The combustion temperature, combustion atmosphere and combustion time can be adjusted and controlled flexibly to better adapt to the technological requirements.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

18.5-125KW

-

Dimension(L*W*H):

-

Depends on model

-

Weight:

-

47.5 kg

-

Product name:

-

Zinc oxide kiln

-

Type:

-

Rotary type

-

Installation:

-

Engineer's Guide

-

Manufactory:

-

Henan Hongke

-

Fuel:

-

Gas, oil or coal

-

Calcination material:

-

Flue ash, iron slag, ,blast furnace ash,

-

Factory visit:

-

Welcome warmly

-

Material:

-

Q235

-

Advantage:

-

Low Consumption

-

Main Equipment:

-

Rorary kiln,dust filter,rotary cooler

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Honke

-

Voltage:

-

220v/380v

-

Power:

-

18.5-125KW

-

Dimension(L*W*H):

-

Depends on model

-

Weight:

-

47.5 kg

-

Product name:

-

Zinc oxide kiln

-

Type:

-

Rotary type

-

Installation:

-

Engineer's Guide

-

Manufactory:

-

Henan Hongke

-

Fuel:

-

Gas, oil or coal

-

Calcination material:

-

Flue ash, iron slag, ,blast furnace ash,

-

Factory visit:

-

Welcome warmly

-

Material:

-

Q235

-

Advantage:

-

Low Consumption

-

Main Equipment:

-

Rorary kiln,dust filter,rotary cooler

Energy-saving Recycling Zinc Oxide Equipment from Electrical Arc Furnace Zinc Cylindrical Rotary Kiln Zinc Oxide Kiln

Product Overview

Zinc oxide

kiln calcines zinc-containing flue ash, iron slag, non-ferrous smelter containing zinc flue ash,

blast furnace ash, zinc ash and other zinc containing raw materials (zinc content 8-20%, lead 2-8%, arsenic less than 1%, sulfur less than 1.5%,silver is greater than 20g/t).

Zinc oxide (Zn45-60%,Pb5-8%) was obtained by oxidation roasting and reducing zinc vapor and hot air oxidation at high temperature (1000-1100 ℃) in rotary kiln. R

esidue

calcined in rotary kilns (lead 0.3-0.5%) ,zinc 1-2%, iron 20-30%) can be sold in cement plants or magnetic separation iron.

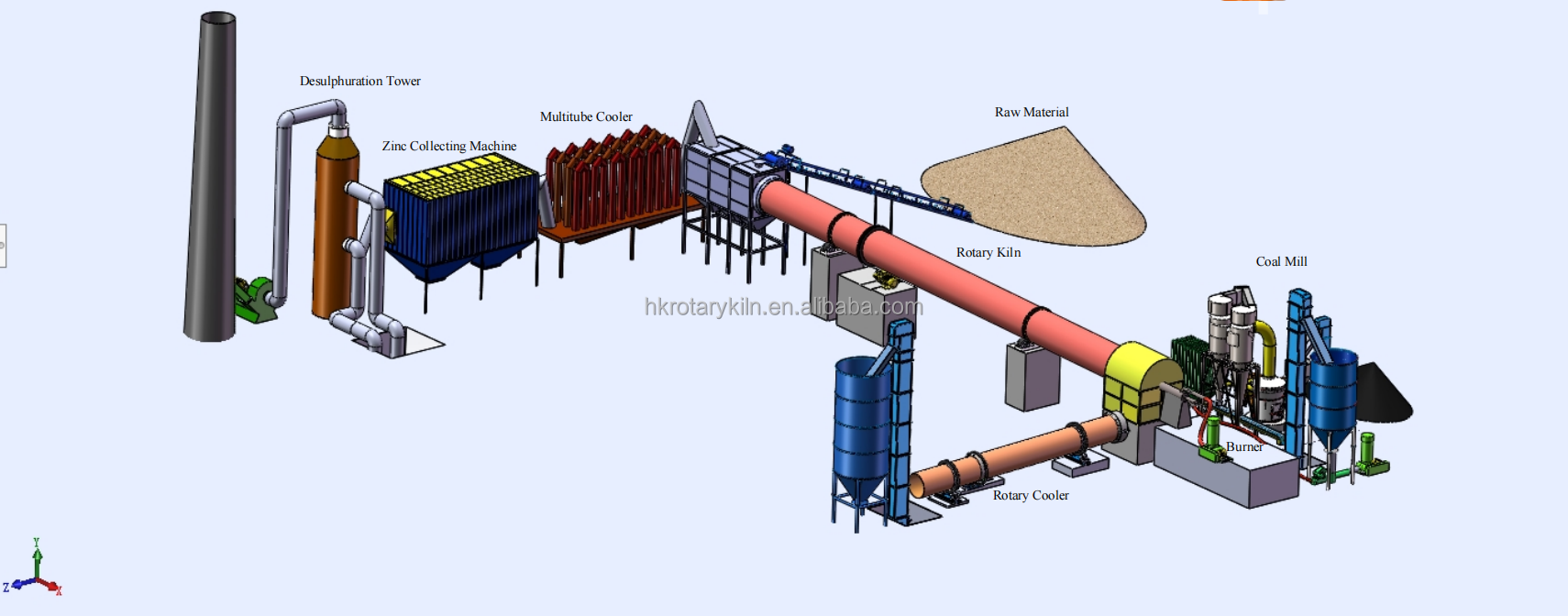

PROCESS PROCESS

The high temperature (750 ℃) delivered by the rotary kiln and the gases containing various partial oxides and dust are separated for the first time in the settling chamber to dissipate heat and continue to oxidize;

The specific gravity of this dust is larger than that of oxide through the oxide and some dust brought by the cooled gas (300-400 ℃).

The second separation and cooling (temperature < 160 ℃) are achieved through more than 11 groups of multi-tube coolers. About 160°and with very strong oxide and dust gas are carried out by pulse method, dust is separated and cooled, dust falls into ash hopper, gas enters the desulfurization tower, and the temperature drops below 60 ℃.

The second separation and cooling (temperature < 160 ℃) are achieved through more than 11 groups of multi-tube coolers. About 160°and with very strong oxide and dust gas are carried out by pulse method, dust is separated and cooled, dust falls into ash hopper, gas enters the desulfurization tower, and the temperature drops below 60 ℃.

To bring the The sulfur dioxide gas and other gases entering the desulfurization tower flow upward from the bottom of the tower, while the lye flows from top to bottom in a three-stage mist flow, and moves upward through the change of direction of entry and deceleration of the third stage hollow ball, The final sulfur content of the discharged gas should not exceed 400 mg.

After neutralizing with acid and base, calcium sulfite precipitate will be produced. The water slag will be separated and caged by filter press, and calcium sulfite will be removed as waste residue.

PRODUCT SPECIFICATIONS

|

Specification Model

(m) |

The size of the kiln

|

|

|

Yield

(t/h) |

Speed

(r/min) |

Electrical power (kw)

|

Weight

(t) |

Remarks

|

||

|

|

Diameter

(m) |

Length

(m) |

Gradient

(%) |

|

|

|

|

|

||

|

φ1.4×33

|

1.4

|

33

|

3

|

0.9-1.3

|

0.39-3.96

|

18.5

|

47.5

|

----

|

||

|

φ1.6×36

|

1.6

|

36

|

4

|

1.2-1.9

|

0.26-2.63

|

22

|

52

|

----

|

||

|

φ1.8×45

|

1.8

|

45

|

4

|

1.9-2.4

|

0.16-1.62

|

30

|

78.2

|

----

|

||

|

φ1.9×39

|

1.9

|

39

|

4

|

1.65-3

|

0.29-2.93

|

30

|

77.59

|

----

|

||

|

φ2.0×40

|

2

|

40

|

3

|

2.5-4

|

0.23-2.26

|

37

|

119.1

|

----

|

||

|

φ2.2×45

|

2.2

|

45

|

3.5

|

3.4-5.4

|

0.21-2.44

|

45

|

128.3

|

----

|

||

|

φ2.5×40

|

2.5

|

40

|

3.5

|

9.0-10.5

|

0.44-2.44

|

55

|

149.61

|

----

|

||

|

φ2.5×50

|

2.5

|

50

|

3

|

6.25-7.4

|

0.62-1.86

|

55

|

187.37

|

----

|

||

|

φ2.5×54

|

2.5

|

54

|

3.5

|

6.9-8.5

|

0.48-1.45

|

55

|

196.29

|

----

|

||

|

φ2.7×42

|

2.7

|

42

|

3.5

|

10.0-11.0

|

0.10-1.52

|

55

|

198.5

|

----

|

||

|

φ2.8×44

|

2.8

|

44

|

3.5

|

12.5-13.5

|

0.437-2.18

|

55

|

201.58

|

Preheater kiln

|

||

|

φ3.0×45

|

3

|

45

|

3.5

|

12.8-14.5

|

0.5-2.47

|

75

|

210.94

|

----

|

||

|

φ3.0×48

|

3

|

48

|

3.5

|

25.6-29.3

|

0.6-3.48

|

100

|

237

|

|

||

|

φ3.0×60

|

3

|

60

|

3.5

|

12.3-14.1

|

0.3-2

|

100

|

310

|

----

|

||

|

φ3.2×50

|

3.2

|

50

|

4

|

40.5-42

|

0.6-3

|

125

|

278

|

|

||

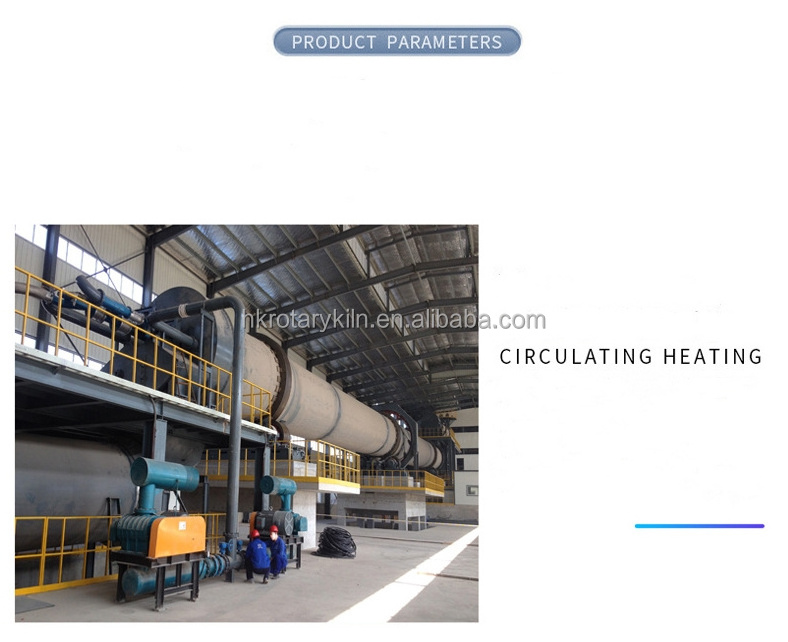

FEATURES AT A GLANCE

Zinc oxide kiln has the advantages of uniform heating of materials, full reaction, good product, good quality, stable and reliable operation of equipment, high adjustability and simple operation and maintenance.

Successful Project

Factory Workshop Pictures

COMPANY PROFILE

Henan Hongke Heavy Machinery Co., Ltd. is located in Henan Province which is the cultural base of the central area of China. We are a mining machinery manufacturing enterprise that integrates scientific research, production and marketing.

We are a high-tech enterprise that specializes in the research and production of rotary kilns, dryers, crushers and so on, such as new type of lime rotary kiln, ceramsite kiln, zinc oxide rotary kiln, sludge rotary kiln, chemical rotary kiln, metallurgical rotary kiln, Raymond mill, ultra-fine mill, large and medium dryer, ball mill, sand mill,stone production line, mineral processing equipment, wood crusher, pellet machine and so on.

From the design, production, installation and debugging, we provide you the entire tracking service.We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

We are a high-tech enterprise that specializes in the research and production of rotary kilns, dryers, crushers and so on, such as new type of lime rotary kiln, ceramsite kiln, zinc oxide rotary kiln, sludge rotary kiln, chemical rotary kiln, metallurgical rotary kiln, Raymond mill, ultra-fine mill, large and medium dryer, ball mill, sand mill,stone production line, mineral processing equipment, wood crusher, pellet machine and so on.

From the design, production, installation and debugging, we provide you the entire tracking service.We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

FAQ

1. What is the minium order quantity?

One set.

2.How long is the warranty period?

One year. Wearing parts are excluded.

3. What is the after-service of your company?

We can provide the customers foudation drawing, installation service, work training as well as other service according to the

customer's requirements.

4.How long is the delivery time?

About 15 days after we receive the payment.

5. What are the payment terms?

T/T, L/C are the best, it can be adjustable according to different situations.

--------------------------------------------------------------------------------------

Kindly Note:

1. Please pay attention to the capacity. It's what you must take into consideration in choosing a suitable machine.

2. Please Inform us the follow figures:

1). Size and content analysis of raw material

2). Capacity ( t/h)

3). Heating Source ( Coal, natural gas or oil)

Upon we got your message we shall give you our favorable offer in short time.

One set.

2.How long is the warranty period?

One year. Wearing parts are excluded.

3. What is the after-service of your company?

We can provide the customers foudation drawing, installation service, work training as well as other service according to the

customer's requirements.

4.How long is the delivery time?

About 15 days after we receive the payment.

5. What are the payment terms?

T/T, L/C are the best, it can be adjustable according to different situations.

--------------------------------------------------------------------------------------

Kindly Note:

1. Please pay attention to the capacity. It's what you must take into consideration in choosing a suitable machine.

2. Please Inform us the follow figures:

1). Size and content analysis of raw material

2). Capacity ( t/h)

3). Heating Source ( Coal, natural gas or oil)

Upon we got your message we shall give you our favorable offer in short time.

Hot Searches