- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Building, Interior Wall Decoration

-

Design Style:

-

Modern

-

Type:

-

Magnesium Oxide Board

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhuchen

-

Model Number:

-

ZC-MB-01

-

Product name:

-

mgo board

-

Raw material:

-

MgO + MgSO4

-

Size:

-

1220*2440/1220*3000mm

-

Thickness:

-

3-20mm

-

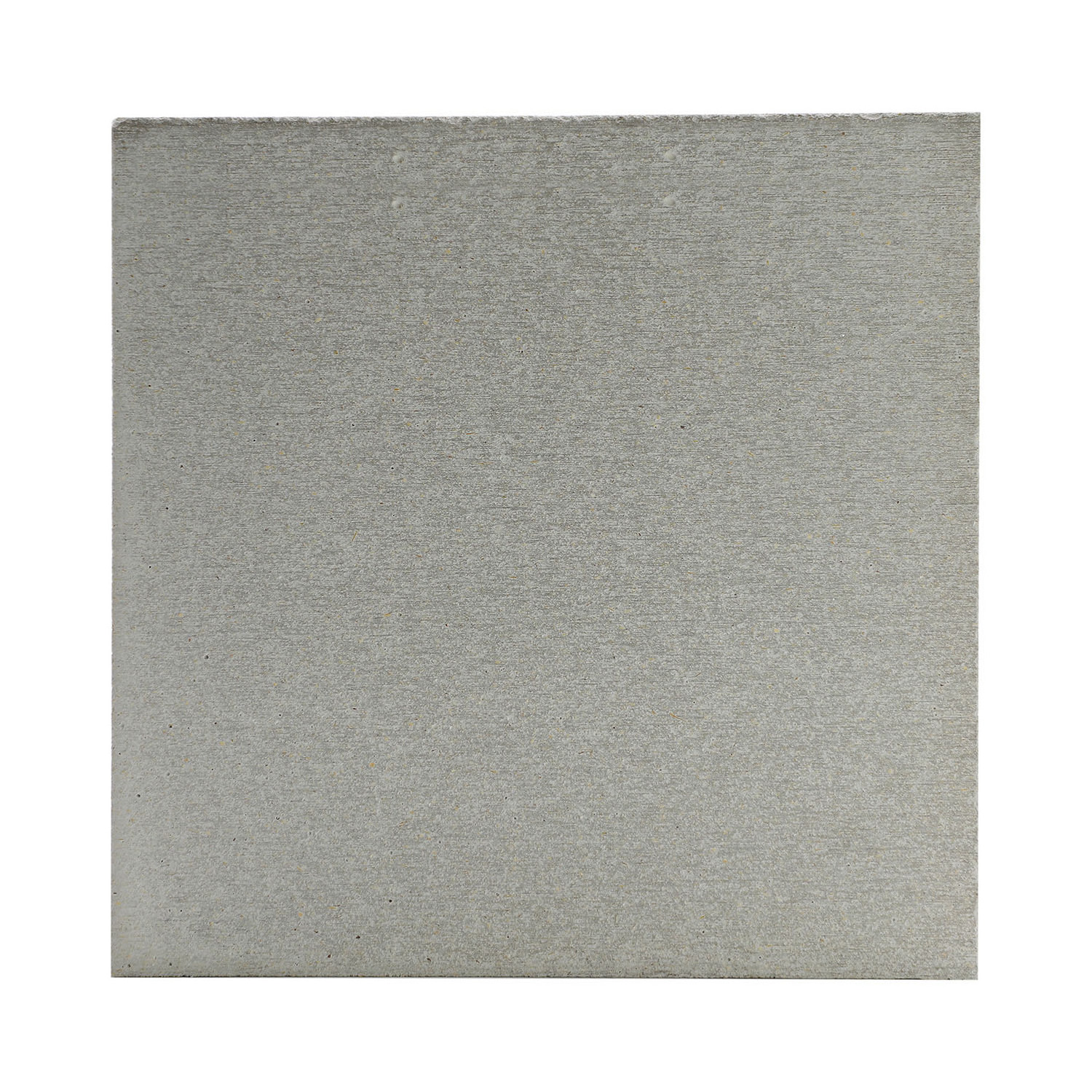

Color:

-

Customized

-

classify:

-

standard board /sanding board

-

Density:

-

0.95-1.1kg/m3

-

Fireproof Grade:

-

Grade A1

-

Key Advantage:

-

Fire Resistant Morre

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Free spare parts, Other

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

-

Application:

-

Building, Interior Wall Decoration

-

Design Style:

-

Modern

-

Type:

-

Magnesium Oxide Board

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhuchen

-

Model Number:

-

ZC-MB-01

-

Product name:

-

mgo board

-

Raw material:

-

MgO + MgSO4

-

Size:

-

1220*2440/1220*3000mm

-

Thickness:

-

3-20mm

-

Color:

-

Customized

-

classify:

-

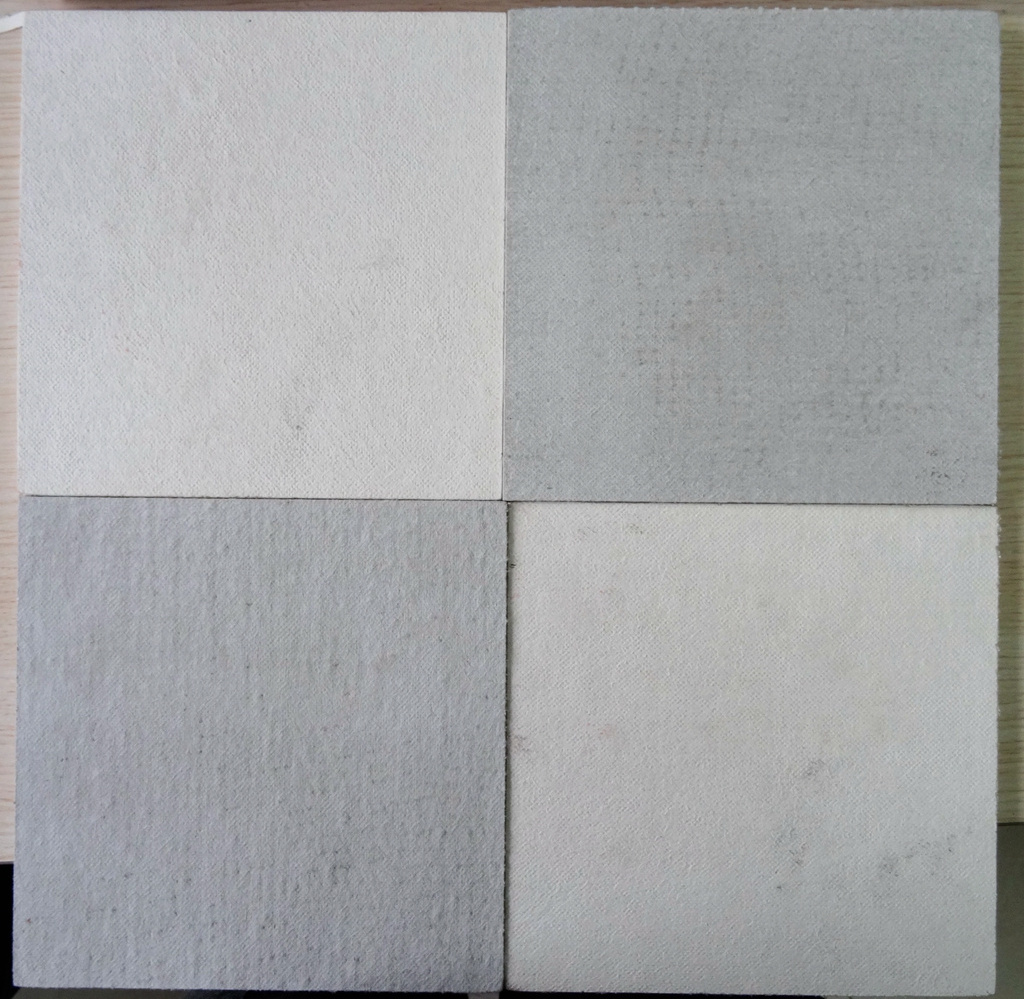

standard board /sanding board

-

Density:

-

0.95-1.1kg/m3

-

Fireproof Grade:

-

Grade A1

-

Key Advantage:

-

Fire Resistant Morre

Product Description

MgO board has outstanding characteristics to make it the ideal building product for your home.

MgO boards have:

• Outstanding

fire

performance

• Insulation against

heat and cold

•

Sound insulation

•

Damp proof

•

Tough

(can do all proper modeling)

• Protected against insects

•

Simple, easy

and swift construction

• Easy to decorate, cut, bore, plane and shear

•

Durable

•

100% Free of harmful substances

(e.g. asbestos)

•

Environmentally friendly

Product Details

|

Width

|

600/900/1200/1220, and special width

|

|

Length

|

Standard is 2400-3050mm, special size should speically customized

|

|

Thickness

|

3-25mm

|

|

Color

|

White; Pink; Purple; Green; Grey; Blue; Black; Brown, etc, we can customize for you

|

|

Edge

|

Square; tapered; T&G; L - shiplap

|

|

Capacity

|

4000 pieces/day

|

|

Type

|

Sanding mgo board; Non-woven mgo board; HPL laminated mgo board; Flooring mgo board

|

Six raw materials for the production of Mgo Board

|

MgO Powder

|

Content of Magnesium ≥ 85% Activity ≥ 60% Content of CaO ≤ 2%

|

|

Magnesium Sulfate

|

Activity ≥ 65% Purity ≥ 99%

|

|

Fiberglass Mesh

|

Main function is to increase the strengh Fiber glass mesh has differents kinds, like high-alkali; Mid-Alkali;Low-Alkali;Alkali-free;alkali-resisting. 99% factories use Mid-Alkali

|

|

Bamboo Fiber

|

Bamboo Fiber has to be sieved first so that choose the right Particle Size; Also, for the humidity of the bamboo fiber, should be less than 15%

|

|

Perlite

|

If the filling materials only use Sawdust, the weight of the board still very heavy, so we need perlite to reduce the weight

|

|

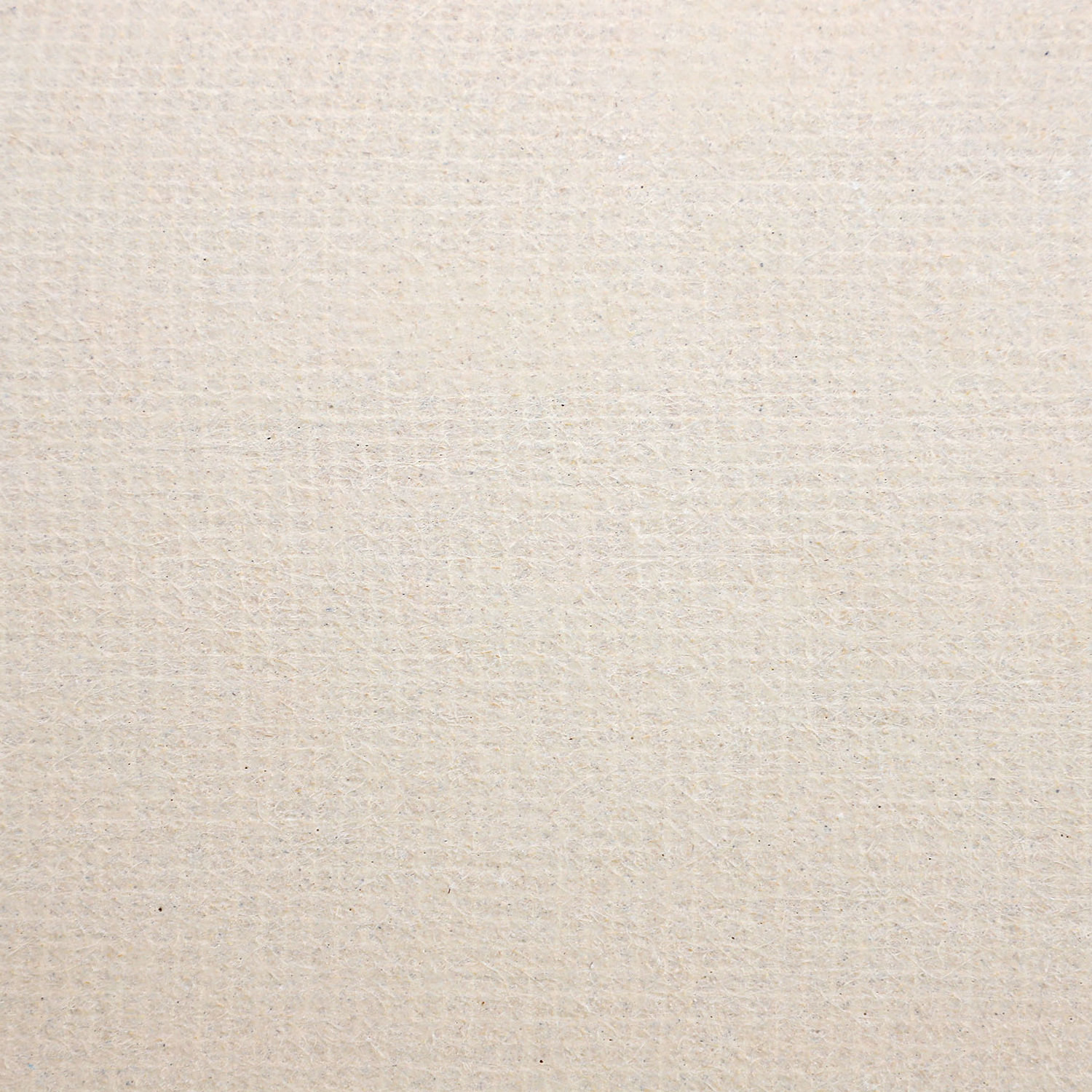

Non-woven Fabric

|

Main function is to make to board looks like more smooth and increase the planarity of the board; But for increase the strength function is very limited

|

Complete Quality Control Process

Before each batch of raw materials into the factory, laboratory test firstly, and make the quality report, If it is qualified after the factory to use. After the production of each batch of boards is completed, we will conduct ampling tests on this batch of boards, and carry out strict testing on the boards from various aspects such as density, strength, hardness etc.to ensure that the pass rate of each batch of boards reaches 99.8 %.

Scientific Proportioning, Accurate Calculation

MgSo4 purity is 99% min and the content of chloride ion is around 0.034%. The formula of pure magnesium sulfate board, which was developed ten years ago, is the most mature formula technology of pure magnesium sulfate board in the market. It has been tested by the market. It is also its own unique formula.

Strict Requirement For Producing MgO Sulphate

1) The activity of MgO powder has to be above 65%

2) The purity of MgO sulfate has to be above 99%

3) Much more strict requirement for temperature and humidity control, usually need to do the third time curing.

Different Types of Mgo Boards

Standard Non-woven Mgo Board

A smooth surface and rough backside.Widely used in construction as SIP surface board.

1. nice fireproof performance

2. nice waterproof performance

3. much stronger than the fiber cement board: 10mm Mgo board stronger than 14mm fiber cement board

3. much stronger than the fiber cement board: 10mm Mgo board stronger than 14mm fiber cement board

Premium Sanding board

Both smooth surface and smooth sanded backside.

1. nice fireproof performance and waterproof performance

2. the thickness tolerance is very small.

3. Easier for deep process: laminated with HPL material, PVC, melamine, etc. as interior decorated wall panel, cladding to the steels.

1. nice fireproof performance and waterproof performance

2. the thickness tolerance is very small.

3. Easier for deep process: laminated with HPL material, PVC, melamine, etc. as interior decorated wall panel, cladding to the steels.

Stronger Mgo Flooring Board

Specially designed for the flooring project need high strength performance.

1. over 6 layers high strength fiberglass mesh.

2. using a very nice glue coated fiberglass mesh in stronger and longer using life.

3. The bending strength could reach 20Mpa of 18mm.

2. using a very nice glue coated fiberglass mesh in stronger and longer using life.

3. The bending strength could reach 20Mpa of 18mm.

Laminated MgO board

1. HPL laminated MgO board

2. Melamine paper laminated MgO board.

3. Using in decoration walls or floors

Fireproof, high strength, waterproof and easy to clean.

3. Using in decoration walls or floors

Fireproof, high strength, waterproof and easy to clean.

Using Applications

Interior Decoration

Its

fireproof performance is A1 grade, water resistance

and high strength, the

10mm MgO board

will be stronger than

14mm fiber cement board.

Floorings

Its specially

customized for Flooring

, and its bending strength could be up to

20MPa.

The backside is sanded and very flat, the tolerance could be

less than 0.02mm.

Structural Insulated Panels

The great advantages of strength and fireproof performance lead the MgO board very suitable for making

SIP panels.

Partition Walls

The MgO Board is very suitable for partition walls, no matter the

steel frame or the wood frame.

About Us

Yurui (shandong) Machinery Co., Ltd.

is a manufacturer of pure sulfate Magnesium Oxide Board, DON’T use any magnesium chloride and totally chloride free.

Our factory is equipped with high automatic machine and mature new technology to make the pure sulfate Magnesium Oxide Board. From the raw materials to the test of the final products, we take care of every single detail. Because we take the quality as our life.

Our Figures

Already

20

year experiences in producing MgO Board.

We are 1st manufacturer of pure sulfate MgO board.

Have 4 production line to focus on different requirements.

Over 50 countries keep supplying and exporting to with reliable quality.

We are 1st manufacturer of pure sulfate MgO board.

Have 4 production line to focus on different requirements.

Over 50 countries keep supplying and exporting to with reliable quality.

Deeply study MgO board and production machinery for 20+years,own top technique.

1. Professional export team:full of experience to handle the export,transportation,files,and documents.

2. Experienced engineer and workers for production: Our general engineers own 18 years experience and professional technology in MGO board field, proficient in the process from No.1 generation MGO board production until the newest MGO board machine design/manufacturing.

3. Equipped with high automatic production line,ensure standard and consistent processing.

4. Strict production procedures and strict QC system and implement.

2. Experienced engineer and workers for production: Our general engineers own 18 years experience and professional technology in MGO board field, proficient in the process from No.1 generation MGO board production until the newest MGO board machine design/manufacturing.

3. Equipped with high automatic production line,ensure standard and consistent processing.

4. Strict production procedures and strict QC system and implement.

Strict Quality Control System

Work together with any third party inspection and factory audit. Whole system in factory from raw materials to finished product, to make sure the product are inspected and qualified.

Before each batch of raw materials into the factory, laboratory test firstly, and make the quality report, If it is qualified after the factory to use.

After the production, we will

conduct sampling tests

on boards, and carry out

strict testing

on the boards from various aspects such as density, strength, hardness etc.to ensure that the pass rate of each batch of boards reaches 99.8 %.

Customization

Rich experience in customization, custom products do not mean that customers give us a specification and we just follow them.

Generally, it is necessary to communicate with customers in depth about the application requirements of products, and at the same time, multiple proofing tests are required to finally form a qualified finished product.

Generally, it is necessary to communicate with customers in depth about the application requirements of products, and at the same time, multiple proofing tests are required to finally form a qualified finished product.

Packing & Shipping

Before Package

Before package, the board will be tested and inspected again by our lab and worker. Each of the board will be cleaned to make sure the board are clean and pick out any defect board.

During Package

We will use film to cover the pallets to avoid any mosiure during the transportation. Use green PET package strapping - Bundle the boards and reinforce the pallets.

FAQ

Q1. How do you pack your boards?

A: Generally, we pack our goods in strong wood pallets.

Q2. What are your terms of payment?

A: T/T 30% as deposit, and 70% against to the BL copy.

Q3. What are your terms of delivery?

A: FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples. If you have special requirements of the products, we also could discuss with our engineers.

Q6. Could you provide samples?

A: Sure, please contact us now.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Warmly welcome you contact me for your questions.

Hot Searches