- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.2-1.0mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOWANN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5800mm*1600mm*1800mm

-

Weight:

-

2000 kg

-

Product Name:

-

Shelf Roll Forming Machine

-

Certificate:

-

CE, ISO

-

Frame Materials:

-

350H steel

-

Diameter:

-

80mm

-

Forming Shaft:

-

Material 45# quenched and tempered

-

Cutting System:

-

Hydraulic Cutting

-

Electric tension:

-

380V 50 Hz 3 Phase or as your requirements

-

Main Engine power:

-

4 KW with cycloidal reducer

-

Hydraulic oil:

-

40# hydraulic oil

-

Material of cutting table:

-

Cr 12 mould steel with quenched treatment

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.2-1.0mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOWANN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5800mm*1600mm*1800mm

-

Weight:

-

2000 kg

-

Product Name:

-

Shelf Roll Forming Machine

-

Certificate:

-

CE, ISO

-

Frame Materials:

-

350H steel

-

Diameter:

-

80mm

-

Forming Shaft:

-

Material 45# quenched and tempered

-

Cutting System:

-

Hydraulic Cutting

-

Electric tension:

-

380V 50 Hz 3 Phase or as your requirements

-

Main Engine power:

-

4 KW with cycloidal reducer

-

Hydraulic oil:

-

40# hydraulic oil

-

Material of cutting table:

-

Cr 12 mould steel with quenched treatment

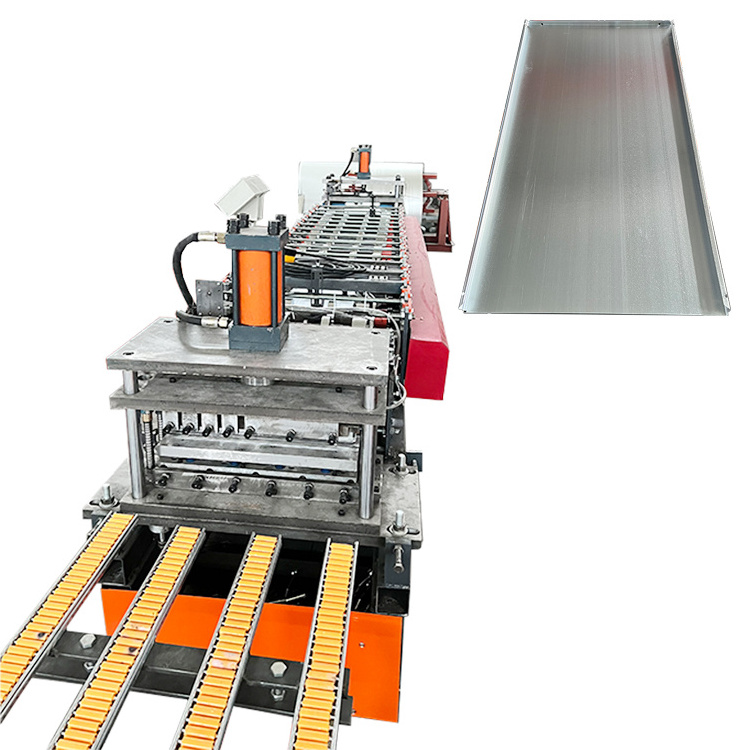

Shelving New Design Double Side Shelf Metal Supermarket Shelf Roll Forming Machine

Product Description

The production line is highly integrated by uncoiling ,leveling,forming,cutting off,punching,receiving and related process. The whole production line is controlled by PCL program .

Operators can select a preset program to run the whole line automatically by using touch screen. The methods of operation include automatic control ,manual control,separate operation and emergency stop .

Technical Specifications of the storage shelf cold roll forming machine

Technical Specifications of the storage shelf cold roll forming machine

Advantages of the storage shelf cold roll forming machine

1. Good quality: We have a professional designer and experienced engineer team and the raw material and accessories we use are good.

2. Good service: we provide the technical support for whole life of our machines.

3. Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4. Easy operation: All machine controlling by PLC computer controlling system.

5. Elegant appearance: Protect the machine from rust and the painted color can be customized

6. Reasonable price: We offer the best price in our industry.

2. Good service: we provide the technical support for whole life of our machines.

3. Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4. Easy operation: All machine controlling by PLC computer controlling system.

5. Elegant appearance: Protect the machine from rust and the painted color can be customized

6. Reasonable price: We offer the best price in our industry.

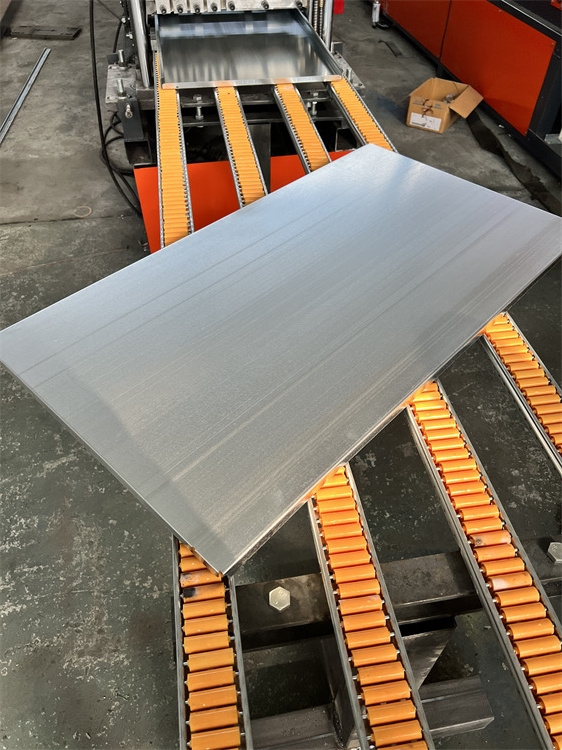

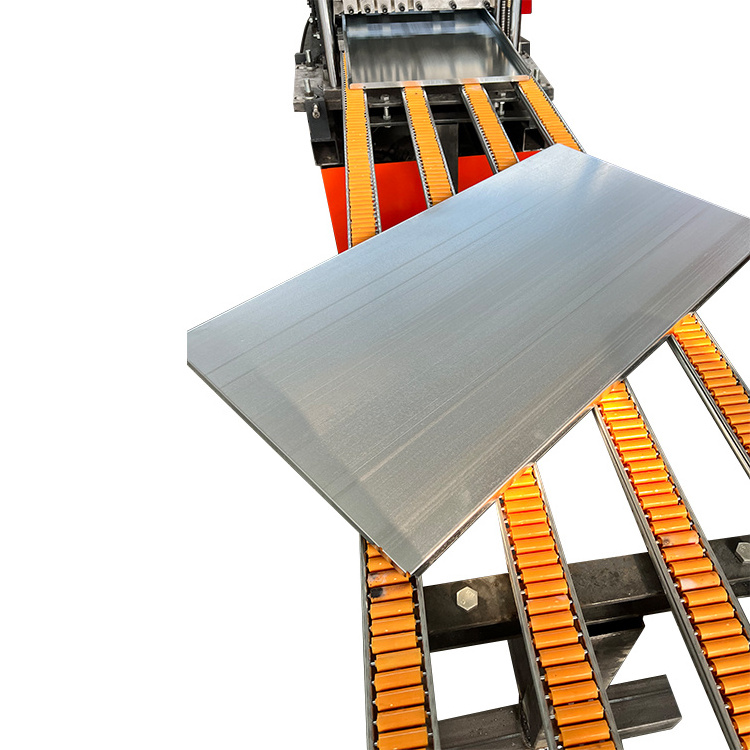

Details Images

Specification

|

Suitable Material

|

Galvanized Steel Coil

|

|

Material Width

|

According to Profile Drawing

|

|

Material Thickness

|

0.8-1.2 mm

|

|

Roll forming speed

|

10-15 m/min (Exclude Punching & Cutting Time)

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Certifications

Hot Searches