- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Waterproof Projects

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LX GCL

-

Model Number:

-

GCL NP

-

Specification:

-

3000g-6000g/m2

-

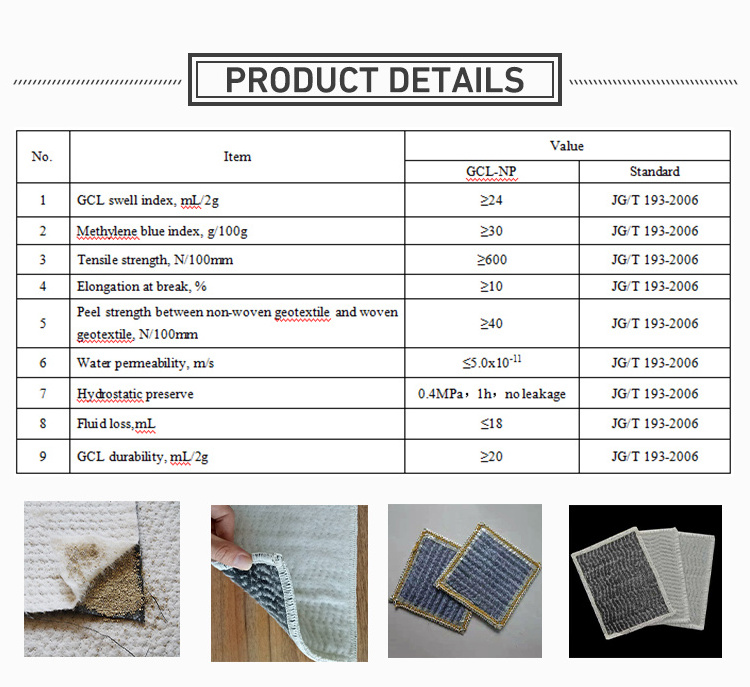

GCL swell index:

-

≥24mL/2g

-

Methylene blue index:

-

≥30g/100g

-

Tensile strength:

-

≥600N/100mm

-

Elongation at break:

-

≥10%

-

Peel strength between the geotextiles:

-

≥40N/100mm

-

Water permeability:

-

≤5.0x10-11m/s

-

Hydrostatic preserve:

-

0.4MPa,1h,no leakage

-

Fluid loss:

-

≤18ml

-

GCL durability:

-

≥20mL/2g

-

COLOR:

-

Black White Green Blue

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Free spare parts

-

Project Solution Capability:

-

graphic design, 3D model design, Cross Categories Consolidation

-

Application:

-

Waterproof Projects

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LX GCL

-

Model Number:

-

GCL NP

-

Specification:

-

3000g-6000g/m2

-

GCL swell index:

-

≥24mL/2g

-

Methylene blue index:

-

≥30g/100g

-

Tensile strength:

-

≥600N/100mm

-

Elongation at break:

-

≥10%

-

Peel strength between the geotextiles:

-

≥40N/100mm

-

Water permeability:

-

≤5.0x10-11m/s

-

Hydrostatic preserve:

-

0.4MPa,1h,no leakage

-

Fluid loss:

-

≤18ml

-

GCL durability:

-

≥20mL/2g

-

COLOR:

-

Black White Green Blue

Geosynthetic Clay Liner

GCL

Product Description

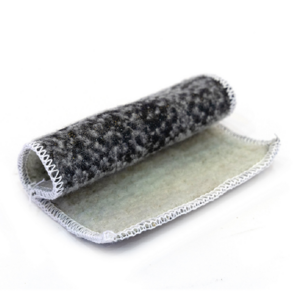

The GCL is punched together with non-woven geotextile, woven geotextile and bentonite. Width of the geosynthetic clay liners can be up to 6m and length of 60m. The middle level is bentonite grains, which are carefully selected crude and filled in between the two levels after special processing. The bentonite grain in GCL made by this method does not flow in a fixed direction. It distributes evenly and forms waterproof layer, owning excellent waterproof effect. This GCL is a kind of new green waterproof materials, which are widely applied in many waterproof construction projects. GCL can be applied separately, or combined with high density polyethylene (HDPE).

GCL sodium bentonite geosynthetic clay liner is a new type of geosynthetic material, and it can be divided into needle-punctured GCL(GCL-NP) and needle-punctured coated GCL(GCL-OF). GCL is a kind of bentonite seepage-proofing mat needle-punctured through filling sodium bentonite between woven geotextile and non-woven geotextile. Among which tiny fiber spaces can be formed to prevent bentonite particles to move to a direction. It can form glue-type water-proofing layer to prevent water leakage. Woven geotextile of 120g/㎡ and non-woven geotextile of 220g/㎡ are applied in this kind of GCL.

GCL sodium bentonite geosynthetic clay liner is a new type of geosynthetic material, and it can be divided into needle-punctured GCL(GCL-NP) and needle-punctured coated GCL(GCL-OF). GCL is a kind of bentonite seepage-proofing mat needle-punctured through filling sodium bentonite between woven geotextile and non-woven geotextile. Among which tiny fiber spaces can be formed to prevent bentonite particles to move to a direction. It can form glue-type water-proofing layer to prevent water leakage. Woven geotextile of 120g/㎡ and non-woven geotextile of 220g/㎡ are applied in this kind of GCL.

Mass per unit of GCL sodium bentonite clay liner can be divided into: 4000g/㎡, 4500g/㎡, 5000g/㎡, 5500g/㎡, etc. The length of the product is 30m, and the width is 6m.

Specification

Application

GCL sodium bentonite clay liner is applied specially in seepage-proofing in constructions such as artificial lake, landfill,

underground garage, roof garden, pool, oil depot, storage yard for chemical s, etc. The cost performance is good, and applications are wide.

underground garage, roof garden, pool, oil depot, storage yard for chemical s, etc. The cost performance is good, and applications are wide.

Backfill:

1.GCLs(bentonite clay liner )paved must be backfilled on the day.

2.The sand or the sifted soil is the best choice, and the soil should not have impurity with more than10mm.

3.The soil must be tamped every backfilling 50cm, and the degree of density should be more than 85%.

4.Pay attention to the GCLs when tamping, it can not be damaged.

5.When backfilling in the planar surface, the thickness should be 30cm at least.

1.GCLs(bentonite clay liner )paved must be backfilled on the day.

2.The sand or the sifted soil is the best choice, and the soil should not have impurity with more than10mm.

3.The soil must be tamped every backfilling 50cm, and the degree of density should be more than 85%.

4.Pay attention to the GCLs when tamping, it can not be damaged.

5.When backfilling in the planar surface, the thickness should be 30cm at least.

Performance:

1. Environment friendly

It is raw and natural materials,;aging and corrosion seldom happen. It can keep its quality and then it does not cause any

injuries and pollution for human and the environment. It is not only waterproof, but also has good ventilation performance. It can stick up for the exchange of the ecological environment. It is a pure natural, new, green waterproof material.

2. Permanent waterproof, excellent performance

Its waterproof properties are much more durable than that of the buildings. Sodium bentonite would transform to high density septum under hydro pressure. When The thickness is 3mm, the permeability is below a*10-11/sec(a=1~9), which equals to the density of 100 times of the clay with 30 mm thickness. Water retention performance is evident.

3. Easy to construct

Bentonite powder, nails and washers are enough for connection and fixation. Construction is not constrained by weather conditions and it could be taken under cold or wet conditions. Bentonite powder is spread on overlap point. When water comes, GCL would be overlapped automatically. It is so far the only material that starts the waterproof effect by water in the world. It is not necessary to take additional examination when the construction is completed. The repair works are easy in case of waterproof defects. Among the existing waterproof materials, GCLs construction period is the shortest and its operation is the easiest. It has an eminent effect on shortening the construction period as well as saving the cost.

4. Strong self-restore capacity

The integration between waterproof material and its target enables GCL a 20~28 times swelling volume. Even if concrete structure trembles or subsides, the bentonite in GCL would restore the crack of 2mm or below on the concrete structure immediately. Even if the diameter of perforation reaches 30 mm, the restoration will be finished within 15 days completely.

It is raw and natural materials,;aging and corrosion seldom happen. It can keep its quality and then it does not cause any

injuries and pollution for human and the environment. It is not only waterproof, but also has good ventilation performance. It can stick up for the exchange of the ecological environment. It is a pure natural, new, green waterproof material.

2. Permanent waterproof, excellent performance

Its waterproof properties are much more durable than that of the buildings. Sodium bentonite would transform to high density septum under hydro pressure. When The thickness is 3mm, the permeability is below a*10-11/sec(a=1~9), which equals to the density of 100 times of the clay with 30 mm thickness. Water retention performance is evident.

3. Easy to construct

Bentonite powder, nails and washers are enough for connection and fixation. Construction is not constrained by weather conditions and it could be taken under cold or wet conditions. Bentonite powder is spread on overlap point. When water comes, GCL would be overlapped automatically. It is so far the only material that starts the waterproof effect by water in the world. It is not necessary to take additional examination when the construction is completed. The repair works are easy in case of waterproof defects. Among the existing waterproof materials, GCLs construction period is the shortest and its operation is the easiest. It has an eminent effect on shortening the construction period as well as saving the cost.

4. Strong self-restore capacity

The integration between waterproof material and its target enables GCL a 20~28 times swelling volume. Even if concrete structure trembles or subsides, the bentonite in GCL would restore the crack of 2mm or below on the concrete structure immediately. Even if the diameter of perforation reaches 30 mm, the restoration will be finished within 15 days completely.

Packing & Delivery

Certificate

FAQ

1. Are you a factory?

Yes

2. Is free sample available?

Yes

3. How long is the delivery time?

Within 15 days after receiving down payment.

4. What's the MOQ?

1*20GP, can be negotiated.

1*20GP, can be negotiated.

Hot Searches