- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

200 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

can be customed

-

Application:

-

Vegetable and fruit

-

Function:

-

Tomato sauce production line

-

Material:

-

304 Stainless Steel

-

Capacity:

-

500kg/h

-

Final product:

-

Tomato sauce machine

-

Key words:

-

Tomato sauce

-

MOQ:

-

1 Set

-

Application scope:

-

Fruit Processing Industries

-

Advantage:

-

Water Recycle

-

Applicable Industries:

-

Restaurant

Quick Details

-

Machinery Capacity:

-

2000

-

Year:

-

2019

-

Dimension(L*W*H):

-

1.55*0.8*2.2

-

Weight:

-

200 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

can be customed

-

Application:

-

Vegetable and fruit

-

Function:

-

Tomato sauce production line

-

Material:

-

304 Stainless Steel

-

Capacity:

-

500kg/h

-

Final product:

-

Tomato sauce machine

-

Key words:

-

Tomato sauce

-

MOQ:

-

1 Set

-

Application scope:

-

Fruit Processing Industries

-

Advantage:

-

Water Recycle

-

Applicable Industries:

-

Restaurant

Product Description

This production line is used to produce tomato paste, high automation, easy operation, flow operation. When production tomato sauce, note that in the process of pretreatment of fruits and vegetables, which has much pesticide residue, when cleaning add dilute hydrochloric acid or fatty acids for processing; For microbial contamination, available a certain concentration of bleaching

powder or potassium permanganate solution soaked, and then rinse. In most fruit broken, must be preheated before juice treatment,

powder or potassium permanganate solution soaked, and then rinse. In most fruit broken, must be preheated before juice treatment,

Specification

|

Product Name

|

|

Tomato Paste Production Line

|

|

||

|

No

|

Machine Name

|

Specification

|

9kw

|

||

|

1

|

Tomato Washing Machine

|

100kg/h

|

12kw

|

||

|

2

|

Tomato Crushing Machine

|

100kg/h

|

18kw

|

||

|

3

|

Feeding Pump

|

100kg/h

|

22kw

|

||

|

4

|

Tomato Preheating Machine

|

100kg/h

|

30kw

|

||

|

5

|

Tomato Pulping Machine

|

120kg/h

|

|

||

|

6

|

Storage Tank

|

300L

|

|

||

|

7

|

Vacuum Concentrating Machine

|

300L

|

|

||

|

8

|

Screw Pump

|

0.1T/H

|

|

||

|

9

|

Finished Product Tank

|

1T

|

|

||

|

10

|

Screw Pump

|

0.1T/H

|

|

||

|

11

|

Tomato Paste Packing Machine

|

Customized

|

|

||

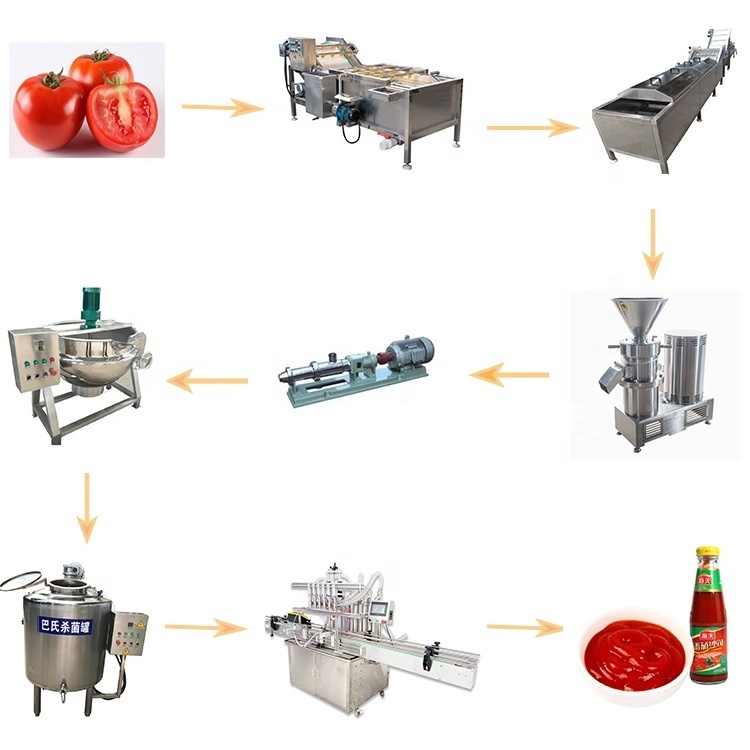

Working principles

Raw materials → hoist machine → surf-washing machine →Roller Fruit Spray Machine-→

Waste Fruit Conveyor→Lifting machine-→ Hammer Crusher-→ low tank-→ belt propeller single screw pump-→ preheater-→ pulping Refining Machine (can also be used cold pulping machine)-→ buffer tank-→ Fruit slag Conveyor.

Tubular outer circulation evaporator-→ single screw pump-→ thick slurry tank-→ thick slurry pump-→ casing sterilizer-→ filling Machine-→ sterilization pot two times sterilization-→ conveyor-→ labeling Machine-→ calibration Machine-→ Inkjet machine-→finished packing.

Waste Fruit Conveyor→Lifting machine-→ Hammer Crusher-→ low tank-→ belt propeller single screw pump-→ preheater-→ pulping Refining Machine (can also be used cold pulping machine)-→ buffer tank-→ Fruit slag Conveyor.

Tubular outer circulation evaporator-→ single screw pump-→ thick slurry tank-→ thick slurry pump-→ casing sterilizer-→ filling Machine-→ sterilization pot two times sterilization-→ conveyor-→ labeling Machine-→ calibration Machine-→ Inkjet machine-→finished packing.

Our Advantages

1) All the machines are made of SUS 304, 316L optional.

2) Finally Packaging: usually, filled with aseptic bag in drum or aseptic bag in box. and then packed with small packaging. such

as: plastic bottle, glass bottle, can, jar, tetra pack etc.

3) The line is also suitable for processing the fruits that share the similar characteristics.

4)Adopt 'hot-break' or 'cold-break' techniques to produce fruit paste which is different viscosity.

5) The production process fully automatic PLC control to save labor and faciliate production management.

6) Low-temperature vacuum evaporation, maximize reserve the flavor substances and nutrients, also save energy.

7) Tubular UHT Sterilizer and aseptic filling machine, produce high-quality fruit paste products.

8) Automatic CIP cleaning to ensure food hygiene and safety requirements of the whole line.

9) Our machine parts adopt the world famous brand: PLC,touch screen generally use the brand: SIEMENS,Germany. Switch usually use SCHNEIDER, France and OMRON, Japan. Steam valves commonly use SpiraxSarco, UK.

2) Finally Packaging: usually, filled with aseptic bag in drum or aseptic bag in box. and then packed with small packaging. such

as: plastic bottle, glass bottle, can, jar, tetra pack etc.

3) The line is also suitable for processing the fruits that share the similar characteristics.

4)Adopt 'hot-break' or 'cold-break' techniques to produce fruit paste which is different viscosity.

5) The production process fully automatic PLC control to save labor and faciliate production management.

6) Low-temperature vacuum evaporation, maximize reserve the flavor substances and nutrients, also save energy.

7) Tubular UHT Sterilizer and aseptic filling machine, produce high-quality fruit paste products.

8) Automatic CIP cleaning to ensure food hygiene and safety requirements of the whole line.

9) Our machine parts adopt the world famous brand: PLC,touch screen generally use the brand: SIEMENS,Germany. Switch usually use SCHNEIDER, France and OMRON, Japan. Steam valves commonly use SpiraxSarco, UK.

Product feature

Nowadays ketchup is more and more widely used in food.Became a new food field.This makes more people want to develop in this

field.The ketchup production line includes cleaning,screening and dressing, hot stamping, beating ,heating and concentration,

ingredients, filling,sterilization, cooling,finished products

field.The ketchup production line includes cleaning,screening and dressing, hot stamping, beating ,heating and concentration,

ingredients, filling,sterilization, cooling,finished products

Packing & Delivery

Hot Searches