Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customer Standard

-

Dimension(L*W*H):

-

5000*1200*1800MM

-

Weight:

-

6000

-

Screw Speed (rpm):

-

73 - 75 rpm

-

Pelletizing type:

-

Strand Cutting

-

Motor:

-

SIEMENS Brand

-

SCREW MATERIAL:

-

38CrMoAl

-

Advantage:

-

Long Service Life

-

After-sales Service Provided:

-

Free spare parts

-

Certification:

-

CE

-

Marketing Type:

-

New Product

Quick Details

-

Output (kg/h):

-

100 - 800 kg/h

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

KEHAO

-

Voltage:

-

Customer Standard

-

Dimension(L*W*H):

-

5000*1200*1800MM

-

Weight:

-

6000

-

Screw Speed (rpm):

-

73 - 75 rpm

-

Pelletizing type:

-

Strand Cutting

-

Motor:

-

SIEMENS Brand

-

SCREW MATERIAL:

-

38CrMoAl

-

Advantage:

-

Long Service Life

-

After-sales Service Provided:

-

Free spare parts

-

Certification:

-

CE

-

Marketing Type:

-

New Product

Competitive Price Plastic Pellets Making Machine Granulator PET Granulating PVC PP PE Recycling Machine

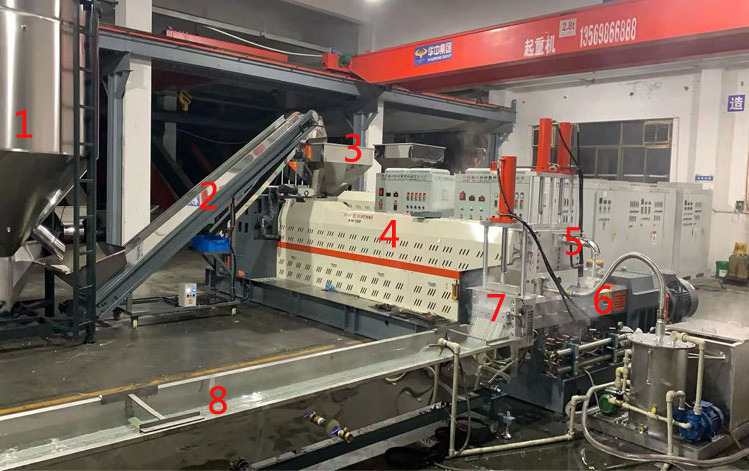

1.The blender is used to mix and heat wet plastics and additives.

2.The self-designed frequency feeder can separate magnetic impurities in the plastic.

3.Different feeders are designed for the characteristics of plastics, which can better protect the screw and feed evenly.

4.The raw material is 38CrMoAl, different plastic different screw.

5.Double station can change the net without stopping machine.

6.The second plasticization can better improve the quality and output of plastics.

7.The second filter to get better quality.

8.Use different length tanks for cooling plastic noodles.(Water can be recycled by water tower )

9.The pellets cutting machine with frequency(Siemens Motor,very low noise).

10.The high-power fan blows the particles to the storage bucket.

11.Store particles to reduce labor consumption.

Q1:Do you support overseas after-sales service?

A:Some countries support overseas after-sales service, the specific situation is negotiated.

Q2:how long is the warranty?

A:Within 1 year from date of the factory, if parts failure or damage

(because of the quality problem ,except wearing parts)

Q3:Do you provide technical support?

A:We provide lifelong technical support .Help each customer solve problems is our original intention.

Q4:The factors of plastic granulator line price?

1. Voltage and frequency in your country

2. The raw materials you are going to deal with, ABS PP PE PVC PET?

3. The output per day

4. The cleanliness of the raw materials, whether it needs to be cleaned (it is best to provide raw material pictures)

Q5:What is your payment term ?

A: 30% T/T in advance ,70% balance before shipment or Negotiable

If you have another question, please feel free to contact us as below