- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2500*1060*2800mm

-

Weight (KG):

-

2500 KG

-

Marketing Type:

-

Hot Product

-

Product name:

-

Radial Drilling Machine

-

Application:

-

Metal Processing

-

Machine type:

-

Mechanical or Hydraulic

-

Function:

-

Deep Hole Processing

-

Max. drilling diameter:

-

60-350 Mm

-

Spindle travel:

-

580-1200mm

-

Precision:

-

Accuracy

-

Spindle taper:

-

MT6

-

Driving mode:

-

Servo Motor Drive

-

Table drill:

-

Drill Press Auto-feed Drilling Machine

Quick Details

-

type:

-

Radial Drilling Machine

-

Max. Drilling Dia. (mm):

-

100

-

Range of Spindle Speed(r.p.m):

-

15 - 1440 r.p.m

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2500*1060*2800mm

-

Weight (KG):

-

2500 KG

-

Marketing Type:

-

Hot Product

-

Product name:

-

Radial Drilling Machine

-

Application:

-

Metal Processing

-

Machine type:

-

Mechanical or Hydraulic

-

Function:

-

Deep Hole Processing

-

Max. drilling diameter:

-

60-350 Mm

-

Spindle travel:

-

580-1200mm

-

Precision:

-

Accuracy

-

Spindle taper:

-

MT6

-

Driving mode:

-

Servo Motor Drive

-

Table drill:

-

Drill Press Auto-feed Drilling Machine

Product Description

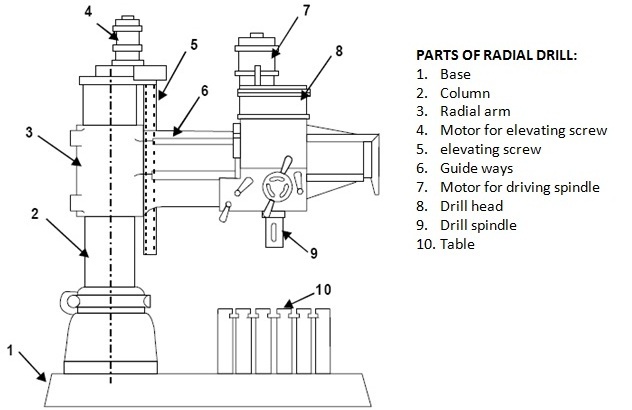

Radial Drilling Machine

Radial drilling machine is a kind of hole processing equipment, which can be used for drilling, reaming, reaming, tapping, end face repair and other forms of processing. According to the clamping structure of machine tools, radial drills can be divided into hydraulic radial drilling machines and mechanical radial drilling machines. Among all kinds of drilling machines, radial drilling machines are easy to operate, flexible, widely applicable and typical, especially suitable for single piece or batch production of holes with large porous parts. They are common machine tools in general machining workshops.

Main structure

The rocker drilling machine mainly consists of a base, inner column, outer column, rocker arm, spindle box, and workbench.

The inner column is fixed at one end of the base, and an outer column is sheathed outside it. The outer column can rotate 360 degrees around the inner column. One end of the rocker arm is a sleeve, which moves up and down on the outer column. Due to the integration of the screw rod and the outer column, while the lifting nut is fixed on the rocker arm, the rocker arm cannot rotate around the outer column and can only rotate around the inner column together with the outer column.

The spindle box is a composite component composed of the main transmission motor, spindle and spindle transmission mechanism, feed and speed change mechanism, and the operating mechanism of the machine tool. The spindle box is installed on the horizontal guide rail of the rocker arm and can be operated by a handwheel to move along the rocker arm on the horizontal guide rail.

Specification

|

Specification

|

Z3032X10

|

Z3040X14

|

Z3050X16

|

Z3063X18

|

Z3080X20

|

|

Max drilling diameter (mm)

|

32

|

40

|

50

|

63

|

80

|

|

Distance between spindle axis and coulumn(mm)

|

170-1100

|

260-1210

|

350-1500

|

400-1600

|

550-1600

|

|

Spindle travel(mm)

|

120

|

260

|

350

|

400

|

450

|

|

Spindle taper(morse)

|

MT4

|

MT4

|

MT5

|

MT6

|

MT6

|

|

Number of spindle speeds

|

6

|

12

|

12

|

16

|

16

|

|

Steps of spindle feeds

|

3

|

3

|

4

|

16

|

16

|

|

Radial ratation angle

|

360

|

360

|

360

|

180

|

180

|

|

Main motor (kw)

|

1.5

|

2.2

|

4

|

5.5

|

7.5

|

Details Images

Spindle box

The headstock is a composite component, which is composed of the main drive motor, the main shaft and the spindle transmission mechanism, the feed and speed change mechanism, the operating mechanism of the machine tool and other parts. The headstock is mounted on the horizontal rail of the rocker arm and can be operated by a handwheel so that it moves along the rocker arm on the horizontal rail.

Worktable

Generally, when drilling workpieces, the workpieces are often clamped on the table. When machining large workpieces, the workpiece can be clamped on the base of the drilling machine. According to the height of the workpiece, after releasing the locking device, the rocker arm can be moved up and down along the column, so that the headstock and drill bit are in the appropriate height position.

Double column

The inner column is fixed at one end of the base, and on the outside of it is set an outer column, which can rotate 360 degrees around the inner column. One end of the rocker arm is a sleeve, which moves up and down on the outer column. Since the screw is integrated with the outer column, and the lifting nut is fixed on the rocker arm, the rocker arm cannot rotate around the outer column, but can only rotate around the inner column together with the outer column.

Hot Searches