Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year(No warranty for wearing parts)

-

Brand Name:

-

OVELL

-

Model Number:

-

A10AAGGA

-

Place of Origin:

-

American

-

Horsepower:

-

none

-

Cable Length:

-

pneumatic

-

Outlet Size:

-

pneumatic

-

Power:

-

pneumatic

-

motor:

-

no

-

Materials:

-

Aluminum housing/Santoprene diaphragm

-

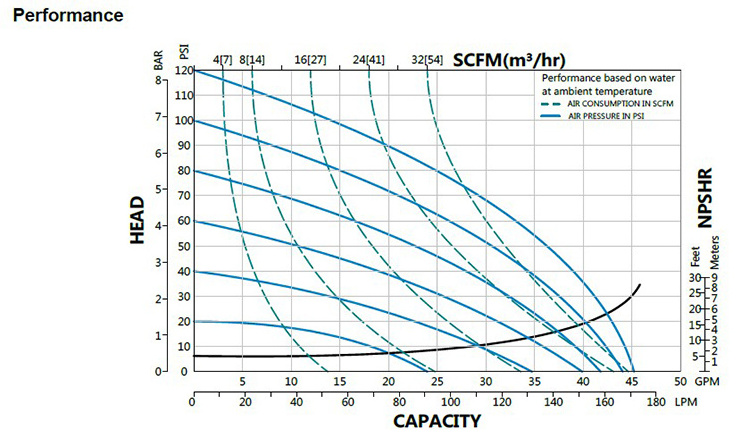

Capacity:

-

0 to 46 gpm (175 lpm)

-

Max Operating Pressure:

-

125 psi (8.6 bar)

-

Port Size:

-

1" BSP

-

Air Inlet:

-

1/4"NPT

-

Air Exhaust:

-

3/8"NPT

-

Max Dry Suction lift:

-

5.5M

-

Max Wet Suction lift:

-

9.5M

-

Solids-Handling:

-

Up to 0 .126" (3.2 mm)

Quick Details

-

Application:

-

Any fluid transportation field, Glue, water-based paint, grease, organic solvent, ceramic glaze,etc

-

Pressure:

-

125 psi (8.6 bar)

-

Voltage:

-

pneumatic

-

Warranty:

-

1 year(No warranty for wearing parts)

-

Brand Name:

-

OVELL

-

Model Number:

-

A10AAGGA

-

Place of Origin:

-

American

-

Horsepower:

-

none

-

Cable Length:

-

pneumatic

-

Outlet Size:

-

pneumatic

-

Power:

-

pneumatic

-

motor:

-

no

-

Materials:

-

Aluminum housing/Santoprene diaphragm

-

Capacity:

-

0 to 46 gpm (175 lpm)

-

Max Operating Pressure:

-

125 psi (8.6 bar)

-

Port Size:

-

1" BSP

-

Air Inlet:

-

1/4"NPT

-

Air Exhaust:

-

3/8"NPT

-

Max Dry Suction lift:

-

5.5M

-

Max Wet Suction lift:

-

9.5M

-

Solids-Handling:

-

Up to 0 .126" (3.2 mm)

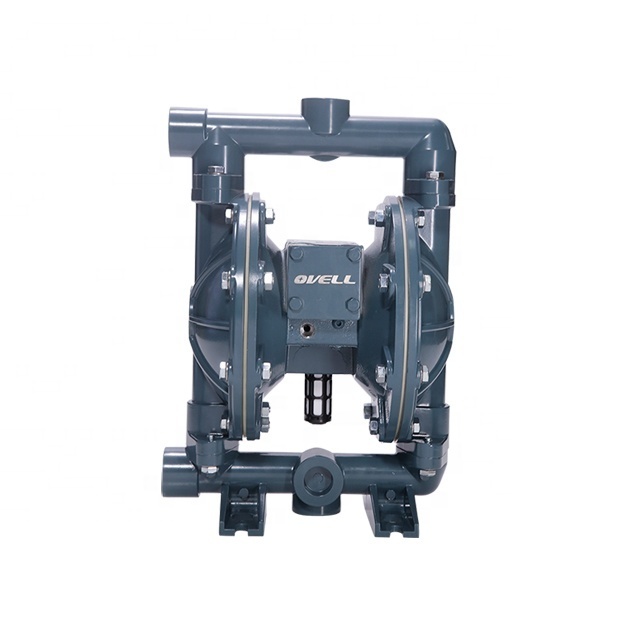

USA OVELL air operated double diaphragm pump/Ceramic slurry and glaze transfer pump/Chemical liquid transfer pump

What is the pneumatical diaphragm pump?

Pneumatic diaphragm pump is a new type of conveying machinery, is the most innovative type of pump currently.

Using compressed air as power source, can be used for all kinds of corrosive liquids.

Pneumatic diaphragm pump has four kinds of materials: engineering plastics, aluminum alloy, cast iron and stainless steel. According to the different liquid, the diaphragm were used with Nitrile rubber, chloroprene rubber, fluorine rubber and ptfe, to meet the different demands of users.

The pump is placed in a variety of special occasions, it has satisfactory results for pumping the medium that conventional pumps can not do.

What are the advantages of pneumatic diaphragm pumps?

1. Pump will not overheat: compressed air as power, in the exhaust is a process of expansion of heat absorption, the temperature of the pneumatic pump is reduced, no harmful gas emissions;

2. The pump will not produce electric spark: pneumatic pumps do not use electricity as power, grounding to prevent the static spark;

3. The pump could delivery liquid containing particles : because of displacement working and the entrance is the valve ball,it can not be easily blocked;

4. The shear force on the material is very low: the outed medium is just as it into the pump, so the smallest stirring for the material, the pump is suitable for delivering unstable substances;

5. The flow rate of the pump can be adjusted, could install the throttle valve at the outlet to regulate flow;

6. The pump have the function of self priming;

7. There is no dangerous without liquid when working;

8. The pump could be used for diving work;

9. The fluid can be transported is very widely, from low viscosity to high viscosity, from corrosive to viscous;

10. No complex control system, no cables, fuses, etc;

11. Small size, light weight, easy to move;

12. The utility model is no need of lubrication so it is convenient to maintenance, will not pollution the working environment because of leakage;

13. The pump can always maintain high efficiency, and will not reduce because of abrasion;

14. One hundred percent of the energy is utilized, when the outlet is closed, the pump would stop automatically;

15. No dynamic seal, easy maintenance to avoid leakage. No dead center at working.

Choosing Ovell pumps is cost-effective and affordable for consumers.

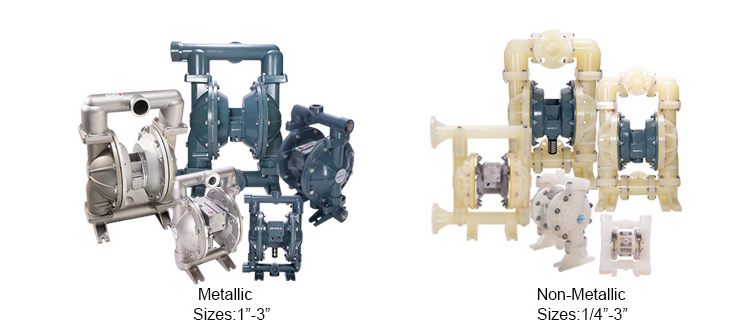

The OVELL Aluminum pneumatical diaphragm pump selection of models:

| Model |

Port Size |

Max Flow Rate |

Max Operating Pressure |

Air Inlet |

Solids-Handing |

| A05AA | 1/2"BSP | 16gpm(62lpm) | 125psi(8.6bar) | 1/4"NPT | 0.098"(2.5mm) |

| A10AA | 1"BSP | 46gpm(175lpm) | 125psi(8.6bar) | 1/4"NPT | 0.126"(3.2mm) |

| A15AA | 1-1/2"BSP | 127gpm(480lpm) | 125psi(8.6bar) | 3/4"NPT | 0.256"(6.5mm) |

| A20SA | 2"BSP | 180gpm(680lpm) | 125psi(8.6bar) | 3/4"NPT | 0.256"(6.5mm) |

| A30SA | 3"BSP | 275gpm(1040lpm) | 125psi(8.6bar) | 3/4"NPT | 0.394"(10mm) |

Note: Models listed and specification in the table are for reference only. please refer to the service manual for complete specifications.

Model:A10AAGGA Specifications of aluminum alloy pump series

| Wetted Material | Aluminun | Max Air Inlet Pressure | 125psi(8.6bar) |

| Diaphragm Material | Santoprene | Max Material Outlet Pressure | 125 p si( 8.6bar) |

| Pump Size | 1" | Max Dry Suction lift | 5.5M |

| Suction Port Size | 1"BSP | Max Wet Suction lift | 9.5M |

| Discharge Port Size | 1"BSP | Max Flow Rate | 46gpm(175lpm) |

| Air Inlet | 1/4"NPT | Max Solid Size (Diameter) | 0.126"(3.2mm) |

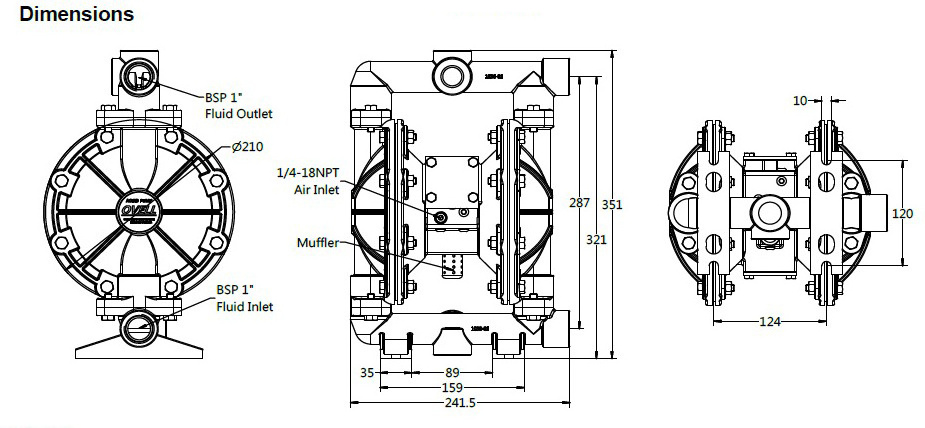

| Air Exhaust | 3/8"NPT | Carton size (mm) | 351*241.5*210 |

Note: Models listed and specification in the table are for reference only. please refer to the service manual for complete specifications.

THE OVELL ADVANTAGES

WITH NEARLY 50 YEARS OF PUMPING EXPERTISE, WE PROVIDE APPLICATION DRIVEN PUMPING SOLUTIONS

The OVELL Advantage

WITH NEARLY 50 YEARS OF PUMPING EXPERTISE, WE PROVIDE APPLICATION DRIVEN PUMPING SOLUTIONS

Product application scene physical picture .Our pumps are designed to give you peace of mind.

OVELL's pneumatic double diaphragm pumps are ideal for the following markets:

| Marine | Applications include oil transfer,fuel transfer, cargo cleanup, deck dewatering, cargo oil transfer,lubricants transfer and much more |

| Pulp & Paper | Applications include bulk transfer,day tank transfer, batching,bleaching, converter / packaging,adhesives / ink and much more |

| Ceramics |

Applications include batching,mixing, casting machines,day tank transfer, mold filling /

cleaning, glaze spray, slip transfer/ recirculation and much more |

|

Pharma / Personal

Care |

Applications include day tank transfer, batching, chemical feed,USA Food and Drugs Administration compliant, personal hygienic/ cosmetics and much more |

| Oil & Gas |

Applications include natural gas fields, service rigs, offshore platform requirements, settling

pond transfer, diesel fuel transfer,spill clean-up, salt water transfer /disposal, flare knockout and much more |

| Chemical | Applications include packaging,drum / tote, processing, injection,mixing and much more |

| Coatings |

Applications include pigment milling, paint filtration, mixing tanks, filling machines, tank

transfer, low shear requirements and much more |

| Wastewater |

Applications include municipal portable utility, neutralize wastewater, waste activated

sludge, return activated sludge,thickened sludge, belt press feed and much more |

Certifications available for pumps in this market include:

| ATEX | Products are Either ECType or Type Examination Certified to Directive 94/9/ EC - Machinery for Use in Potentially Explosive Atmospheres |

| CE | Products are Declared Compliant to Directive 2006/42/EC - Machinery Safety |

| ISO 9001 Quality | Quality System Certified to Ensure Every Product is Made with Care and Quality Control |

| F DA |

USA Food and Drugs Administration Accepted Materials of Construction |

| Underwriters Laboratories | Pumps are UL Listed to UL79 Standard for Use in Fuel Transfer and Pumping Flammable Fluids |

| GOST-R | Certified to Sell Products into Russia |

| EC1935 |

Food Processing F-Series Model Plastic and Elastomer Food Contact Components Meet the

Requirements of EU Regulation 1935/2004/ EC |

| ABS Marine & Offshore | American Bureau of Shipping Type Approval of Metal SANDPIPER Pumps and Tranquilizer Surge Suppressors |