- Product Details

- {{item.text}}

Quick Details

-

Bending Precision (Deg):

-

1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PRIMAPRESS

-

Year:

-

2022

-

Power (kW):

-

7.5

-

Weight (KG):

-

2500

-

CNC or Not:

-

CNC

-

Certification:

-

CE ISO

-

Product name:

-

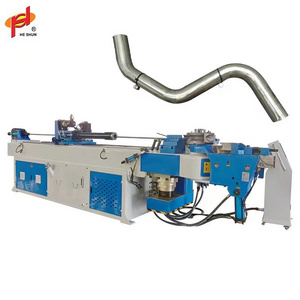

Pipe Bending Machine tube Bending Machine 3 Axis

-

Application:

-

Pipe Bending Machine

-

After Warranty Service:

-

Video technical support

Quick Details

-

Machine Type:

-

pipe bending machine, Pipe Bending Machine

-

Bending Radius (mm):

-

150 - 180

-

Max. Bending Angle (Deg):

-

180

-

Bending Precision (Deg):

-

1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PRIMAPRESS

-

Year:

-

2022

-

Power (kW):

-

7.5

-

Weight (KG):

-

2500

-

CNC or Not:

-

CNC

-

Certification:

-

CE ISO

-

Product name:

-

Pipe Bending Machine tube Bending Machine 3 Axis

-

Application:

-

Pipe Bending Machine

-

After Warranty Service:

-

Video technical support

Pipe Bending Machine tube Bending Machine 3 Axis Cnc Pipe Bending Machine

Videos in Youtube:

| https://youtu.be/Uq-Wv_Z6wq8 |

Prima is first brand in pipe punching air From China.

Main Features:

1, Process introduction and advantages of punching and drilling:

1. Automatic feeding and automatic punching after artificial feeding

2, precision of punching precision, increase the rate of finished products

3. The labor intensity of the workers is low, the operation is simple and the labor is saved.

4. High safety, unique structural design of machine and die safety, to ensure the safety of workers and reduce industrial accidents

5. Program adjustment of punching spacing

6, easy maintenance, stable and mature standard parts system, convenient and easy maintenance, reduce maintenance costs. Campus is an automatic process, continuous forward clamping to send plates, to achieve the desired desired results.

Punching and drilling efficiency

1. single flush a tube, which can basically meet the punching at any position above a tube.

2. punching speed: 40-60 times per min..

3. hole distance precision: + 0.15

4. the length of the punching hole of the largest workpiece: 6M

The 5. operation interface is simple and easy to learn, the idiot operation, the punching hole can not be equal distance punching, but also can equidistance punching.

6. feeding mode: after the automatic feeding of the workpiece by hydraulic clamping, the material is sent out automatically according to the distance of the hole. The feeding mode adopts the high precision servo motor to control the feed automatically.