- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Taiwan quality

-

Brand Name:

-

Huarui

-

Voltage:

-

380v or customize

-

Power:

-

0.75-15kw

-

Dimension(L*W*H):

-

1.3*0.75*0.9

-

Weight:

-

1500

-

Product name:

-

Top 1 Self Drilling Screw Machine for Sale

-

Raw material:

-

steel , stainless steel

-

Machine Type:

-

self drilling screw manufacturing machine

-

Keyword:

-

self drilling screw

-

Related machine:

-

Cold heading machine

-

Assembly machine:

-

Washer and screw assembly machine

-

Usage:

-

Point Tail End Drilling Forging Machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Application:

-

machines for making nails and screws

-

Production Capacity:

-

300pcs/month

-

Marketing Type:

-

Taiwan quality

-

Brand Name:

-

Huarui

-

Voltage:

-

380v or customize

-

Power:

-

0.75-15kw

-

Dimension(L*W*H):

-

1.3*0.75*0.9

-

Weight:

-

1500

-

Product name:

-

Top 1 Self Drilling Screw Machine for Sale

-

Raw material:

-

steel , stainless steel

-

Machine Type:

-

self drilling screw manufacturing machine

-

Keyword:

-

self drilling screw

-

Related machine:

-

Cold heading machine

-

Assembly machine:

-

Washer and screw assembly machine

-

Usage:

-

Point Tail End Drilling Forging Machine

High speed drilling tail forming machine /Automatic self drilling screw forming machine

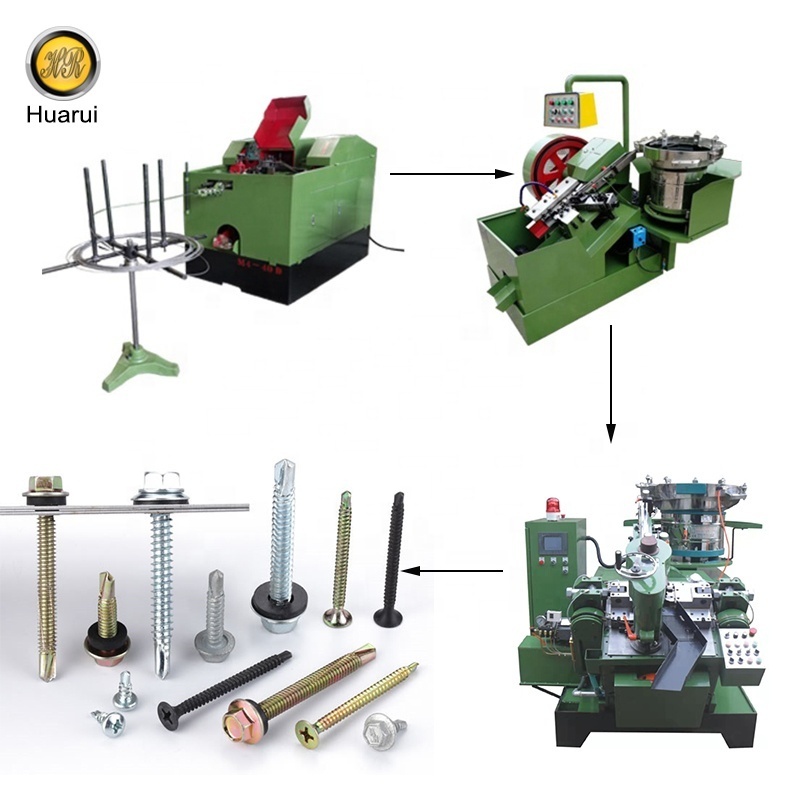

Process Flow

Step 1: Screw heading machine

Step 2:Thread rolling machine

Step 3: Self drilling screw forming machine

This equipment adopts cam surface design, does not affect the processing of forming the molding cycle time, can extend the time of stamping, and reduce the air travel time, to achieve good characteristics of the movement to ensure that mold life.

HRC60 ° grinding precision, rolling friction wear less, perfect zero backlash curve.

High-speed no noise, no energy waste.

High precision, OPR, absolute synchronization.

Simple structure Screw drive, very few failures.

|

Model

|

HR14-130L

|

|

Speed

|

120-520PCS/Minute

|

|

Main Motor

|

7.5KW(10HP)

|

|

Oil pump motor

|

0.75KW(1HP)

|

|

elevator motor

|

0.2KW(1/4HP)

|

|

Inverter

|

7.5KW

|

|

Brake System

|

Air-Pressure Clutch

|

|

Auto-action controller

|

PLC Controller

|

|

Abnormal auto-action

|

Automatically detect abnormal man-machine interface display

|

|

Vibrator Feeder

|

620mm,Plus Silent PU Gelatin Spraying

|

|

Wire Diameter

|

#6(2.8)~#14(5.45)NO.1-NO.6

|

|

Screw Length

|

9.5mm~130mm

|

|

Machine Size(L*W*H)

|

1950mm* 1650mm*1650mm

|

|

Machine weight

|

(approx)2180KG

|

End products

Contact us

If you are interested in our machine, please contact us :

Mob/Whatsapp/Wechat/Viber:

+86 13937476212

Skype:

bella.huarui

Hot Searches