- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V,380V,415V, 480V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DALSON

-

Dimension(L*W*H):

-

1750*850*1300mm (As Fact)

-

Weight:

-

200 KG

-

Machinery Capacity:

-

150bottles/min

-

Product name:

-

Automatic Round Bottle Jars Sticker Adhesive label applicator Machine

-

Model:

-

DSL Series

-

Capacity/Speed:

-

150~200Bottles/Min

-

Applicable Product:

-

Plastic Bottle, Glass Bottle, Jars, CupsCarton Box,etc

-

Hot Shrink Mode:

-

Hot Steam Shrink, Electrical Hot Air Shrink

-

Accept Sleeve Labeling Position:

-

Bottle Body, Bottle Cap, Bag Top, Carton Sides, etc

-

PLC:

-

SIEMENS, Mitsubishi,Schneider

-

Touch Screen:

-

SIEMENS, Schneider

-

Power Supply:

-

1.5KW, 220V/380V,3Phase, 50Hz/60Hz

-

Operational mode:

-

Intelligent Touch Screen

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Saudi Arabia, Indonesia, Thailand, UAE, Colombia, Bangladesh

-

After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Marketing Type:

-

Hot Product 2019

-

Certification:

-

ISO, CE

Quick Details

-

Application:

-

Food, Beverage, Medical, Chemical, Daily Chemical Products

-

Packaging Type:

-

Bottles

-

Packaging Material:

-

Plastic, Paper, Metal, Glass, Wood

-

Voltage:

-

220V,380V,415V, 480V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DALSON

-

Dimension(L*W*H):

-

1750*850*1300mm (As Fact)

-

Weight:

-

200 KG

-

Machinery Capacity:

-

150bottles/min

-

Product name:

-

Automatic Round Bottle Jars Sticker Adhesive label applicator Machine

-

Model:

-

DSL Series

-

Capacity/Speed:

-

150~200Bottles/Min

-

Applicable Product:

-

Plastic Bottle, Glass Bottle, Jars, CupsCarton Box,etc

-

Hot Shrink Mode:

-

Hot Steam Shrink, Electrical Hot Air Shrink

-

Accept Sleeve Labeling Position:

-

Bottle Body, Bottle Cap, Bag Top, Carton Sides, etc

-

PLC:

-

SIEMENS, Mitsubishi,Schneider

-

Touch Screen:

-

SIEMENS, Schneider

-

Power Supply:

-

1.5KW, 220V/380V,3Phase, 50Hz/60Hz

-

Operational mode:

-

Intelligent Touch Screen

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Saudi Arabia, Indonesia, Thailand, UAE, Colombia, Bangladesh

-

After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Marketing Type:

-

Hot Product 2019

-

Certification:

-

ISO, CE

Shanghai Dalson Packing Machinery Co.,Ltd.

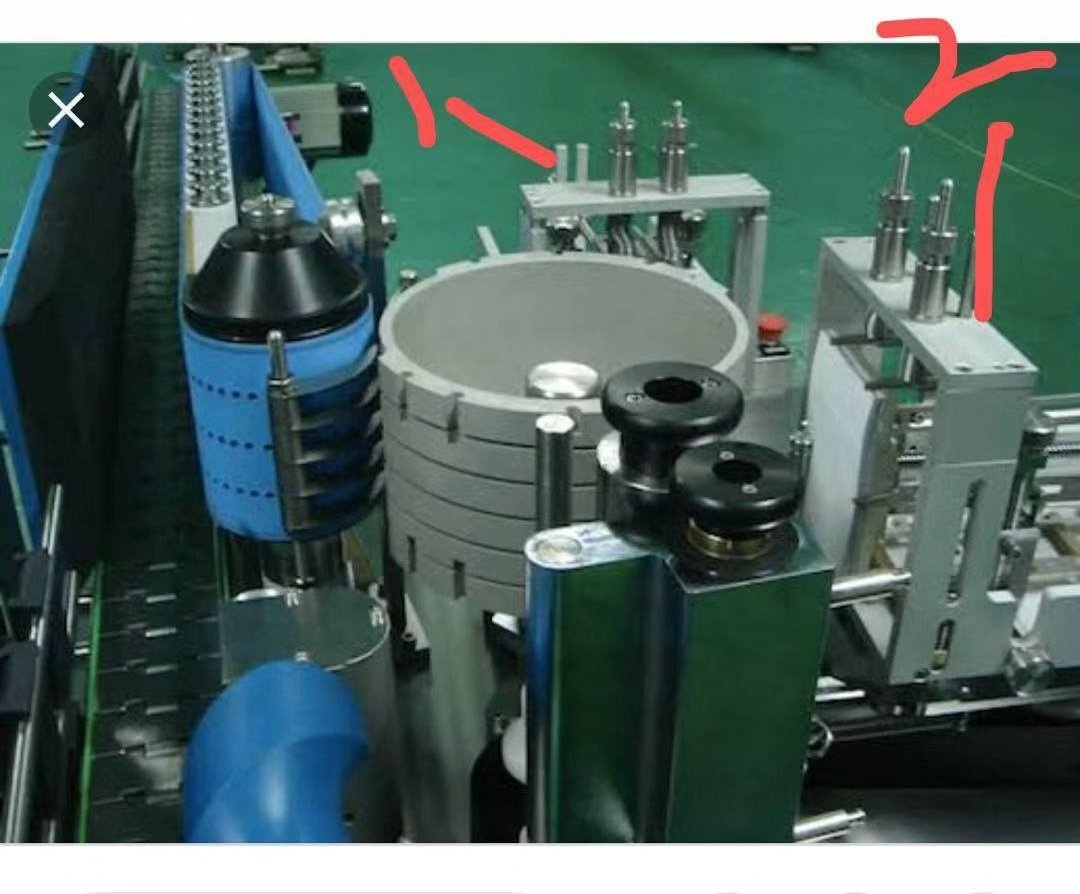

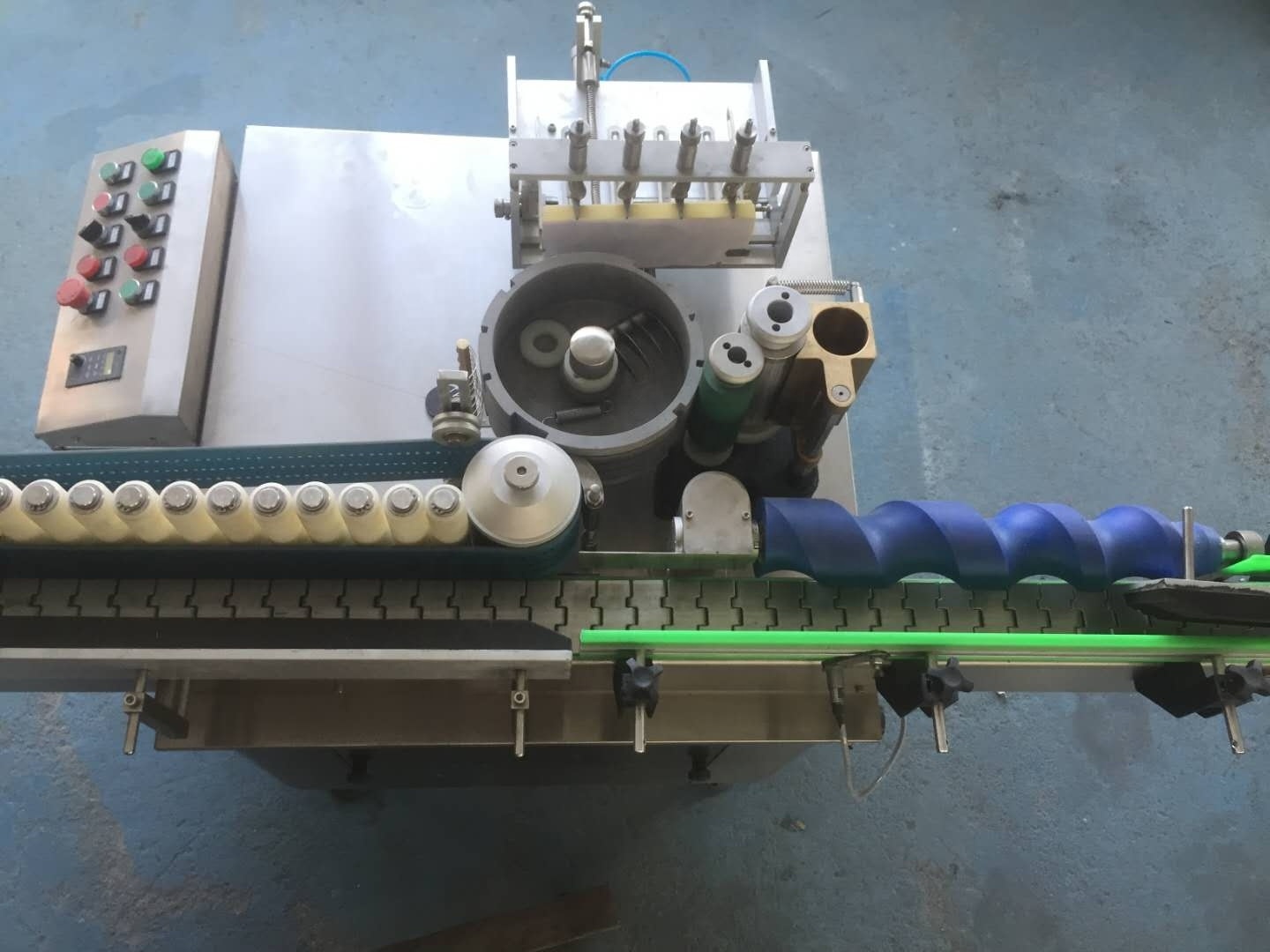

Series Full Automatic Cold Wet Glue Sticker/Adhesive Labeling Machine

1. Whole machine use 304 stainless steel and advanced aluminum alloy, meet the GMP requirement.

2. Automatic label sending, automatic pasting, automatic labeling which highly improve labeling efficiency.

3. Advanced compatible human-machine interface system, simple and intuitive, full of functions, with rich online help functions.

4. Using rotary-screw guide the bottles on conveyor, the bottle runs smoothly and the positioning is reliable. Using the rolling mechanism, the label pasting is good, the reliability of the labeling is enhanced, the protection device is equipped with no bottle sent, no label out, no paste, no labeling and so on.

5. The high purity copper glue box is matched with the stainless steel roller to make the process precise. The glue thickness can be adjusted according to the need, and the glue is equal, so as to eliminate the waste of glue and the phenomenon of glue leakage.

6. The special rubber roller is treated by several processes without deformation and wear resistance. The glue is uniform and light, and the amount of glue is saved.

7. Intelligent control, automatic photoelectric tracking, when no object and no labeling, no label automatic correction and automatic label detection function, to prevent glue leakage and label waste.

8. With the vacuum suction system and the belt cooperation, the label can paste on bottle smoothly .

9. Using the frequency converter, the speed of the motor can be adjusted freely and the labeling capacity is controlled freely.

10. The separation design of glue box, coated rubber wheel and rotating tower, make simple and quick cleaning.

11. The whole machine is selected by the world famous electric configuration to ensure the quality, make it more stable, longer use and less maintenance.

12. The speed of labeling, transport and bottle separating can realize stepless speed regulation, and adjust according to the need.

13. The adjustment is simple, the replacement of a small number of parts such as the turret, the vacuum belt and so on, can be quickly adjusted and satisfied with various specifications of the bottle. And the adjustment factors can be excluded to the maximum.

14.It can work alone, and also can connect the production line.

Machine Characteristics:

1. Adopt intelligent HMI to control and display the machine running action status and with alarm function in real time.

2. Through multiple buffer design to realize gently and smoothly labeling on bottle, and maximum ensure labeling accuracy.

3. Packing speed is adjustable (controlled by frequency converter).

4. Automatic alarm for lack of bottles or labels etc, effectively reducing the probability of labeling error.

5. Equipped with the safety protection function of accidental or fault gives alarm warning and the indicator light flashes .

DALSON Main Products Orientation:

1. Various Carton Erector, Carton Packer, Carton Sealer Machines;

2. Various Labeling Machines ;

3. Various Conveyors ;

4. Various PE Film Shrink Wrapper Case Packing Machines ;

5. Various Palletizer and Depalletizer Machines ;

6. Pallet Shape Products PP/PET/SteeL Belt Strapping Machine ;

7. M & A and expansion of filling machine business ;

8. Special Machines Design ;

9. Whole Line Support,Manufacturer and Professional After-sale Service.