- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

40

-

Place of Origin:

-

Jiangsu, China

-

Product name:

-

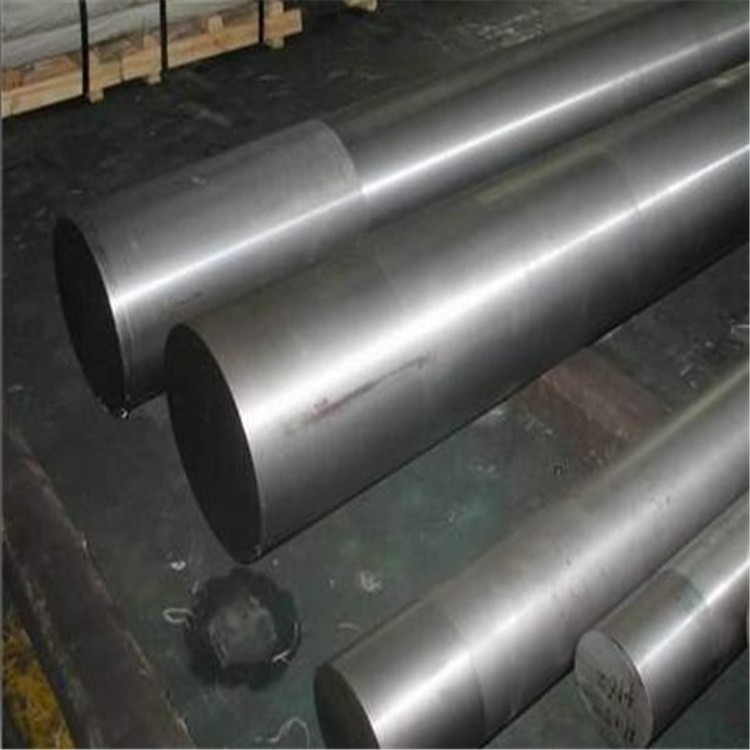

Monel 400/k-500 alloy steel round bar

-

Technique:

-

Cold Rolled Hot Rolled

-

Material:

-

Monel 400/k-500

-

Trading terms:

-

FOB CIF CFR CNF EXWORK

-

Materials Mill:

-

TISCO JISCO BAOSTEEL ZPSS LISCO

-

Certification:

-

SIO BV ISO

-

Audited:

-

SGS&BV&ISO&TUV

-

MOQ:

-

100 kgs

-

Shape:

-

round

Quick Details

-

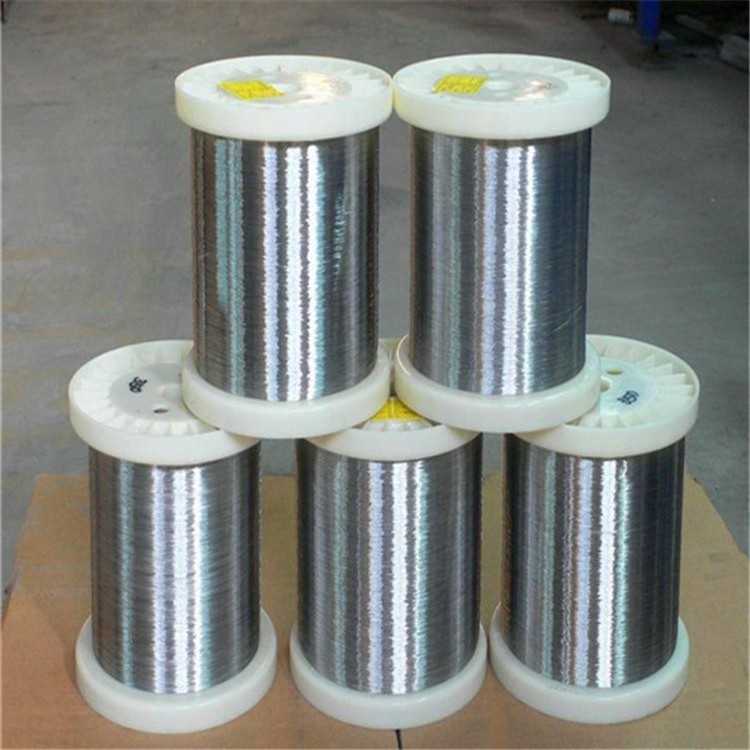

Resistance (μΩ.m):

-

25

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

600

-

Elongation (≥ %):

-

40

-

Place of Origin:

-

Jiangsu, China

-

Product name:

-

Monel 400/k-500 alloy steel round bar

-

Technique:

-

Cold Rolled Hot Rolled

-

Material:

-

Monel 400/k-500

-

Trading terms:

-

FOB CIF CFR CNF EXWORK

-

Materials Mill:

-

TISCO JISCO BAOSTEEL ZPSS LISCO

-

Certification:

-

SIO BV ISO

-

Audited:

-

SGS&BV&ISO&TUV

-

MOQ:

-

100 kgs

-

Shape:

-

round

Monel 400

Monel 400 material is a nickel-copper alloy (about 67% Ni – 23% Cu) that is resistant to sea water and steam at high temperatures as well as to salt and caustic solutions. Alloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloy exhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowing brackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to a variety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions. This nickel alloy is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated. As would be expected from its high copper content, alloy 400 is rapidly attacked by nitric acid and ammonia systems.

Chemical Composition %

Monel K-500

Monel K500 material is a nickel-copper alloy that combines the excellent corrosion resistance characteristic of Monel 400 with the added advantage of greater strength and hardness. These amplified properties, strength and hardness, are obtained by adding aluminum and titanium to the nickel-copper base and by a thermal processing used to effect precipitation, typically called age hardening or aging. When in the age-hardened condition, Monel K-500 has a greater tendency toward stress-corrosion cracking in some environments than Monel 400. Alloy K-500 has approximately three times the yield strength and double the tensile strength when compared with alloy 400. Plus, it can be further strengthened by cold working prior to precipitation hardening. The strength of this nickel steel alloy is maintained to 1200° F but stays ductile and tough down to temperatures of 400° F. Its melting range is 2400-2460° F.

Chemical Composition, %

With wide experience and expertise, Beall Industry Group is one of the leading monel400/k-500 manufacturers and suppliers. We have hundreds of high-qualified workers at your service. Please rest assured to get the competitive price for sale with us.

Beall promise best quality,competitive price and professional service.

1.Free sample is available.

2.Mill Test Certificate is supplied with shipment.

3.The third party inspection is accepted.

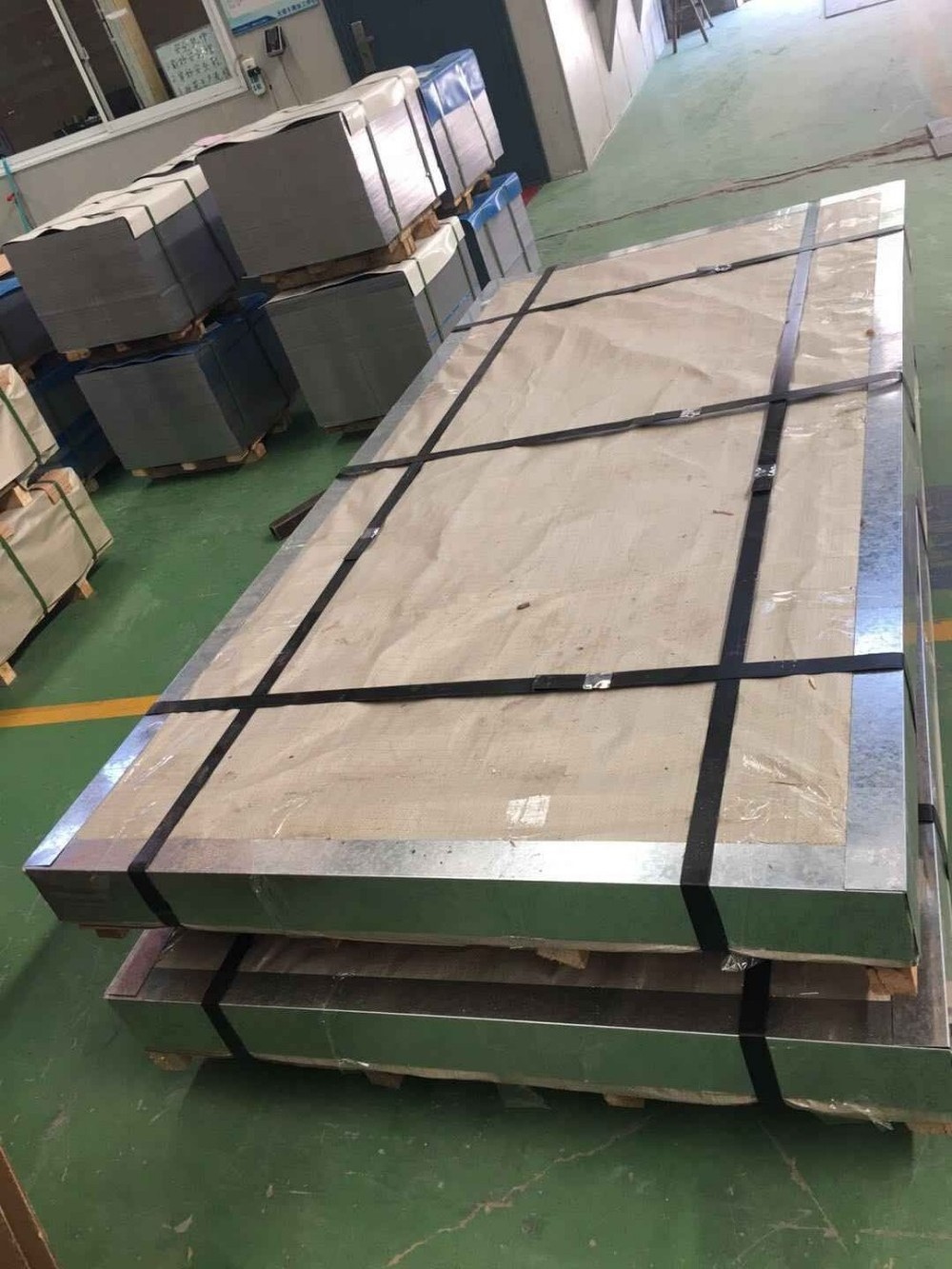

1:Package:

Plastic poly-bag, wooden case

All our products are packed, stored, transported according to the international regulation.

The tubes are wrapped with anti-rust paper and steel rings to prevent damage. Identification labels are tagged according to standard specification or customer's instructions.

Special packing is available as per customer's requirement.

Ply wooden box are available for special protection.

Other kinds of packing can be offered if request

2:Delivery : 15-30 days, according to the quantity

Beall Industry Group Co.,Limited is the leading manufacturer and supplier of stainless steel,duplex and super nickle alloy materials with 20 years experience of supplying to a great variety of end users from different fields.

Web: www.beallindustry.com

Tel No: 8621 60491702

Fax No: 8621 51385305

E-mail: sales025@ beallindustry.com

Phone/Wechat/Whatsapp:+86 135 8573 6602

Skype: beallindustry025

Att: Ada Xiang