- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

500 KG

-

Product name:

-

Skin Packing Machine

-

product name:

-

tray sealing machine

-

Material:

-

304 Stainless Steel

-

Packing speed:

-

adjustable

-

CE:

-

Supply

-

Capacity:

-

2~5 Times/min

-

Suitable for:

-

PP PE PET Plastic Film

-

Operate:

-

Easily

-

Advantage:

-

High Efficiency Vaccum Sealer Vacuum Packing

-

mold:

-

by customer requirement

Quick Details

-

Packaging Type:

-

Cartons, Bottles, Barrel, Stand-up Pouch, Bags, Film, Foil, Belt, Pouch, case

-

Packaging Material:

-

Plastic, Paper, Metal, Glass

-

Voltage:

-

110 220 240 380 415 440 V

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

500 KG

-

Product name:

-

Skin Packing Machine

-

product name:

-

tray sealing machine

-

Material:

-

304 Stainless Steel

-

Packing speed:

-

adjustable

-

CE:

-

Supply

-

Capacity:

-

2~5 Times/min

-

Suitable for:

-

PP PE PET Plastic Film

-

Operate:

-

Easily

-

Advantage:

-

High Efficiency Vaccum Sealer Vacuum Packing

-

mold:

-

by customer requirement

5 Years guarantee

Modified Atmosphere Packaging Machine Sandwich Tray Vacuum Nitrogen Packing hot vacuum food tray sealing machine for food price

tray box packing machine suit for all kinds of cup and box tray and we can supply film too

we focus on after sales service

1. we take many spare parts with machine

2. 2 years all free spare sparts

3. 3-5 years only get cost fee

2. 2 years all free spare sparts

3. 3-5 years only get cost fee

4. 2 hours feedback customer problem

5 . for wholly life guarantee

5 . for wholly life guarantee

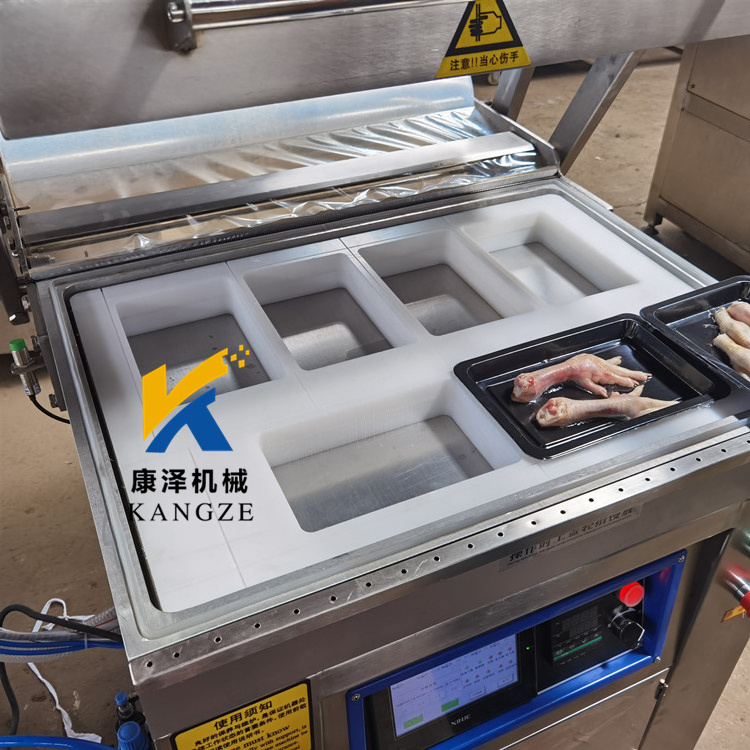

product introduction

tray sealing machine

This machine adopts

the combined control of machine, electricity and gas. The programmable controller and PLC cooperate with the control screen to

realize the man-machine interface dialogue. Each part of the action and control parameters can be set and modified through the

PLC. Convenient operation and control. Reliable. Low failure rate. The use of aluminum alloy and acid-resistant aluminum molds has

the functions of non-deformation and corrosion resistance. The packaging process is highly automated and the packaging yield is

high. The main parts of the whole machine are made of 304 stainless steel to ensure food hygiene. The shape of the mold can be

configured according to the shape of the packaging box selected by the user, with a wide range of applications. Nitrogen or mixed

gas can be filled according to customer requirements (gas mixer is optional) to ensure food packaging requirements.

Four, performance description

(1) This machine is controlled by a programmable controller PLC, and the parameters can be set according to requirements

(2) Vacuum packaging can be used alone, and the vacuum degree is adjustable.

(3) Sealed packaging can be used alone, with adjustable pressure.

(4) Vacuum-inflation-sealing packaging can be realized, and the amount of inflation can be adjusted.

(5) The machine is equipped with a vacuum chamber, which has a high degree of vacuum. The gas exchange is completed in the

ultimate vacuum. The gas replacement rate is above 99.9%, and there is almost no air residue.

(6) With photoelectric control, the light film and color film can be used on the same machine.

the combined control of machine, electricity and gas. The programmable controller and PLC cooperate with the control screen to

realize the man-machine interface dialogue. Each part of the action and control parameters can be set and modified through the

PLC. Convenient operation and control. Reliable. Low failure rate. The use of aluminum alloy and acid-resistant aluminum molds has

the functions of non-deformation and corrosion resistance. The packaging process is highly automated and the packaging yield is

high. The main parts of the whole machine are made of 304 stainless steel to ensure food hygiene. The shape of the mold can be

configured according to the shape of the packaging box selected by the user, with a wide range of applications. Nitrogen or mixed

gas can be filled according to customer requirements (gas mixer is optional) to ensure food packaging requirements.

Four, performance description

(1) This machine is controlled by a programmable controller PLC, and the parameters can be set according to requirements

(2) Vacuum packaging can be used alone, and the vacuum degree is adjustable.

(3) Sealed packaging can be used alone, with adjustable pressure.

(4) Vacuum-inflation-sealing packaging can be realized, and the amount of inflation can be adjusted.

(5) The machine is equipped with a vacuum chamber, which has a high degree of vacuum. The gas exchange is completed in the

ultimate vacuum. The gas replacement rate is above 99.9%, and there is almost no air residue.

(6) With photoelectric control, the light film and color film can be used on the same machine.

skin packing machine

Body packaging machines are all 304 stainless

steel production, corrosion resistance, no rust, durable, stable performance, simple operation, convenient maintenance. At the

same time, it can quickly customize various non-standard machine types of vacuum according to user special requirements. With the

advantages of advanced technical experience of the Japanese control line, it has the advantages of waterproof, moisture-proof, low

failure rate, long service life, so that the equipment is convenient for cleaning, vacuum filling packaging machine adopts

international standard food 304 stainless steel The plate, the strength is high, not easy to break, 304 stainless steel is

corrosion resistance, ductile stainless steel.

steel production, corrosion resistance, no rust, durable, stable performance, simple operation, convenient maintenance. At the

same time, it can quickly customize various non-standard machine types of vacuum according to user special requirements. With the

advantages of advanced technical experience of the Japanese control line, it has the advantages of waterproof, moisture-proof, low

failure rate, long service life, so that the equipment is convenient for cleaning, vacuum filling packaging machine adopts

international standard food 304 stainless steel The plate, the strength is high, not easy to break, 304 stainless steel is

corrosion resistance, ductile stainless steel.

skin packing machine small

The bodied vacuum packaging machine is to heat

the bodied film, and then cover the product and the bottom plate, while enabling vacuum suction below the bottom plate, the bodied

film is shaped in shape and pasted on the bottom plate (high barrier bodies). After the packaging, the product is tightly wrapped

between the pneumatic film and the bottom plate, the three-dimensional strong, the visual display is good, the sealing is good. It

can effectively moisture, dust, earthquake

the bodied film, and then cover the product and the bottom plate, while enabling vacuum suction below the bottom plate, the bodied

film is shaped in shape and pasted on the bottom plate (high barrier bodies). After the packaging, the product is tightly wrapped

between the pneumatic film and the bottom plate, the three-dimensional strong, the visual display is good, the sealing is good. It

can effectively moisture, dust, earthquake

Product Paramenters

skin sealing machine small

machine dimension :

720*570*520 mm

chamber dimension :

430*350*50 mm

power :1.7kw

220v 50hz single phase

and can design mold and voltage by customer requirement

skin sealing machine

Dimension : 940×860×1000mm Supply electric: 380 220 V/50 60HZ

Vacuum chamber size : 700×500×135mm Wholly weight : 280kg

Production capacity : 2-5times/ minutes Power : 5.5Kw

suitable range

Details Images

workshop and warehouse logistic

Hot Searches