- Product Details

- {{item.text}}

Quick Details

-

Usage:

-

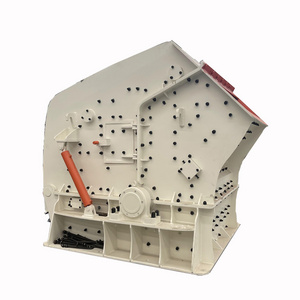

crusher

-

Certification:

-

BV certificate ,ISO2008

Quick Details

-

Weight (KG):

-

3000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

zhili

-

Usage:

-

crusher

-

Certification:

-

BV certificate ,ISO2008

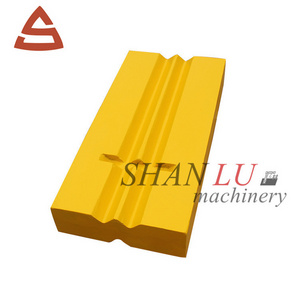

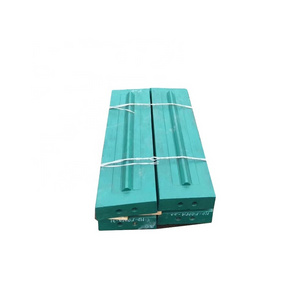

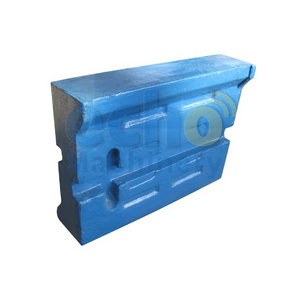

blow bar.

We can provide you with blow bar , also can customize and produce according to your working conditions

Blow bar is the main working spare part for impact crusher , There are many sizes and types of blow bars, generally is high-chromium alloy materials; while large and ultra-large hammers can be made of high manganese steel materials. Our company has a unique process design and advanced production technology especially for large-scale hammers.

The blow bar we have already produced.

|

High manganese steel blow bar

|

Alloyed superior high manganese steel blow bar

|

high manganese steel blow bar

|

high manganese steel blow bar

|

|

High manganese steel blow bar

|

High chromium iron blow bar

|

high manganese steel blow bar

|

High chromium iron blow bar

|

we can provides comprehensive material selection for you

|

Bimetal compisite material

|

|

|

|

|||

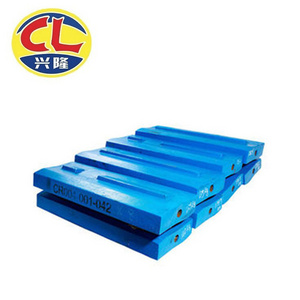

Feature:

This material adopt special technological process to make two material with different property integrate in the same time when they are liquid state.

The bonded area could reach 100% and the impact toughness of the bonded area can get more than 14J/cm2 ,the working part use high Cr casting iron and adopt directional solidification to make Cr7C3 which included in high Cr casting iron perpendicular distribute to the working surface .

The hardness could reach to HRC62-65,and the impact to toughness(AK) is above 30J/cm2 ,It can resist the cutting from AL2O3 and SiO2 perfectly show the high anti-friction property . the hammer handle with high toughness and perfect combined mechanical properties.the material have both high anti-friction and safety property and solve the contradiction between the hardness and toughness effectively ,make the spare parts fit the wicked working condition.

The lifetime of the hammer which made from bimetal composite material is 2-3 times than the lifetime of normal high Mn hammer .Specially suit for the big crusher hammer ,blow bar and liner of big mill .The effect will be prominent in the wicked condition .It is widely used in limestone ,cementclinker,iron,sandstone,gangue ,basalt and so on.

Chemical component.

|

Grade |

Chemical component%

|

|

|

|

|

|

|

|

|||||||

|

|

C

|

Si

|

Mn

|

Cr

|

Mo

|

Ni

|

S

|

P

|

|||||||

|

ZG38CrMnSiMoNiRe

|

0.35~0.45

|

0.4~0.8

|

0.4~1.0

|

0.5~2.0

|

0.20~0.80

|

0.3~2.0

|

≤0.004

|

≤0.004

|

|||||||

Mechanical Property.

|

Grade

|

HRC

Surface Hardness HRC |

Shock absorption energy

KN2/J(unnotched) |

|

ZG38CrMnSiMoNiRe

|

50

|

25

|

|

High Manganese Steel

|

|

|

|

|||

Feature

High manganese steel refers to high alloy steels containing more than 10% manganese. The biggest features of high-manganese steel are:

The greater external compressive stress or impact load, the more conducive to the formation of hardened layer, so the higher the wear resistance of the casting;

With the gradual wear of the hardened layer, new work hardened layers will continue to form under the influence of external compressive stress or impact loads. Therefore, it is suitable for making wearable spare parts that are subject to high impact load and wear for a long time, and is widely used in metallurgy, mining, building materials, railways, electric power, coal and other broken grinding equipment.

Chemical component

|

Grade

|

Chemical component %

|

|

|

|

|

|

||||||

|

|

C

|

Si

|

Mn

|

Cr

|

S

|

P

|

||||||

|

ZG120Mn13

|

1.05~1.35

|

0.3~0.9

|

11~14

|

-

|

≤0.06

|

≤0.04

|

||||||

|

ZG120Mn13Cr2

|

1.05~1.35

|

0.3~0.9

|

11~14

|

1.5~2.5

|

≤0.06

|

≤0.04

|

||||||

|

ZG120Mn17Cr2

|

1.05~1.35

|

0.3~0.9

|

16~19

|

1.5~2.5

|

≤0.06

|

≤0.04

|

||||||

|

1:Allowed to add microscale V,Ti,B and Re etc.

2:We can produce the other grade high manganese steel hammer according to customers' requirments |

|

|

|

|

|

|

||||||

Mechanical Property.

.

|

Grade

|

Stretch property

|

|

|

|

Hardness

HB |

|||

|

|

Yield strength ReH/Mpa

|

tensile strength Rm/Mpa

|

Elongation at cross section%

|

Shock absorption energyKu2J

|

|

|||

|

ZG120Mn13

|

-

|

≥685

|

≥25

|

≥118

|

≤300

|

|||

|

ZG120Mn13Cr2

|

≥390

|

≥735

|

≥20

|

-

|

≤300

|

|||

recommend products.

As one of the professional wear resistant manufacture and merchant, our main products include hammer crusher hammer, impact crusher blow bar, liner plate, grid plate, jaw palte , steel ball and so on. The main application area cover cement, mine, electricity, iron and steel industry etc.

|

shredder machinery hammer

|

Liner plate

|

Blow Bar

|

Jaw Plate

|

|

Our Advantages

|

|

|

|

|||

We are a professional company specialized in :

1. R & D of wear resistant materials and anti-wear technology .

2. The design, manufacture and sales of wear-resistant products .

We have the whole intellectual property of all full-lines products.

Compared with similar products, it has high-effect of anti-friction.

Compared with similar products, good safety performance & long service.

Compared with similar products, its cost performance is obvious.

If you have any questions or would like to know more about our products, please feel free to let us know.

|

Production Process

|

|

|

|

|||

Packaging & Shipping.

1.Industrial packaging :Plastics tube+ carton+ wooden pallets

2.Commercial packing:Plastic bag+ color box+ wooden pallets

3.Transportation: Air/shipping/Railway

4.As the clients'requirement

|

|