- Product Details

- {{item.text}}

Quick Details

-

Span:

-

10-40m

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SANTO

-

Weight (KG):

-

3500 kg

-

Product Name:

-

Overhead Crane

-

Application:

-

Molten metal ladle lifting & handling

-

Lifting mechanism:

-

Electric Winch Trolley

-

Control method:

-

Cabin Control

-

Type:

-

QDY/YZ/YZS Teeming Ladle Charging Tundish Crane

-

Power Source:

-

3 Phase 380V 50hz/Custmized

-

Main electrical parts:

-

Request

-

Material:

-

Q235B

-

Work Class:

-

A6, A7, A8

-

Certification:

-

ISO, CE

Quick Details

-

Max. Lifting Height:

-

30m

-

Rated Lifting Moment:

-

As per load capacity

-

Max. Lifting Load:

-

320t

-

Span:

-

10-40m

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SANTO

-

Weight (KG):

-

3500 kg

-

Product Name:

-

Overhead Crane

-

Application:

-

Molten metal ladle lifting & handling

-

Lifting mechanism:

-

Electric Winch Trolley

-

Control method:

-

Cabin Control

-

Type:

-

QDY/YZ/YZS Teeming Ladle Charging Tundish Crane

-

Power Source:

-

3 Phase 380V 50hz/Custmized

-

Main electrical parts:

-

Request

-

Material:

-

Q235B

-

Work Class:

-

A6, A7, A8

-

Certification:

-

ISO, CE

Plc Control Avaliable Heat Casting Overhead Crane

| [ Foudry Crane / Cast Crane / Ladle Crane ] |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

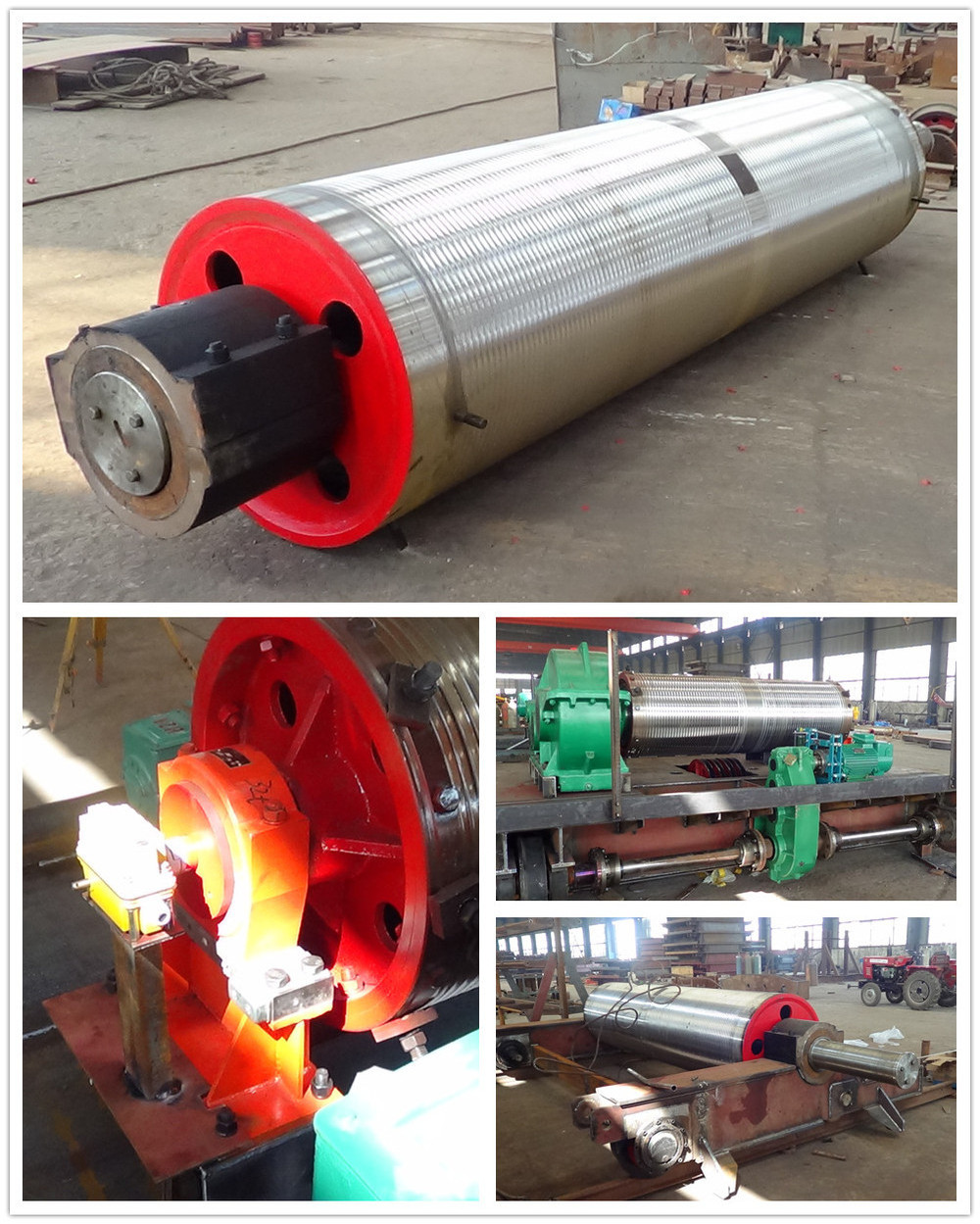

A metallurgical overhead crane is specially designed for metallurgy and metal smelting plants. It travels along the rail track of the factory building, and the winch hoist does cross traveling on the crane girders, usually lifting steel products or molten metals with its hooks. It can be also a single girder overhead crane with a metallurgy heat resistance hoist.

Metallurgical cranes are usually working in the temperature of -10°C to +50°C, and the relative humidity <50° at a temperature of 40°C. The radiation heat of the molten metal lifted by forging hooks or laminated hooks does not exceed 300°C. For high frequency and heavy load lifting, the working duty can reach A7 and A8. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

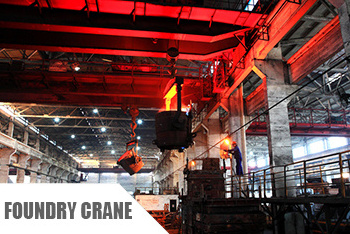

Foundry crane is the main equipment during the steelmaking process. The crane is applicable in steelmaking workshop to transfer liquid steel or metal under the high temperature, dusty working environment. With the develpment of steel industry, the foundry crane need to work more frenquently. So the foundry crane must be safety and reliable, and even when some parts demaged, Our crane can keep the ladle not falling or rollover. The framework of our crane is simple, and can be maintained very quickly in order to ensure the steelmaking production continuously. Now we can supply foundry crane capacity up to 630 ton. Also according to customer's requirement we can provide special design. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Double Girder Foundry Crane | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Four Girder Foundry Crane | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

In order to make a very quick offer and saving your waiting time, It's better to fill the information below. Copy and send us the information together with the enquiry.

|

{Tips: 5 ton, 10 ton, 16 ton, 20 ton, 30 ton, 40 ton, 50 ton up to 550 ton} | ||||||||||||||||||||||||

| {Tips: 6m ~40m} | |||||||||||||||||||||||||

| {Tips: 380V, 50Hz, AC, 3-phase or please note} | |||||||||||||||||||||||||

| {Tips: A5, A3, If you don't know, please fill the follow} | |||||||||||||||||||||||||

| {Tips: Remote control, cabin control or pendent control } | |||||||||||||||||||||||||

| {Tips: Single speed, double speed, or stepless speed} | |||||||||||||||||||||||||

| {Tips: Single speed or stepless speed} | |||||||||||||||||||||||||

| {Tips: If yes, please note the Long travel length} | |||||||||||||||||||||||||

| {Tips: If yes, please note the Long travel length} | |||||||||||||||||||||||||

| {Tips: We quote CIF price need the port. FOB price please note FOB} |

If your workshop roof is very low, Its better to send us a drawing, a sketch or show us datas and then our Engineer can work out a full suitable solution just for yours.

Looking forward your kindly inquiry and hope to help your strong business in near future!