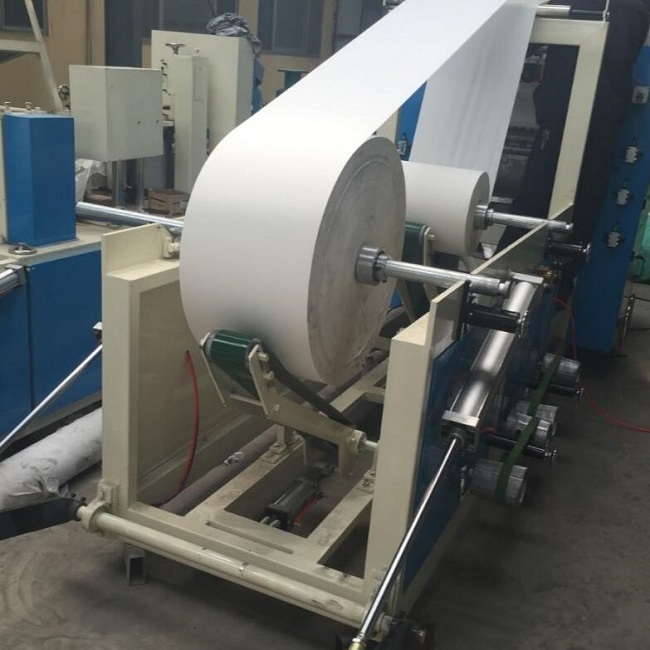

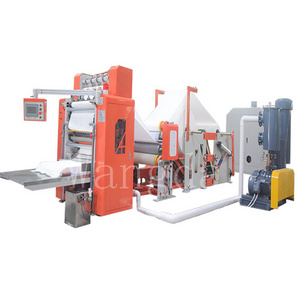

Saudi Arabia Poland Nigeria V folded 190*190mm 4 lanes towel facial tissue paper making machine factory

This facial tissue fold making machine adopt advanced PCL control technology, variable speed adjustment and matched with LCD screen operation control panel. The whole machine use timing belt drving, stepless speed adjustment. It makes the machine can fit more requirements of different gsm raw tissue paper, improved the finished soft facial tissue's quality and production capacity greatly.

Technical Parameters of our soft facial tissue paper folding machine

Automatic toilet tissue paper rewinding machine

Avaialbe width: 1200-3600mm

Working speed: 100-180 meter/min

Can rewind: 1-4 ply (optional)

Automatic trimming sealing rewinder machine adopts the international advanced PLC computer programming technology , frequency control, electronic brake and equipped with multi-touch screen human-machine interface operating system, and independent research and development of remote communication service system , they can always monitoring the operation of machinery ; newly developed forming a coreless roll rewinding system , the application of PLC programs wind column forming the new technology , as well as to achieve the effect of pipe without rewinding paper core , so that the whole market for many years invested in energy use fully upgraded, more ahead in technology in various applications .

Characters of our toilet paper rewinding machine

1, automatic paper tube replacement device , without artificial wearing paper tube , after the completion of rewinding automatically send finished , immediately reset rewinding within one minute can be adjusted to any kind of standard paper tube ;

2 , sent automatically after rewinding molding system that uses robotic arm pusher patented technology can successfully send the finished product , the minimum diameter of the finished product launch 60mm;

3, automatic trimming, gluing , sealing sync once completed, the device instead of the traditional waterline trimming to achieve foreign popular sticky tail trimming techniques , finished leaving the tail 10 ~ 18mm , easy to enable , to reduce the general Winder when the tail of the loss making machine , thereby reducing the product ;

4 , the use of advanced PLC programming technology , product realization process in rewinding loose multistage different tightness after the first tight resolve the finished result from long-term storage of loose paper core phenomenon.

Jumbo tissue paper slitting rewinding machine

Automatic folded tissue paper cutting machine

Packing of our tissue paper processing machines

PP film and wooden box, then load into 20" or 40" containers

Delivery of our toilet tissue paper machines

35-55 days after 30% T/T prepayment, 70% before delivery, and delivery from Qingdao seaport, it will take 3-4 days to finish the delivery (transport and duty clearance) from our factory to seaport.

| Item | Facial tissue folding machine | Facial tissue folding machine with auto log saw |

| Loading Container | 1*20"GP | 1*40''HQ |

The service that you can enjoyed from us for tissue paper manufacturing machines

1) Provide you professional suggestion about your tissue paper making or manufacturing project based on your workshop sizes, your budget, and your wanted production capacity.

2) Customize service is aviable from us, we can produce the tissue paper converting machines based on your wanted width, your wanted embossing pattern, and your local electricity Voltage( 220V,380V,420V); Design and produce the whole tissue paper making plants and tissue paper manufacturing plants for you, provide you one stop service from waste paper recycling to raw tissue jumbo production , then to final toilet rolls, facial tissue and napkin tissue manufacturing.

3) Engineers come to your factory site to help you install the machines ,and train your workers to operate our tissue paper machines skillfully, and instruct them to solve the common problems independently; All our engineers are rich experience for overseas installation and trainning.

4) Super after-sales service and give you technical support during your usage of our tissue paper machines, and instruct you how to maintain them; Guarantee steady spare parts supply to you; Old clients will enjoy discount and fast delivery for the new ordered tissue paper manufacturing machines.

5) 24 hours online service for facial tissue paper production machine

www.pefct.com

Skype: vastsea-777

What's app +8618561832088

www.paperpulpmoldingmachine.com

Our factory photo in snow

Napkin tissue paper folding machine

Foreign client for raw tissue paper production line

Brazil Tissue World Exhibition

You are warmly welcomed to contact with us for tissue paper machine's business !