- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

jiesheng

-

Liquid Flow Rate:

-

customized

-

Maximum Working Pressure:

-

3.0MPa

-

Weight:

-

300 KG, DESIGNED

-

Dimension(L*W*H):

-

customized

-

Warranty:

-

1 Year

-

Product Type:

-

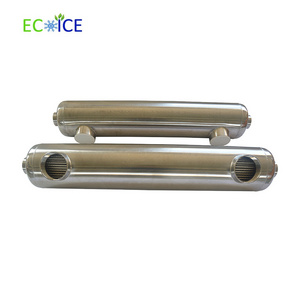

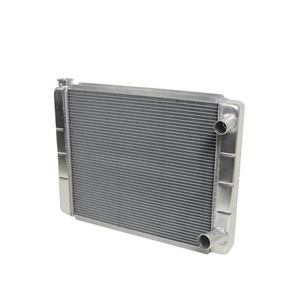

Excellent aluminum ceramic 316l shell and tube heat exchanger

-

Capacity Type:

-

Heavy Duty

-

Application:

-

Heating or Cooling

-

Shell side:

-

Water/salt water

-

Is-customized:

-

Yes

-

Material:

-

SS304/SS316

-

Model Number:

-

Immersion Heater

Quick Details

-

Structure:

-

Tube Heat Exchanger

-

Voltage:

-

220V/380V, 220V/380V

-

Applicable Industries:

-

Chmeical Environment

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

jiesheng

-

Liquid Flow Rate:

-

customized

-

Maximum Working Pressure:

-

3.0MPa

-

Weight:

-

300 KG, DESIGNED

-

Dimension(L*W*H):

-

customized

-

Warranty:

-

1 Year

-

Product Type:

-

Excellent aluminum ceramic 316l shell and tube heat exchanger

-

Capacity Type:

-

Heavy Duty

-

Application:

-

Heating or Cooling

-

Shell side:

-

Water/salt water

-

Is-customized:

-

Yes

-

Material:

-

SS304/SS316

-

Model Number:

-

Immersion Heater

Product Details

|

Shell and Tube Heat Exchanger

design is one of the most common types of exchangers used in heat transfer.

Typically used in applications when a process requires large amounts of fluid to be heated or cooled.

As a result of their design,shell and tube heat exchanger offer a large surface area and thus high heat transfer efficiency.

There are many different types or designs of shell and tube heat exchanger to meet various process requirements in almost every industry.

Shell and Tube heat exchanger can provide reliable heat transfer by utilizing multiple passes of one or both fluids. One

(1), two (2) and four (4) pass models are usually the standard, however multi-pass custom models are available. Shell and Tube heat exchanger use baffles on the shell-side fluid to accomplish mixing or turbulence. Without the use of baffles, the fluid can become stagnant in certain parts of the shell. |

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

Work Flow

Recommend Products

Hot Searches