High efficiency, high automation and intelligent

World famous brands of configuration

High quality, easy to control and maintenance

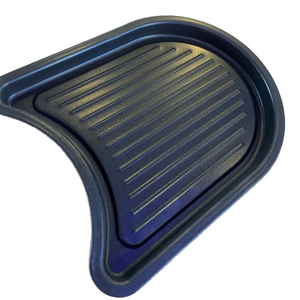

Wide application for all non stick coating