- Product Details

- {{item.text}}

Quick Details

-

Tolerance:

-

±1%

-

Steel Grade:

-

310S, 410, 316Ti, 316L, 321, 430, 304, 304L, 317L

-

Surface Finish:

-

2B

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DZX

-

Model Number:

-

2507

-

Application:

-

industry

-

Product name:

-

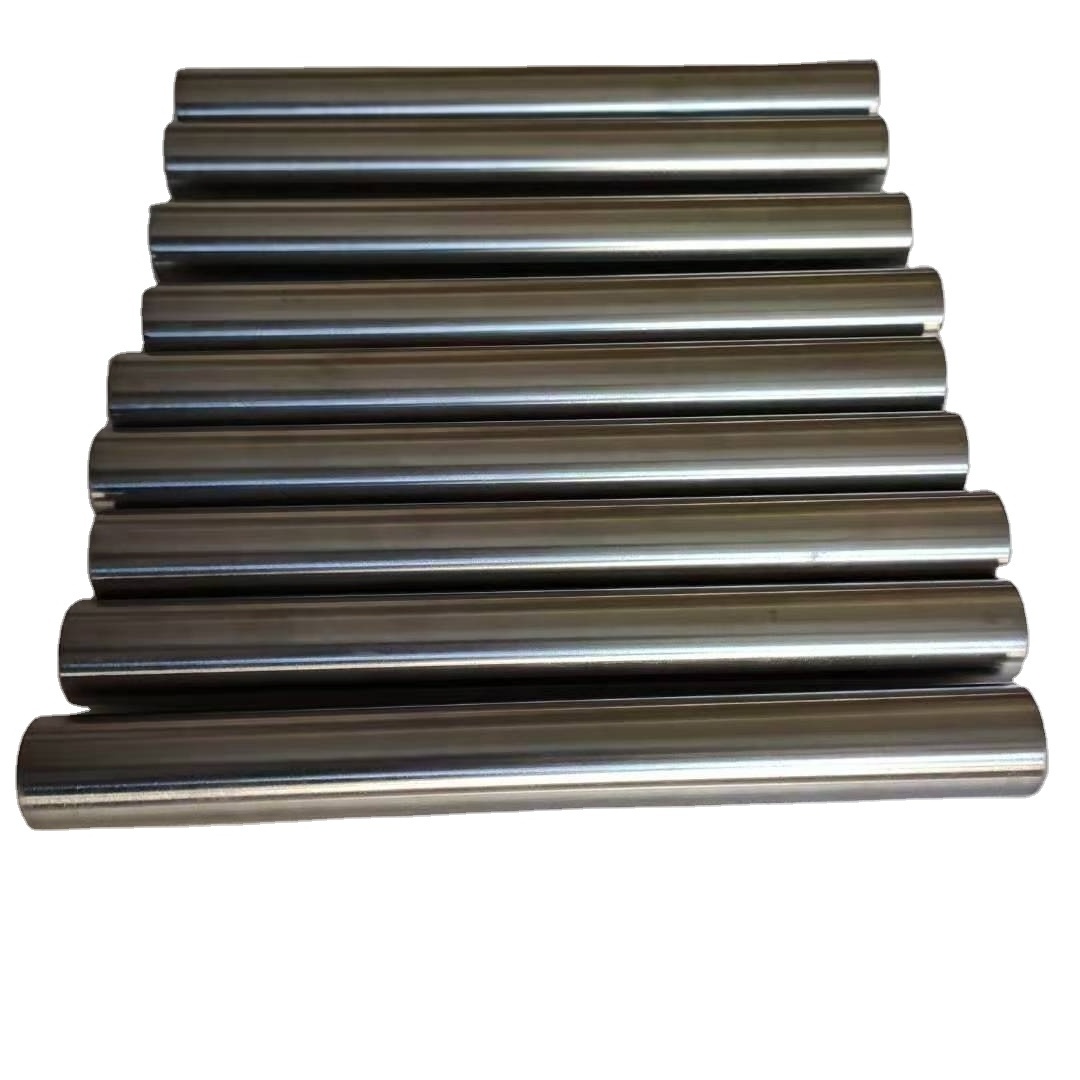

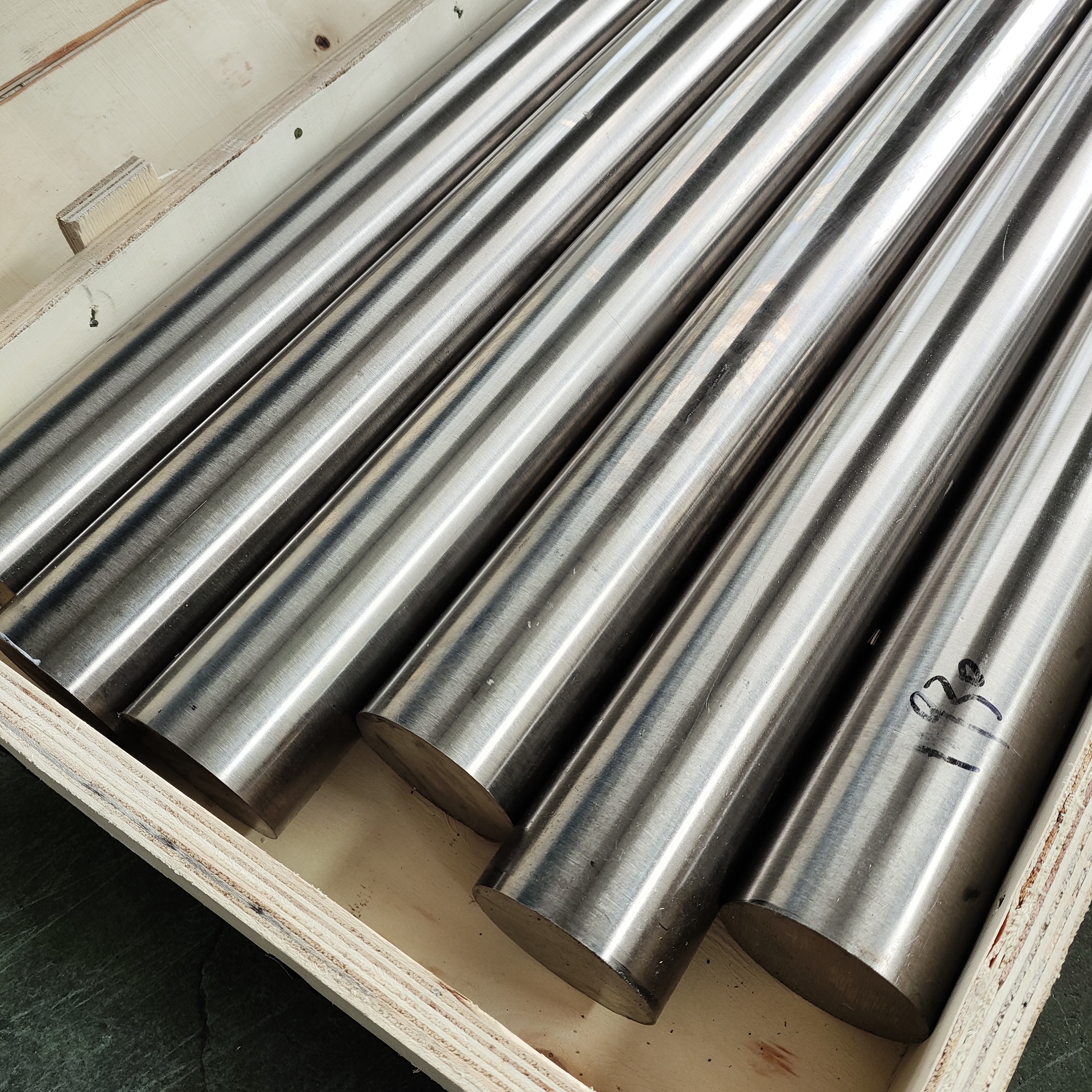

Stainless Steel bar

-

Size:

-

Customized

-

Welding Line Type:

-

Seamless

-

Chemcial composition:

-

Stainless Steel

-

Process Method:

-

Annealing, Polished,cold drawn

-

Condition:

-

Soft Annealed

-

Surface:

-

Annealing

-

Length:

-

Customers' Request

Quick Details

-

Standard:

-

AiSi

-

Grade:

-

300 Series

-

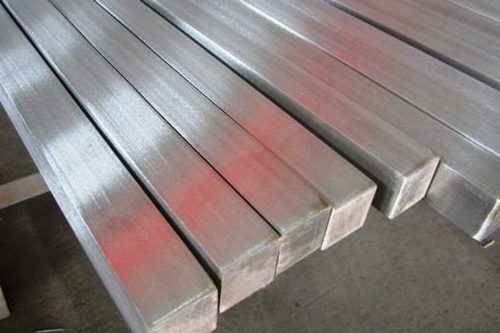

Shape:

-

Square

-

Tolerance:

-

±1%

-

Steel Grade:

-

310S, 410, 316Ti, 316L, 321, 430, 304, 304L, 317L

-

Surface Finish:

-

2B

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DZX

-

Model Number:

-

2507

-

Application:

-

industry

-

Product name:

-

Stainless Steel bar

-

Size:

-

Customized

-

Welding Line Type:

-

Seamless

-

Chemcial composition:

-

Stainless Steel

-

Process Method:

-

Annealing, Polished,cold drawn

-

Condition:

-

Soft Annealed

-

Surface:

-

Annealing

-

Length:

-

Customers' Request

Products Description

Super Duplex Rod UNS 32750 904L 17-4ph 17-7ph 2205 2507 Stainless Steel Round Bars Price Per Kg

Stainless steel rod specifications:

round rod: with a diameter of 1mm ~ 480mm; Square bar: 3*3mm ~ 100*100mm hexagonal bar:S=4mm ~ S=55mm

Material surface:

bright, black leather, grinding, no sand holes, cracks and pitting

Product material: SUS301(1Cr17Ni7), SUS302(1Cr18Ni9), SUS304(0Cr18Ni9), SUS304L(00Cr19Ni10) SUS316(0Cr17Ni12Mo2),SUS316L(00Cr17Ni14Mo2), SUS310S (0Cr25Ni20), SUS321 (1Cr18Ni9Ti), SUS309S(0Cr23Ni13), SUS202 (1Cr18Mn8Ni5N) ), SUS201,(1Cr17Mn6Ni5N), SUS410(1Cr13), SUS420J1(2Cr13), SUS420J2(3Cr13), SUS430(1Cr17), etc

Product material: SUS301(1Cr17Ni7), SUS302(1Cr18Ni9), SUS304(0Cr18Ni9), SUS304L(00Cr19Ni10) SUS316(0Cr17Ni12Mo2),SUS316L(00Cr17Ni14Mo2), SUS310S (0Cr25Ni20), SUS321 (1Cr18Ni9Ti), SUS309S(0Cr23Ni13), SUS202 (1Cr18Mn8Ni5N) ), SUS201,(1Cr17Mn6Ni5N), SUS410(1Cr13), SUS420J1(2Cr13), SUS420J2(3Cr13), SUS430(1Cr17), etc

|

AISI Chemical composition table

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

C

|

Si

|

Mn

|

P

|

S

|

Ni

|

Cr

|

Mo

|

Cu

|

|||||||||

|

304

|

<0.08

|

<1.0

|

<2.0

|

<0.035

|

<0.03

|

8-10

|

17-19

|

-

|

-

|

|||||||||

|

304L

|

<0.03

|

<1.0

|

<2.0

|

<0.04

|

<0.03

|

9-13

|

18-20

|

-

|

-

|

|||||||||

|

304HC

|

<0.06

|

<1.0

|

1.2-1.8

|

<0.035

|

<0.03

|

8-11

|

17-19

|

-

|

2-3

|

|||||||||

|

316

|

<0.08

|

<1.0

|

<2.0

|

<0.04

|

<0.03

|

10-14

|

16-18

|

2-3

|

-

|

|||||||||

|

316L

|

<0.03

|

<1.0

|

<2.0

|

<0.04

|

<0.03

|

12-15

|

16-18

|

2-3

|

-

|

|||||||||

|

310S

|

<0.08

|

<1.5

|

<2.0

|

<0.04

|

<0.03

|

19-22

|

24-26

|

-

|

-

|

|||||||||

|

321

|

<0.08

|

<1.0

|

<2.0

|

<0.045

|

<0.03

|

9-13

|

17-19

|

-

|

-

|

|||||||||

|

301

|

<015

|

<1.0

|

<2.0

|

<0.04

|

<0.03

|

>7

|

16-18

|

-

|

-

|

|||||||||

|

302

|

<0.15

|

<1.0

|

<2.0

|

<0.04

|

<0.03

|

>8

|

17-

|

-

|

-

|

|||||||||

AISI 301

stainless steel (UNS S30100) is a stainless steel that is easier to cold deform and strengthen among traditional

austenitic stainless steels. Its work hardening rate is extremely high, and its tensile strength and yield strength increase

significantly with each increase in the amount of cold work. AISI 301 has good corrosion resistance under atmospheric

conditions,but poor corrosion resistance in reducing media, acids, alkalis, salts and other chemical media, so it is not

recommended for harsh corrosive environments.Type 301 have been extensively used in coining of spoons and forks, other applications include springs, fasteners, clamps, automotive wheel covers, aircraft structural parts, etc.

AISI 304 is a common material in stainless steel, and it is also 18/8 stainless steel in the industry, that is, containing more

than 18% chromium and more than 8% nickel. AISI304 can withstand high temperature of 800 ° C, good processing performance, high toughness, good corrosion resistance, heat resistance, low temperature strength and mechanical properties, good hot workability such as stamping and bending, and no heat treatment hardening. 304 is a versatile stainless steel that is widely used in industrial and furniture decoration industries, as well as in the food and medical industries.

AISI 310 stainless steel is a high chromium nickel austenitic stainless steel with a high carbon content. It has excellent

mechanical properties, high temperature oxidation resistance and heat resistance.Type 310 stainless steel is used in various industrial furnaces, steam boilers and petroleum system parts and thermocouple protection tubes. Examples include fire box sheets,furnace linings, boiler baffles, thermocouple wells, aircraft cabin heaters, and jet engine burner liners.

AISI 310S stainless steel has high oxidation resistance, corrosion resistance and high temperature strength. Compared with other austenitic stainless steel grades, due to the addition of a higher proportion of chromium and nickel, it has better creep strength at high temperatures, and has good oxidation resistance, corrosion resistance, acid and alkali resistance, and high temperature resistance. When 310S stainless steel works at high temperature, the temperature exceeds 800 ℃, it begins to soften, and the allowable stress begins to decrease continuously. AISI 310S stainless steel is widely used in petroleum, electronics,chemical,pharmaceutical, textile, food, machinery, construction, nuclear power, aerospace, military and other industries.

AISI 314 belongs to austenitic stainless steel, high-pressure heat-resistant stainless steel, mainly used in industrial

furnaces,waste incineration plants, heat treatment plants and petrochemical industries, commonly used in furnace equipment, super heater suspensions, enamel furnaces, etc.

AISI 316 is an improved version of 304 with the addition of molybdenum and a slightly higher nickel content to significantly improve the corrosion resistance of stainless steel in most corrosive environments. Molybdenum makes the steel more resistant to pitting and crevice corrosion in chloride environments, seawater and acetic acid vapors. AISI 316 has higher strength and better creep resistance than 304 at elevated temperatures. It also has excellent mechanical properties.316L is a derivative of 18-8 type austenitic stainless steel, with 2 to 3% of Mo added. The Mo content of 316L makes this steel with excellent resistance to pitting corrosion and can be safely used in environments containing Cl- and other halogen ions. Due to its excellent corrosion resistance,it has a wide range of applications in the chemical industry.

AISI 321 stainless steel is Ni-Cr-Ti type austenitic stainless steel, its properties are very similar to 304, but due to the

addition of metal titanium, it has better resistance to grain boundary corrosion and high temperature strength, and has wear resistance. , high temperature resistance, creep resistance, etc., suitable for welding components used at high temperatures.Among them, Ti exists as a stabilizing element, which effectively controls the formation of chromium carbide. 321 stainless steel has good anti-corrosion performance in organic and inorganic acids of different concentrations and temperatures, especially in oxidizing media, and is mostly used in the manufacture of linings and conveying pipes for wear-resistant acid containers and wear-resistant equipment.

austenitic stainless steels. Its work hardening rate is extremely high, and its tensile strength and yield strength increase

significantly with each increase in the amount of cold work. AISI 301 has good corrosion resistance under atmospheric

conditions,but poor corrosion resistance in reducing media, acids, alkalis, salts and other chemical media, so it is not

recommended for harsh corrosive environments.Type 301 have been extensively used in coining of spoons and forks, other applications include springs, fasteners, clamps, automotive wheel covers, aircraft structural parts, etc.

AISI 304 is a common material in stainless steel, and it is also 18/8 stainless steel in the industry, that is, containing more

than 18% chromium and more than 8% nickel. AISI304 can withstand high temperature of 800 ° C, good processing performance, high toughness, good corrosion resistance, heat resistance, low temperature strength and mechanical properties, good hot workability such as stamping and bending, and no heat treatment hardening. 304 is a versatile stainless steel that is widely used in industrial and furniture decoration industries, as well as in the food and medical industries.

AISI 310 stainless steel is a high chromium nickel austenitic stainless steel with a high carbon content. It has excellent

mechanical properties, high temperature oxidation resistance and heat resistance.Type 310 stainless steel is used in various industrial furnaces, steam boilers and petroleum system parts and thermocouple protection tubes. Examples include fire box sheets,furnace linings, boiler baffles, thermocouple wells, aircraft cabin heaters, and jet engine burner liners.

AISI 310S stainless steel has high oxidation resistance, corrosion resistance and high temperature strength. Compared with other austenitic stainless steel grades, due to the addition of a higher proportion of chromium and nickel, it has better creep strength at high temperatures, and has good oxidation resistance, corrosion resistance, acid and alkali resistance, and high temperature resistance. When 310S stainless steel works at high temperature, the temperature exceeds 800 ℃, it begins to soften, and the allowable stress begins to decrease continuously. AISI 310S stainless steel is widely used in petroleum, electronics,chemical,pharmaceutical, textile, food, machinery, construction, nuclear power, aerospace, military and other industries.

AISI 314 belongs to austenitic stainless steel, high-pressure heat-resistant stainless steel, mainly used in industrial

furnaces,waste incineration plants, heat treatment plants and petrochemical industries, commonly used in furnace equipment, super heater suspensions, enamel furnaces, etc.

AISI 316 is an improved version of 304 with the addition of molybdenum and a slightly higher nickel content to significantly improve the corrosion resistance of stainless steel in most corrosive environments. Molybdenum makes the steel more resistant to pitting and crevice corrosion in chloride environments, seawater and acetic acid vapors. AISI 316 has higher strength and better creep resistance than 304 at elevated temperatures. It also has excellent mechanical properties.316L is a derivative of 18-8 type austenitic stainless steel, with 2 to 3% of Mo added. The Mo content of 316L makes this steel with excellent resistance to pitting corrosion and can be safely used in environments containing Cl- and other halogen ions. Due to its excellent corrosion resistance,it has a wide range of applications in the chemical industry.

AISI 321 stainless steel is Ni-Cr-Ti type austenitic stainless steel, its properties are very similar to 304, but due to the

addition of metal titanium, it has better resistance to grain boundary corrosion and high temperature strength, and has wear resistance. , high temperature resistance, creep resistance, etc., suitable for welding components used at high temperatures.Among them, Ti exists as a stabilizing element, which effectively controls the formation of chromium carbide. 321 stainless steel has good anti-corrosion performance in organic and inorganic acids of different concentrations and temperatures, especially in oxidizing media, and is mostly used in the manufacture of linings and conveying pipes for wear-resistant acid containers and wear-resistant equipment.

About Us

JIANGSU DZX TECHNOLOGY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire,strip, ribbon, bar, tube, plate.

Customized service

FAQ

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00) We have public holiday during May.1-3,

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Mobile/whatsapp/skype/wechat:+8618951210953

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.

Hot Searches