- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XKMT

-

Voltage:

-

Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

2000

-

After Warranty Service:

-

Video technical support, Online support, Spare parts,

-

Supply ability:

-

20 Set/Sets per Month

-

Feature:

-

High efficiency and Economical

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Experience:

-

more than 10 years

-

Usage:

-

Sand Moulding Making

-

Type:

-

pneumatic or hydraulic

-

Advantage:

-

Small Energy Consumption

-

Product name:

-

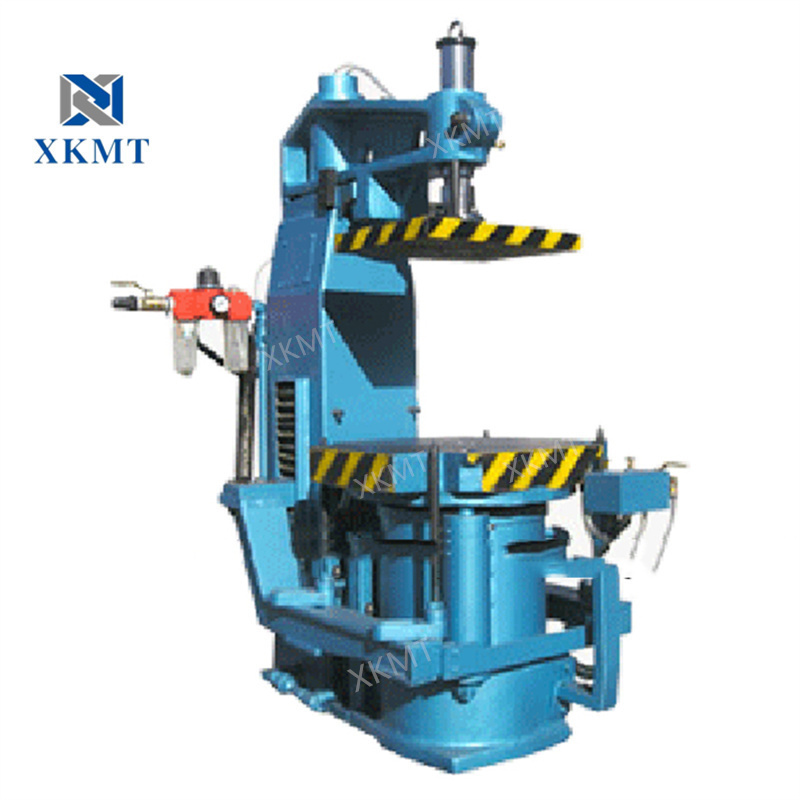

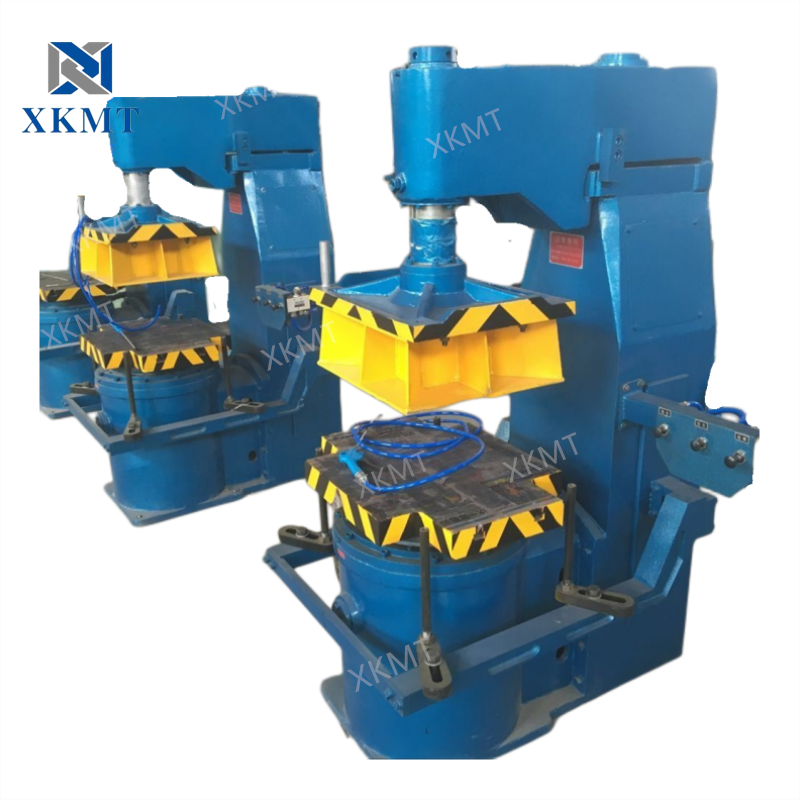

Jolt Squeeze Molding Machine

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

Foundry molding machine

-

Marketing Type:

-

New Product 2022

-

Brand Name:

-

XKMT

-

Voltage:

-

Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

2000

-

After Warranty Service:

-

Video technical support, Online support, Spare parts,

-

Supply ability:

-

20 Set/Sets per Month

-

Feature:

-

High efficiency and Economical

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Experience:

-

more than 10 years

-

Usage:

-

Sand Moulding Making

-

Type:

-

pneumatic or hydraulic

-

Advantage:

-

Small Energy Consumption

-

Product name:

-

Jolt Squeeze Molding Machine

Product Description

Jolt Squeeze Moulding Machine

The molding line is ideal machinery equipment for volume production in foundry moulding workshop, with advantagens of less investment, fast effect, lower workers' labor intensity, improving quality of castings, easy operation and better maintenance .

This kinds of molding line adopts pneumatic jolt squeeze moulding machines( can be equipped with many sets of moulding machines), and casting conveyor transfers casting for pouring and cooling down.

The workers carry moulding flask and sand moulds by pneumatic hoists, core setting, flask dropping, flask assembling, pouring circle tracks, sand shakeout machine, empty flask conveying rollers and flasks.

Product Parameters

|

Item

|

Z143

|

Z144

|

Z145

|

Z146

|

Z148

|

|

Max. size of flask(mm)

|

400*400*100

|

400*500*180

|

450*500*200

|

500*600*200

|

900*800*320

|

|

Size of work table(mm)

|

560*420

|

465*500

|

600*460

|

550*700

|

1000*820

|

|

Jarring Load/Air pressure

(kgf /Mpa)

|

0.55

|

0.6

|

0.6

|

0.6

|

0.6

|

|

Compressive stress(kgf)

|

4000

|

4200

|

6300

|

7000

|

18000

|

|

Compress process(mm)

|

100

|

120

|

160

|

200

|

200

|

|

Distance compacting plate

with worktable(mm)

|

200-370

|

300-400

|

300-450

|

350-450

|

450-600

|

|

Productivity(mould/hour)

|

40-60

|

40-60

|

40-60

|

40-60

|

20-40

|

|

Outline size(L*W*H(mm)

|

955*680

*1282

|

1050*1100

*1410

|

970*774

*1575

|

1200*800

*1684

|

1250*1000

*2000

|

Successful cases

Sand Compaction

of Jolt Squeeze Moulding Machine

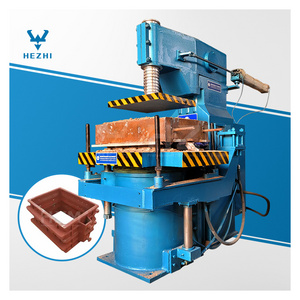

Castings of

Jolt Squeeze Moulding Machine

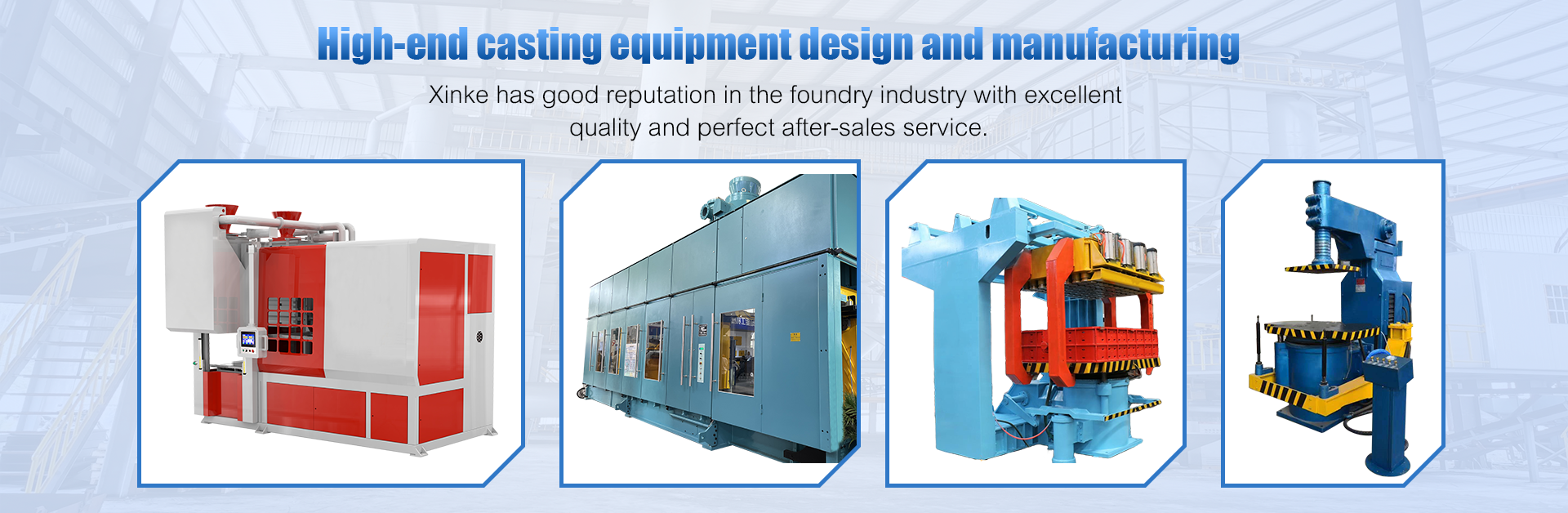

Xinke Production workshop

Hot Searches