1.The four column metal stamping press machine surface with anti-rust treatment,

2.The four column metal stamping press machine inner layer of plastic waterproof packaging,

3.The four column metal stamping press machine outer layer of thick wood or steel frame fixed,And then use a synthetic board

package.

Combined container transport, or separate container transport.

- Product Details

- {{item.text}}

Quick Details

-

Return Force (kN):

-

3150 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

woda

-

Year:

-

new

-

Voltage:

-

220-600V

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

4.5 T

-

Model Number:

-

YQ32

-

Motor Power (kw):

-

11 kw

-

Marketing Type:

-

New Product

-

Product name:

-

Power Press Machine

-

Power Source:

-

Hydraulic Power

-

Keyword:

-

Hydryalic Press

-

Function:

-

Pressing

-

Open height:

-

900 Mm

-

Advantage:

-

Easy Operation

-

Technology:

-

Advanced Technology

-

Key Words:

-

Hydralic Press

-

Color:

-

Grey

-

Power:

-

7.5KW-22KW

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Slide Stroke (mm):

-

400, 500, 600, 800

-

Ejector Force (kN):

-

2000

-

Return Force (kN):

-

3150 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

woda

-

Year:

-

new

-

Voltage:

-

220-600V

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

4.5 T

-

Model Number:

-

YQ32

-

Motor Power (kw):

-

11 kw

-

Marketing Type:

-

New Product

-

Product name:

-

Power Press Machine

-

Power Source:

-

Hydraulic Power

-

Keyword:

-

Hydryalic Press

-

Function:

-

Pressing

-

Open height:

-

900 Mm

-

Advantage:

-

Easy Operation

-

Technology:

-

Advanced Technology

-

Key Words:

-

Hydralic Press

-

Color:

-

Grey

-

Power:

-

7.5KW-22KW

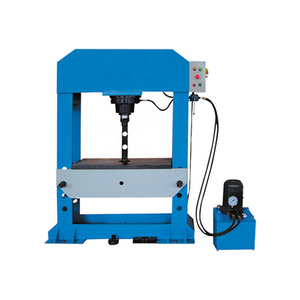

Metal stamping deep drawing machine four column 315ton hydraulic press

Product Description

The main performance characteristics:

315

ton Four Column Deep drawing Hydraulic press for stainless steel, Economical and Practical, Hydraulic control adopts to insert set valve intergrated system,decrease let out point.Movement reliability,durable and long life span.It is constant pressure to realize with calm in the first place and calm producedure two develop technology,have to insure press the function of delay time, The route of working pressure may be regulated in assigned scope, adopt buttons for centralized control.Can realization manual,Semi-automatic,automatic 3 operate form.

Application:

Hydraulic Press Machine 500 Ton With Hydraulic Cushion For Stretching, such as stamping, bending, flanging sheet stretching, and can be engaged in correction,

manhole cover making,

press fit, plastic products, powder products, compression molding.

|

Specification

|

|

Unit

|

315T-F

|

315T-A

|

315T-A-Z

|

315T-B

|

315T-C

|

|

|

Nominal force

|

|

KN

|

3150

|

3150

|

3150

|

3150

|

3150

|

|

|

Ejecting force

|

|

KN

|

50

|

50

|

63

|

63

|

63

|

|

|

Max. pressure of liquid

|

|

MPa

|

25

|

25

|

25

|

25

|

25

|

|

|

Stroke of slider

|

|

mm

|

400

|

500

|

500

|

600

|

800

|

|

|

Max. opening height

|

|

mm

|

700

|

900

|

900

|

1000

|

1250

|

|

|

Working table size

|

|

mm*mm

|

700x700

|

800x800

|

800x800

|

1000x1000

|

1260x1200

|

|

|

Ejecting stroke

|

|

mm

|

250

|

250

|

250

|

250

|

250

|

|

|

Speed of slider

|

Idle speed

|

mm/s

|

60

|

80

|

160

|

100

|

100

|

|

|

|

Working speed

|

mm/s

|

6-12

|

6-12

|

6-12

|

6-12

|

6-15

|

|

|

|

Return speed

|

mm/s

|

60

|

60

|

85

|

60

|

80

|

|

|

Motor power

|

|

KW

|

11

|

15

|

15

|

15

|

22

|

|

Product Description

This machine is suitable for the pressing of bearng parts, bending, pressing and shaping of sheet metal stretching of simple parts,stretching of simple parts.Mainly used in enterprise assembly line.

Processing site

1. Hydraulic power part, manual and electric

2. Mechanical control part;

3. Working cylinder part;

4. Hydraulic power part;

By hydraulic oil pump. The motor is connected to the plunger pump with an elastic coupling

5. Mechanical control part;

It is controlled by distribution box and combination button switch

6. Tubing part: connected by high pressure seamless steel tube

2. Mechanical control part;

3. Working cylinder part;

4. Hydraulic power part;

By hydraulic oil pump. The motor is connected to the plunger pump with an elastic coupling

5. Mechanical control part;

It is controlled by distribution box and combination button switch

6. Tubing part: connected by high pressure seamless steel tube

Company Introduction

Shandong Woda Heavy Industry Machine Tool Co., Ltd.is located in Tengzhou Economic Development Zone, Shandong Province .The company has long been committed to the development of forging machinery and CNC machine tools.

The company is mainly engaged in the development,design,manufacture and technical service of four-column hydraulic press,single-column hydraulic press, gantryhydraulic press,hydraulic stretcher hydraulic cylinder,complete hydraulic system and hydraulicprerss,hydraulic electric controlproduction line .Products are widely used in steel,metallurgy ,light industrial machinery machinery ,chemical machenery ,auto parts ,plastic products and other industries.

Our hydraulic presses are all in accordance with export standards, and we have obtained relevant export certificates and CE certificates International CE certification, Alibaba / China manufacturing network SGS certification.

We go to all kinds of fairs, if you're interested.You can come to China to participate in the exhibition, we will meet here

.

Packing&Shipping

FAQ

Q:How about your machine quality?We are worry about the quality.

A:Woda is a mature brand in China. through our several years research in technology , our design including strcture and detailed sercurity and precision has enhanced greatly, and can match all the CE standard or mor strict standard.Our machines distribute worldwide to about 20 countries where there are metal plate industry.And where there are our machines, there are good reputation and terminal user satisfaction.

Q:Why Choose your company?

A:We can provide customized services according to customer requirements. We also have professional R &D team and fast response sales team. Strictly control each step of QA &QC system processes. We have an after sale service team than can quickly solve any problem you may have in the use.

Q:How to select your machine?

A: you can tell me your specifications ,we can choose the best model for you . we also have some regular model for you to choose.You can also provide the drawings, size , photos of the products, we can design the suitable machine for you according to your requirements. After the machine is finished, you can also provide samples and we will test it for you.

Hot Searches