- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MOVMES

-

Fork Length:

-

1200mm

-

Fork Width:

-

1260mm

-

Overall Dimensions:

-

2950x1260x2635mm

-

Weight (KG):

-

6370 kg

-

Name:

-

Narrow aisle reach truck

-

Rated capacity/rated load:

-

1500kg

-

Load centre distance:

-

600mm

-

Wheelbase:

-

1595mm

-

Tyre size, front:

-

dia 125x82 mm

-

Tyre size, rear:

-

dia 343x140 mm

-

Tread, front:

-

1312 mm

-

Turning radius:

-

1880 mm

-

Travel speed, laden/unladen:

-

8/8.5 km/h

-

Fork dimensions:

-

45/125/1200 mm

Quick Details

-

Min. Lifting Height:

-

2635mm

-

Warranty:

-

1 Year

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MOVMES

-

Fork Length:

-

1200mm

-

Fork Width:

-

1260mm

-

Overall Dimensions:

-

2950x1260x2635mm

-

Weight (KG):

-

6370 kg

-

Name:

-

Narrow aisle reach truck

-

Rated capacity/rated load:

-

1500kg

-

Load centre distance:

-

600mm

-

Wheelbase:

-

1595mm

-

Tyre size, front:

-

dia 125x82 mm

-

Tyre size, rear:

-

dia 343x140 mm

-

Tread, front:

-

1312 mm

-

Turning radius:

-

1880 mm

-

Travel speed, laden/unladen:

-

8/8.5 km/h

-

Fork dimensions:

-

45/125/1200 mm

Products Description

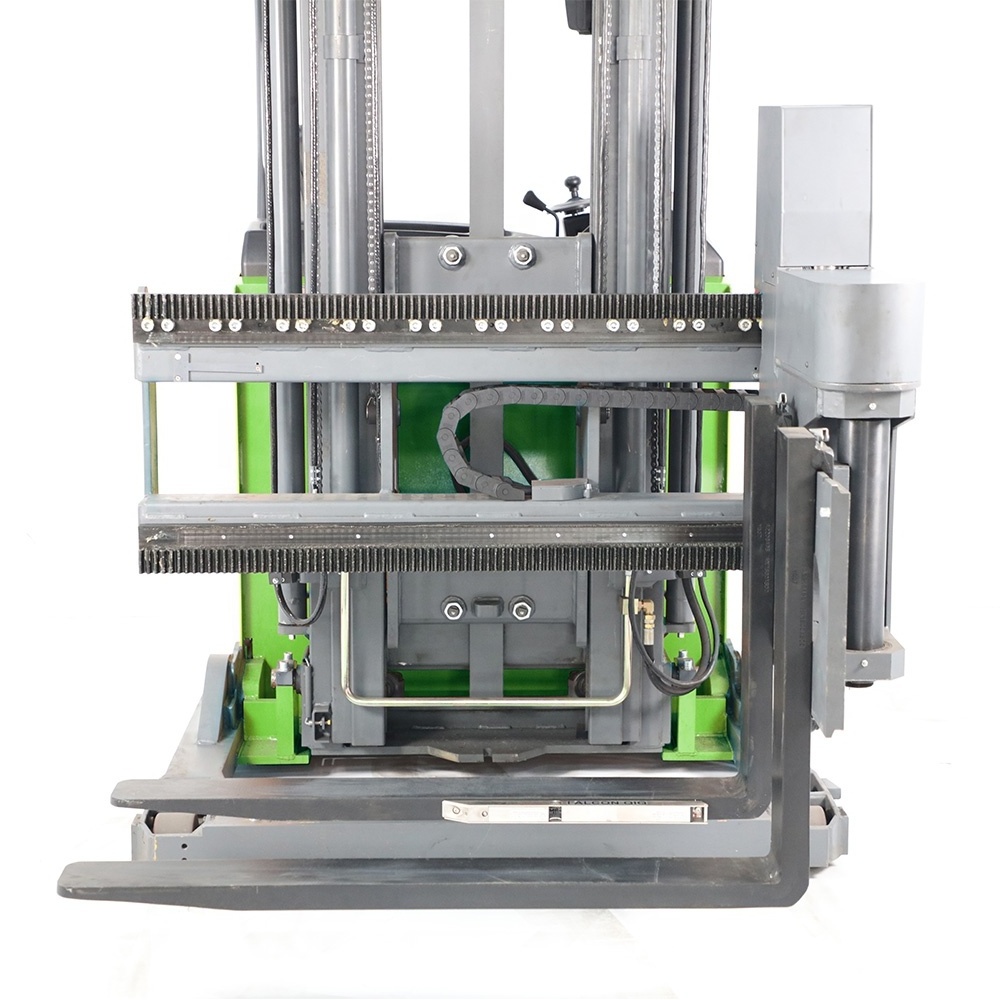

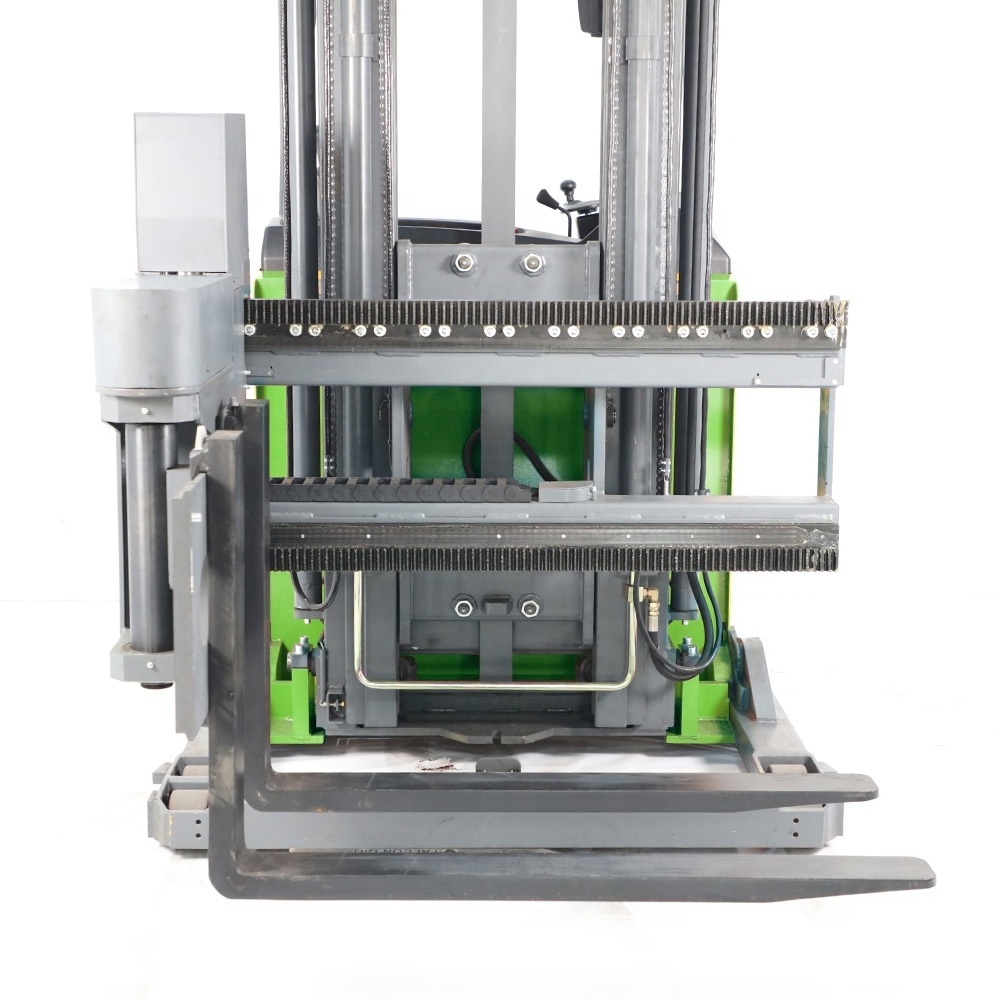

Multi directional Electric narrow aisle reach truck side loader forklift electric lift stacker

Standard Configuration

Specification

|

1.2

|

Manufacturer's type designition

|

|

OPD15Z

|

|

1.3

|

Drive: electric (battery type, mains, ...), diesel, petrol, fuel gas

|

|

Electric

|

|

1.4

|

Operator type: hand, pedestrian, standing, seated, order-picker

|

|

Seated

|

|

1.5

|

Rated capacity/rated load

|

Q (kg)

|

1500

|

|

1.6

|

Load centre distance

|

c (mm)

|

600

|

|

1.8

|

Load distance, centre of drive axle to fork

|

x (mm)

|

21

|

|

1.9

|

Wheelbase

|

y (mm)

|

1595

|

|

3.1

|

Tyres: solid rubber, superelastic, pneumatic, polyurethane

|

|

PU

|

|

3.2

|

Tyre size, front

|

|

125x82

|

|

3.3

|

Tyre size, rear

|

|

343x140

|

|

3.5

|

Wheels, number front/rear (× = driven wheels)

|

|

4+1x

|

|

3.6

|

Tread, front

|

b10 (mm)

|

1312

|

|

4.2

|

Height, mast lowered

|

h1 (mm)

|

2635/2800/2965/3140/3305/3470/3630

|

|

4.3

|

Free lift

|

h2 (mm)

|

1310/1475/1640/1805/1970/2135/2300

|

|

4.4

|

Lift

|

h3 (mm)

|

4500/5000/5500/6000/6500/7000/7500

|

|

4.5

|

Height, mast extended

|

h4 (mm)

|

5770/6270/6770/7270/7770/8270/8770

|

|

4.7

|

Height of overhead guard (cabin)

|

h6 (mm)

|

2212

|

|

4.8

|

Seat height relating to SIP/stand height

|

h7 (mm)

|

1100

|

|

4.1

|

Height of wheel arms

|

h8 (mm)

|

130

|

|

4.19

|

Overall length

|

l1 (mm)

|

2950

|

|

4.2

|

Length to face of forks

|

l2 (mm)

|

2670

|

|

4.21

|

Overall width

|

b1/b2 (mm)

|

1260/1534

|

|

4.22

|

Fork dimensions DIN ISO 2331

|

s / e / l (mm)

|

45/125/1200

|

|

4.23

|

Fork carriage ISO 2328, class/type A, B

|

|

2/A

|

|

4.24

|

Fork-carriage width

|

b3 (mm)

|

880

|

|

4.27

|

Width across guide rolls

|

b6 (mm)

|

1550

|

|

4.29

|

Reach, lateral

|

b7 (mm)

|

1290

|

|

4.3

|

Reach, lateral from vehicle centreline

|

b8 (mm)

|

470

|

|

4.32

|

Ground clearance, centre of wheelbase

|

m2 (mm)

|

50

|

|

4.34.1

|

Aisle width for pallets 1000 × 1200 crossways

|

Ast (mm)

|

1600

|

|

4.35

|

Turning radius

|

Wa (mm)

|

1880

|

|

4.38

|

Distance to swivelling-fork pivot

|

l8 (mm)

|

671

|

|

5.1

|

Travel speed, laden/unladen

|

km/h

|

8/8.5

|

|

5.2

|

Lift speed, laden/unladen

|

m/s

|

205/293

|

|

5.3

|

Lowering speed, laden/unladen

|

m/s

|

339/337

|

|

5.4

|

Reaching speed, laden/unladen

|

m/s

|

150/150

|

|

5.1

|

Service brake

|

|

Electromagnetic

|

|

6.1

|

Drive motor rating S2 60 min

|

kW

|

6.5

|

|

6.2

|

Lift motor rating at S3 15%

|

kW

|

8.2

|

|

6.4

|

Battery voltage/nominal capacity K5

|

(V)/(Ah) or kWh

|

48/450

|

|

6.5

|

Battery weight

|

kg

|

710

|

|

10.7

|

Sound pressure level at the driver’s seat

|

dB (A)

|

70

|

|

6.2

|

Lift motor rating at S3 15%

|

kw

|

12.0(AC)

|

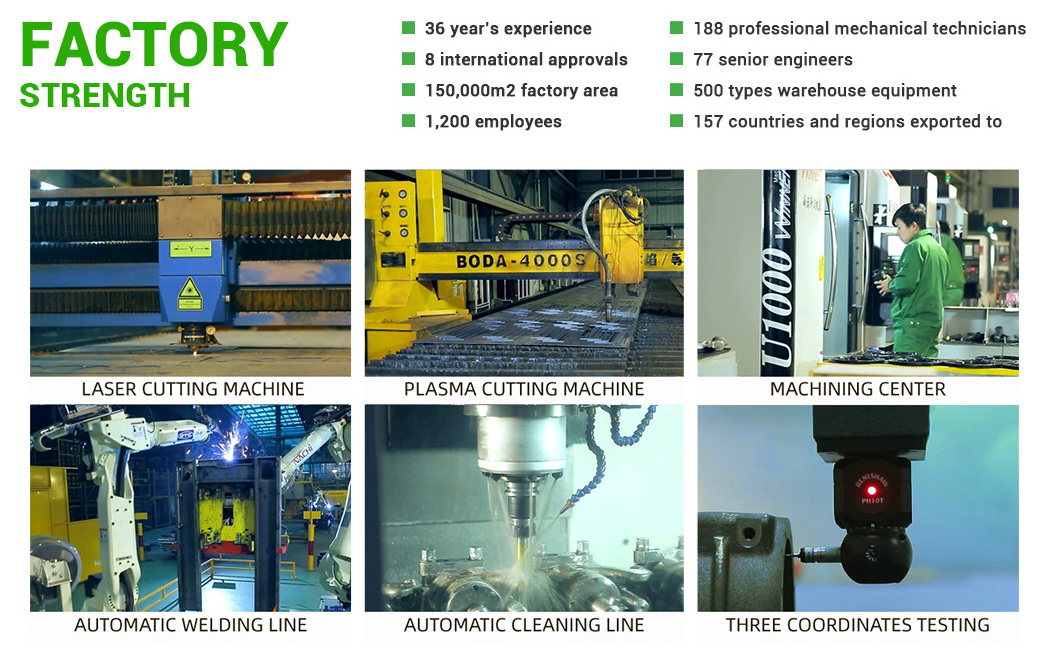

Advantages

* With full AC system and large-capacity battery, which can be used by two shifts in one charge.

* CAN BUScommunication technology is adopted.

* Equipped with electric power steering (EPS) with the function of driving wheel automatic return.

* The Lateral forkcan rotate left and right in 180 degrees .

* With central control instrument, which integrates operator's permission setting, running status display, operation control,

fault display, multilingual interface, etc.

* AC motor regenerative braking, reverse braking, ramp anti-sliding, etc.

* Electromagnetic brakewith short braking distance and no inertia impact, it is safe and reliable.

STRUCTURAL

* Integrated layout designof console, all operations can be completed by one hand.

* Seat with adjustable backrest angle, front and rear position and shock absorption function.

* The whole steering wheelcan be telescopically adjusted.

* Handrailsare designed on the left and right sides of the frame, convenient for operators to get on and off.

* The mast adopts the guiding structure design and the roof guard frame adopts a brand-new structure.

EASY MAINTENANCE

* One-piece upper coverwith fully open housing, it is convenient to maintain.

* Sideway moving batteryis easy for maintenance and replacement.

STANDARD

* Multi-way valve operating system

* EPS system

* Germany imports special mast

* Self-made reduction gearbox

* Finger-toggling operating switch

* Side-way battery

* Warning lights and headlights

OPTION

* Height positioning system

* Camera and display system

Pictures shows

Customer Evaluation

Packaging & Loading

Certifications

ISO9002:1995

ISO9001:2008(Quality management system)

ISO14001:2004(Environmental management system)

OHSAS18001:2007(Occupational Health and Safety management system)

We got TUV/GS/CE certificate for hand pallet truck early in 1991,who was the first manufacture in China.For material handling

equipment of Manual Lift Trucks and Electric Lifting Trucks,up to 90% products have approved CE certificate from TUV,our products

have approved CE standards of EN3691-5:2014 and EN3691-1:2012

ISO9001:2008(Quality management system)

ISO14001:2004(Environmental management system)

OHSAS18001:2007(Occupational Health and Safety management system)

We got TUV/GS/CE certificate for hand pallet truck early in 1991,who was the first manufacture in China.For material handling

equipment of Manual Lift Trucks and Electric Lifting Trucks,up to 90% products have approved CE certificate from TUV,our products

have approved CE standards of EN3691-5:2014 and EN3691-1:2012

Hot Searches