- Product Details

- {{item.text}}

Quick Details

-

Application:

-

auto industry, petroleum industry, medical, food industry

-

Hardness:

-

20-90 shore A

-

Temperature:

-

--60 ~350

-

Sample:

-

Provide free samples

-

Feature:

-

resistance to oil, weather, abrasion, solvent

-

OUTSIDE PACKING:

-

Inner packing with plastic bags and box, outer packing with carton

-

MOQ:

-

1000pcs

-

Shape:

-

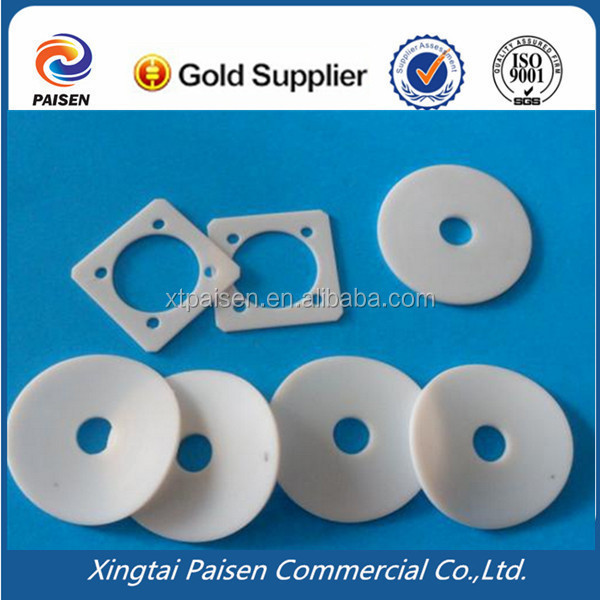

As per customer's design

Quick Details

-

Place of Origin:

-

Hebei, China

-

Standard or Nonstandard:

-

Standard

-

OEM:

-

OEM is welcomed

-

Application:

-

auto industry, petroleum industry, medical, food industry

-

Hardness:

-

20-90 shore A

-

Temperature:

-

--60 ~350

-

Sample:

-

Provide free samples

-

Feature:

-

resistance to oil, weather, abrasion, solvent

-

OUTSIDE PACKING:

-

Inner packing with plastic bags and box, outer packing with carton

-

MOQ:

-

1000pcs

-

Shape:

-

As per customer's design

anti high temperature PTFE teflon seal o ring/gasket/washer for axle/shaft/transformer

An O-ring , also known as a packing , or a toric joint , is a mechanical gasket in the shape of a torus ; it is a loop of elastomer with a round cross-section , designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface.

The O-ring may be used in static applications or in dynamic applications where there is relative motion between the parts and the O-ring. Dynamic examples include rotating pump shafts and hydraulic cylinder pistons.

O-rings are one of the most common seals used in machine design because they are inexpensive, easy to make, reliable, and have simple mounting requirements. They can seal tens of megapascals (thousands of psi ) of pressure.

Function of the rubber o ring

O-Rings are used in sanitary pipeline systems for the Auto, Machinery, Food, Dairy, Beverage, Pharmaceutical and Bio-Tech industries. Rubber Fab offers a full line of AS568 dash numbers, metric, and specialty o-ring sizes that are manufactured using EPDM, NBR, FKM Fluoroelastomer, Buna-N, PTFE, Silicone and so on.

The o-rings used in cylinder, pump, railcars, truck, washing machine, instrument and meter, mine equipment, pipeline, household appliances, automobile, steamboat, industrial electrical equipment, building door& window, construction machinery, construction bridges and tunnel.

1. mechanical sealing, pressure vessel ,gas compressor, reaction vessel ,heat

exchanger, boiler, filter and so on.

2.it can be used for all kinds of electronic products in a wide range ,such as camera, mobile phone, printer, computer.

3. Used for automobile windows and doors, etc...

4.Silk screen printing, spray coating, laser etching, back-lighted, hard/epoxy coating keypads.

|

Product Name |

Rubber o ring for sealing |

|

Materials |

NBR, HNBR, EPDM, SILICONE, VITON, FLS, FFPM, PTFE |

|

Temperature |

NBR(-40~120°C),FFKM(-20~320°C) Viton(-20~200°C),Silicone (-70~220°C) EPDM(-50~150°C),PU(-40~90°C) |

|

Feature |

Resistance to high pressure, oil, weather, abrasion, solvent, high temperature, abrasion resistant, aging resistant, insulation, acid and alkaline resistant |

|

Cerfiticate |

ISO 9001:2008 |

|

Hardness |

30-90 shores A |

|

Color |

Red, Black, White, blue, green, Clear, etc |

|

Size |

Any size, Customized/standard and nonstandard |

|

Sample time |

If instock, within 3 days after payment |

|

Delivery time |

7-15 days by express after payment 10-20 days by ship |

|

Shipping |

Small quantity: UPS/FeDex/DHL express Large quantity: by Air/Sea |

|

Customized |

OEM & ODM are welcomed |

|

packing |

plastic bag&carton box or according to your requirements |

|

Application |

chemical industry, petroleum industry, medical technique, food industry, sewage-disposal industry, steel industry, semi-conduct industry and so on. |

|

Viton O ring |

Silicone O ring |

NBR O ring |

HNBR O ring |

EPDM O ring |

NR O ring |

Peoprene O ring |

|

|

Abbreviation |

FKM |

silicone |

NBR |

HNBR |

EPDM |

NR |

Neoprene |

|

Durometer(shoreA) |

60-90 |

30-90 |

20-95 |

50-90 |

30-90 |

20-90 |

20-95 |

|

Tensile(P.S.I) |

500-2000 |

200-1500 |

200-3000 |

2600 |

500-2500 |

500-3500 |

500-3000 |

|

Elongation(Max.%) |

300 |

700 |

600 |

530 |

600 |

700 |

600 |

|

Compression set |

good |

Good |

Good |

Excellent |

Good |

Excellent |

Good |

|

Resilience-Rebound |

Fair |

Good |

Good |

Excellent |

Good |

Excellent |

Excellent |

|

Abrasion Resistance |

Good |

Fair to poor |

Excellent |

Excellent |

Good |

Excellent |

Excellent |

|

Tear Resistance |

Good |

poor |

Good |

Excellent |

Fair |

Excellent |

Good |

|

Solvent Resistant |

Excellent |

poor |

Good to excellent |

Good |

Poor |

Poor |

Fair |

|

Oil Resistant |

Excellent |

Fair to poor |

Good to excellent |

Excellent |

Poor |

Poor |

Fair |