- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2350*900*1900

-

Weight:

-

400 KG

-

Product name:

-

SS316L wiped film molecular distillation system

-

Model:

-

YMD-1S

-

Application:

-

FFood Beverage Chemical Haramceutical Industry

-

Function:

-

Extract Essential Oil

-

Evaporator film forming method:

-

Scraper

-

Evaporator material:

-

316L SS

-

Evaporator sealing form:

-

Magnetic force

-

Evaporation area:

-

0.1

-

Flow:

-

2L~5L/H

-

Feeding:

-

Gear pump

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

YHCHEM

-

Power:

-

370W

-

Dimension(L*W*H):

-

2350*900*1900

-

Weight:

-

400 KG

-

Product name:

-

SS316L wiped film molecular distillation system

-

Model:

-

YMD-1S

-

Application:

-

FFood Beverage Chemical Haramceutical Industry

-

Function:

-

Extract Essential Oil

-

Evaporator film forming method:

-

Scraper

-

Evaporator material:

-

316L SS

-

Evaporator sealing form:

-

Magnetic force

-

Evaporation area:

-

0.1

-

Flow:

-

2L~5L/H

-

Feeding:

-

Gear pump

Product Parameter

|

Model

|

YMD-06S

|

YMD-1S

|

YMD-2S

|

YMD-3S

|

YMD-5S

|

YMD-10S

|

YMD-20S

|

YMD-50S

|

|||||||

|

Feeding rate(L/h)

|

1~5

|

2~10

|

2~20

|

2~30

|

10~50

|

20~100

|

40~200

|

100~500

|

|||||||

|

Evaporation area(m²)

|

0.06

|

0.1

|

0.2

|

0.3

|

0.5

|

1

|

2

|

5

|

|||||||

|

Feeding tank

volume (L)

|

10

|

15

|

|

30

|

50

|

/

|

/

|

/

|

|||||||

|

Minimum operating pressure (mbar)

|

≤0.001

|

|

|

|

|

|

|

|

|||||||

|

Working temperature range (℃)

|

≤350

|

|

|

|

|

|

|

|

|||||||

|

Power supply

|

220V,50Hz,1p

|

|

|

|

|

|

|

|

|||||||

|

Profile Height (cm)

|

180

|

200

|

235

|

265

|

330

|

445

|

500

|

750

|

|||||||

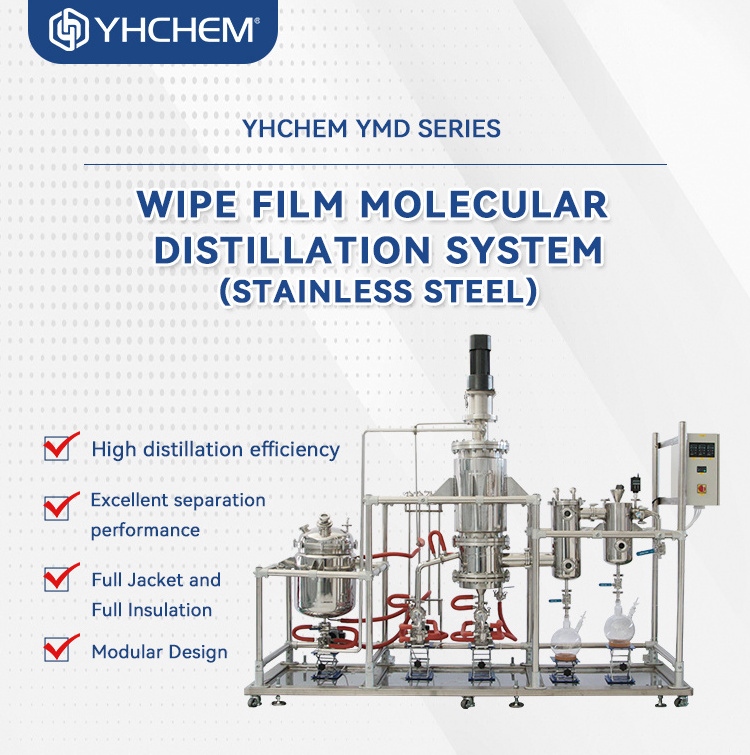

Product Description

YMD series Wipe Film Molecular Distillation System (Stainless Steel) is a type of molecular distillation equipment made of stainless steel, featuring high corrosion resistance and high temperature resistance.This system adopts the short path molecular distillation principle, heating the mixture to a high temperature to make each component evaporate separately and then recondense at a certain temperature, thus achieving the separation and purification of the mixture. The stainless steel short path molecular distillation system has high erintegration and better heat transfer efficiency, and can greatly increase productivity through the high-precision automatic feeding and discharge pump. lt is an idealchoice for pilot and industrial production equipment.

Rroduct Advantage

♣1.Stainless Steel 316L & PTFE

Good corrosion resistance, high temperature and pressure resistance, durability,high heat transfer efficiency, easy to clear and maintain, and capable of long-term stable operation.

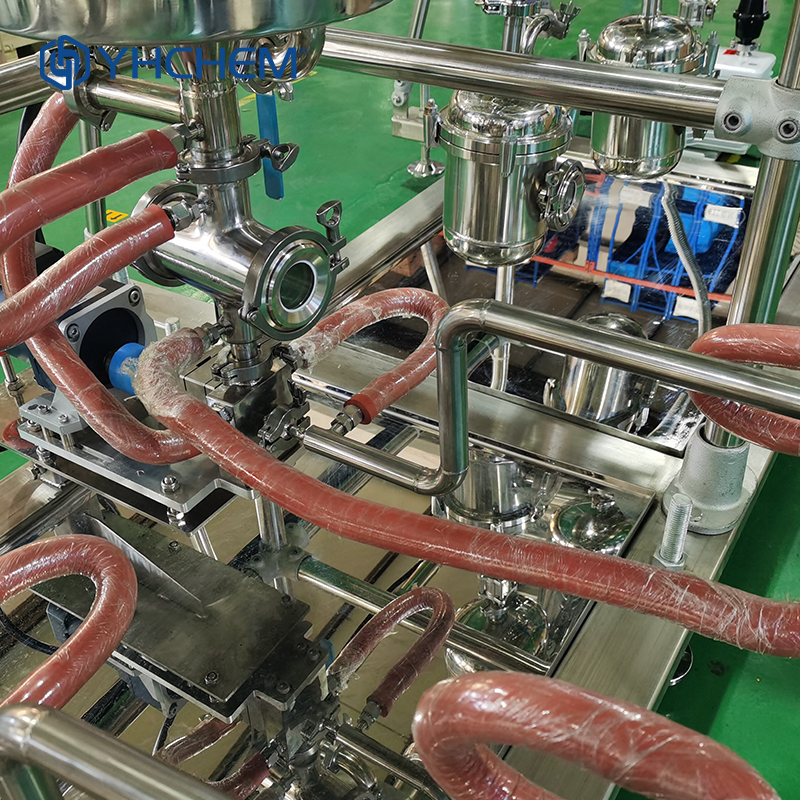

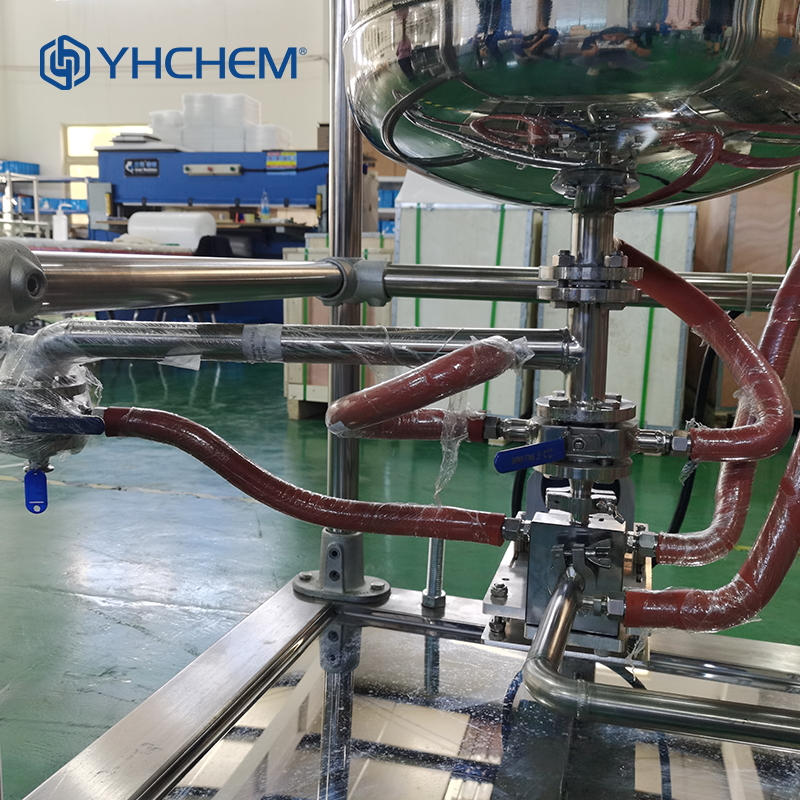

♣2.Unique Full Jacket and Full Insulation Desing

••Jacket design of feed tank, heat-conducting oil preheating and heat preservation function;

Good corrosion resistance, high temperature and pressure resistance, durability,high heat transfer efficiency, easy to clear and maintain, and capable of long-term stable operation.

♣2.Unique Full Jacket and Full Insulation Desing

••Jacket design of feed tank, heat-conducting oil preheating and heat preservation function;

•

•

The outlet jacket design for light and heavy components makes the material flow smoothly;

•

•

Jacket design of automatic feeding and discharging pump head to prevent material blocking from happening;

•

•

The thermal insulation design of the full jacket pipe meets the use conditions of different materials.

♣3.Modular Design flexible Selection

High-precision automatic feeding and discharging pump,the independent magnetic coupling sealing structure.It can be matched with different vacuum units to realize two-stage or multi-stage pump connection

♣4.Safe and Reliable

Brand frequency conversion and deceleration motor, safe and reliable operation, can work continuously for a long time; the entire system can be equipped with explosion-proof configuration.

♣5.EASY TO USE

It is easy to operate, use and maintain. Users can easily adjust system parameters to meet different molecular distillatior requirements

♣3.Modular Design flexible Selection

High-precision automatic feeding and discharging pump,the independent magnetic coupling sealing structure.It can be matched with different vacuum units to realize two-stage or multi-stage pump connection

♣4.Safe and Reliable

Brand frequency conversion and deceleration motor, safe and reliable operation, can work continuously for a long time; the entire system can be equipped with explosion-proof configuration.

♣5.EASY TO USE

It is easy to operate, use and maintain. Users can easily adjust system parameters to meet different molecular distillatior requirements

Application Fields

♣1.Chemical lndustry

used for separation and purification of various chemical substances such as polymers,synthetic resins, synthetic fibers solvents,etc.

♣2.Pharmaceutical Industry

used for separation, purification, and concentration of various medicines and biological products.

♣3.Food and Beverage Industry

used for beverage concentration, dairy products, juice, syrup and spice extraction, etc.

♣4.Petroleum and Chemical lndustry

used for processing and purification of oil products such as gasoline, diesel, kerosene. lubricants, etc.

used for separation and purification of various chemical substances such as polymers,synthetic resins, synthetic fibers solvents,etc.

♣2.Pharmaceutical Industry

used for separation, purification, and concentration of various medicines and biological products.

♣3.Food and Beverage Industry

used for beverage concentration, dairy products, juice, syrup and spice extraction, etc.

♣4.Petroleum and Chemical lndustry

used for processing and purification of oil products such as gasoline, diesel, kerosene. lubricants, etc.

Support Customisation

Can be customized according to customer's requirement.

♣1.Multi-stage design to meet the requirements of different material extraction processes and purity.

♣1.Multi-stage design to meet the requirements of different material extraction processes and purity.

Two-stage, three-stage and more stages designs can be customized.

♣2.Integrated vacuum and cooling and heating systems to reduce floor space.

♣3.PLC control system (optional), real-time monitoring of equipment operating status, dynamic adjustment of equipment parameters, storage of operating data, and analysis of application results.

♣2.Integrated vacuum and cooling and heating systems to reduce floor space.

♣3.PLC control system (optional), real-time monitoring of equipment operating status, dynamic adjustment of equipment parameters, storage of operating data, and analysis of application results.

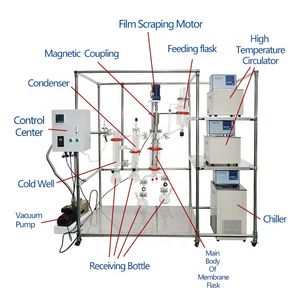

Product Structure

♣Motor

♣Main evaporator

♣Feeding tank

♣Gear pump

♣Cotrol system

♣Cold trap

♣Receiving tank

♣Main evaporator

♣Feeding tank

♣Gear pump

♣Cotrol system

♣Cold trap

♣Receiving tank

Supported Equipment

♣1.CONTROL SYSTEM

Frequency

Frequency

Optional automatic control system (PLC unit)

♣2.DISTILLER

YHCHEM's latest design brings better evaporation efficiency.

Optional jacket discharge module,suitable for high boiling point viscosity materials

♣3.VACUUM SERIES

Bipolar rotary vane vacuum oil

Optional Roots pump

♣2.DISTILLER

YHCHEM's latest design brings better evaporation efficiency.

Optional jacket discharge module,suitable for high boiling point viscosity materials

♣3.VACUUM SERIES

Bipolar rotary vane vacuum oil

Optional Roots pump

Optional diffusion pump

Optional molecular pump

♣4.CONSTANT TEMPERATURE SYSTEM

Heating circulator

♣4.CONSTANT TEMPERATURE SYSTEM

Heating circulator

Cooling circulator

Heating/cooling circulator

♣5.FEEDING & DICHARGING

Optional jacketed glass feeding tank and receiving tank (Customizable volume).

Automatic gear pump feeding and discharging system.

♣5.FEEDING & DICHARGING

Optional jacketed glass feeding tank and receiving tank (Customizable volume).

Automatic gear pump feeding and discharging system.

Product Series

♣1.WIPE FILM MOLECULAR DISTILLATION SYSTEM (

BOROSILICATE GLASS

)

♣2. THIN FILM MOLECULAR DISTILLATION SYSTEM (BOROSILICATE GLASS)

♣3.THIN FILM EVAPORATION SYSTEM (STAINLESS STEEL)

♣4.SHORT PATH DISTILLATION KIT

♣2. THIN FILM MOLECULAR DISTILLATION SYSTEM (BOROSILICATE GLASS)

♣3.THIN FILM EVAPORATION SYSTEM (STAINLESS STEEL)

♣4.SHORT PATH DISTILLATION KIT

Product Details

♣1.The connecting pipe is sealed with fluororubber or tetrafluororubber material to meet the use of materials of different properties

♣2.The design of sight glass such as the feeding tank and the discharging portis convenient to observe the state of the material.

♣3.The feeding and discharging are both controlled with high precisionby gear pumps, providing a stable feeding speed.

♣4.The control box supports numerical display control of light and heavy component pipeline insulation, displays scraper motor speed adjustment, and is equipped with emergency stop and power indicator.

♣2.The design of sight glass such as the feeding tank and the discharging portis convenient to observe the state of the material.

♣3.The feeding and discharging are both controlled with high precisionby gear pumps, providing a stable feeding speed.

♣4.The control box supports numerical display control of light and heavy component pipeline insulation, displays scraper motor speed adjustment, and is equipped with emergency stop and power indicator.

Hot Searches