- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7kw

-

Place of Origin:

-

ZHEJIANG

-

Brand Name:

-

HAVESINO

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

2050x1700x1400mm; 2200x1050x1600mm

-

Model:

-

N1/N2M/N3M

-

Slitting width:

-

650-1010mm

-

Slitting thickness:

-

0.004mm-0.02 mm

-

Tension control:

-

Automatic control by 4 Servo motor and servo drives

-

Max working speed:

-

N1:250m/min; N2M:300m/min; N3M:400m/min

-

Unwind core type:

-

6 inch shaftless

-

Max unwinding diameter:

-

N1:540mm; N2M & N3M:600mm

-

Max rewinding diameter:

-

N1:110mm; N2M & N3M:140mm

-

Rewinding core type:

-

1 inch & half inch core

Quick Details

-

Applicable Industries:

-

label printing, TTR

-

Application:

-

label printing, Thermal transfer ribbon;Barcode ribbon

-

Voltage:

-

380V/50HZ or CUSTOMIZED

-

Power:

-

7kw

-

Place of Origin:

-

ZHEJIANG

-

Brand Name:

-

HAVESINO

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

2050x1700x1400mm; 2200x1050x1600mm

-

Model:

-

N1/N2M/N3M

-

Slitting width:

-

650-1010mm

-

Slitting thickness:

-

0.004mm-0.02 mm

-

Tension control:

-

Automatic control by 4 Servo motor and servo drives

-

Max working speed:

-

N1:250m/min; N2M:300m/min; N3M:400m/min

-

Unwind core type:

-

6 inch shaftless

-

Max unwinding diameter:

-

N1:540mm; N2M & N3M:600mm

-

Max rewinding diameter:

-

N1:110mm; N2M & N3M:140mm

-

Rewinding core type:

-

1 inch & half inch core

Product Description

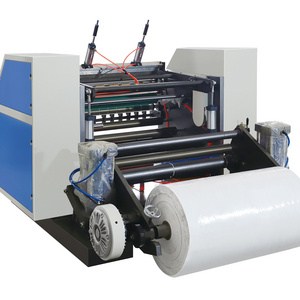

Automatic High Speed Thermal Transfer Ribbon Slitter Barcode Ribbon Ttr Slitting Machine Thermal Transfer Ribbon Cutting Machine

N1/N2M/N3M

Application

Textile Resin Ribbons Slitting Rewinding Machine is professional for slitting: TTR, Thermal transfer ribbon, Barcode Ribbon, Fax Ribbon,Pigment Foil, Hot Stamping Foil, Carbon Ribbon, other film and foil from 4-20um. It is an important machine for ribbon manufacturers and users all over the world.

Textile Resin Ribbons Slitting Rewinding Machine is professional for slitting: TTR, Thermal transfer ribbon, Barcode Ribbon, Fax Ribbon,Pigment Foil, Hot Stamping Foil, Carbon Ribbon, other film and foil from 4-20um. It is an important machine for ribbon manufacturers and users all over the world.

Havesino

Textile Resin Ribbons Slitting Rewinding Machine

works by feeding a large roll of thermal transfer ribbon through the machine and cutting it into smaller rolls of ribbons of the required width. The machine is equipped with magnetic blade holder is much more convenient to adjust to the widths. The machine also has a touch screen, which allows the operator to set the parameters easily.

Magnetic Blade Holder

Easy to adjust the different width quickly

4 Servo Motor Control

Automatic stable tension control by servo motors, long life

Trimming Motors

Rewind the trimming along with machine running

Features

A.High speed(Max .400m/min) and stable working performance.

B.Auto Tension Control.

C.Delta Or Sanyo Servo Motor+SIEMENS PLC.

D.Perfect slitting result.

E.The Fastest and Most Cost Effective TTR Slitting Machine in China.

A.High speed(Max .400m/min) and stable working performance.

B.Auto Tension Control.

C.Delta Or Sanyo Servo Motor+SIEMENS PLC.

D.Perfect slitting result.

E.The Fastest and Most Cost Effective TTR Slitting Machine in China.

Product Paramenters

|

Model

|

TTR Slitting Machine N1/N2M/N3M

|

|

Slitting Width

|

650-1010mm(Optional 1050mm)

|

|

Unwinding Diameter

|

N1:540mm Max; N2M/N3M:600mm Max

|

|

Unwinding Core

|

6 Inch Shaftless

|

|

Rewinding Width

|

20mm Width

|

|

Rewinding Diameter

|

N1:110mm Max; N2M/N3M:140mm Max

|

|

Rewinding Core

|

1 Inch & 0.5 Inch

|

|

Blade Type

|

Magnetic Blade Holder+Razor Blade

|

|

Leader & Trailer Station

|

Semi-automatic(Optional:Fully-automatic)

|

|

Machine Well Thickness

|

N1/N2M: 30mm, N3M:40mm

|

|

Motor + PLC

|

Siemens PLC

N1:Taiwan Delta Servo Motor

N2M/N3M: Japan Sanyo Servo Motor

|

|

Working(slitting) Speed

|

N1:250m/min; N2M:300m/min; N3M:400m/min

|

|

Power Supply

|

380V, 50Hz,3 Phase (can be changed as required)

|

1. 100% test and check before shipment.

2. Detailed instruction handbook.

3. 1 year warranty for key parts.

4. Online installation and operation trainning service.

5. 7*24 hours free technical support for the whole life.

6. Regular on-site routine inspection.

Recommend Products

Hot Searches