high quality wood charcoal stick with sawdust, wood chippes, branches, crop stalks, sugarcane residue, coffee husk, paddy

straw, sunflower stalk, cotton stalks, bamboo dust, palm husk, soybeans husk, tea waste, etc.

2. It's equipped with automatic temperature control system and designed to produce high density wood briquette from biomass. the

product of this machine can be used to heat boiler, fireplace, etc for warm in house.

product of this machine can be used to heat boiler, fireplace, etc for warm in house.

3. Perfect working performance:This machine adopts temperature adjusting indicator, it can work steadily at the fixed

temperature and has the feature of rational structure, being easy to operate and maintain.

temperature and has the feature of rational structure, being easy to operate and maintain.

4. Superior quality of the final products:The solid fuel produced by this machine has the feature of being easy to light, and

having high calorific value (over 20% higher than normal wood), little pollution when burning and high density which is

favorable to transportation. This machine can make full use of the remainder of farm and forest.

5. Uniform size: A inner moulding is equipped with the shaping mould, which ensures the shape and final size of the products.

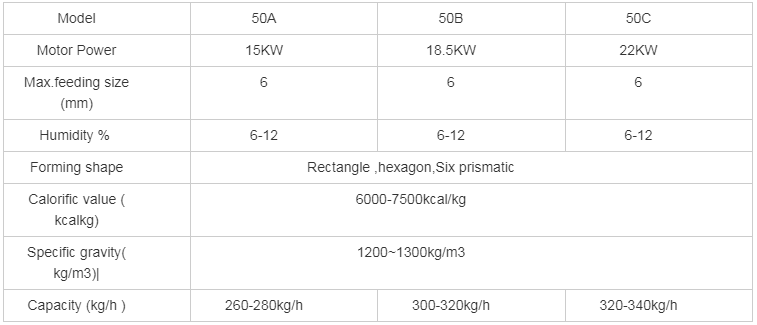

6. Our briquette machine with higher capacity and lower energy consumption.

7. Production moisture is 8-12% ,raw material size below 3-5mm.

8. This series of briquette machine is a new type of wood briquette machine,the finished products are more solid.

having high calorific value (over 20% higher than normal wood), little pollution when burning and high density which is

favorable to transportation. This machine can make full use of the remainder of farm and forest.

5. Uniform size: A inner moulding is equipped with the shaping mould, which ensures the shape and final size of the products.

6. Our briquette machine with higher capacity and lower energy consumption.

7. Production moisture is 8-12% ,raw material size below 3-5mm.

8. This series of briquette machine is a new type of wood briquette machine,the finished products are more solid.

9.This Wood Briquette Machine with automatic temperature control system is designed to produce high density wood briquette stick

from biomass.

from biomass.