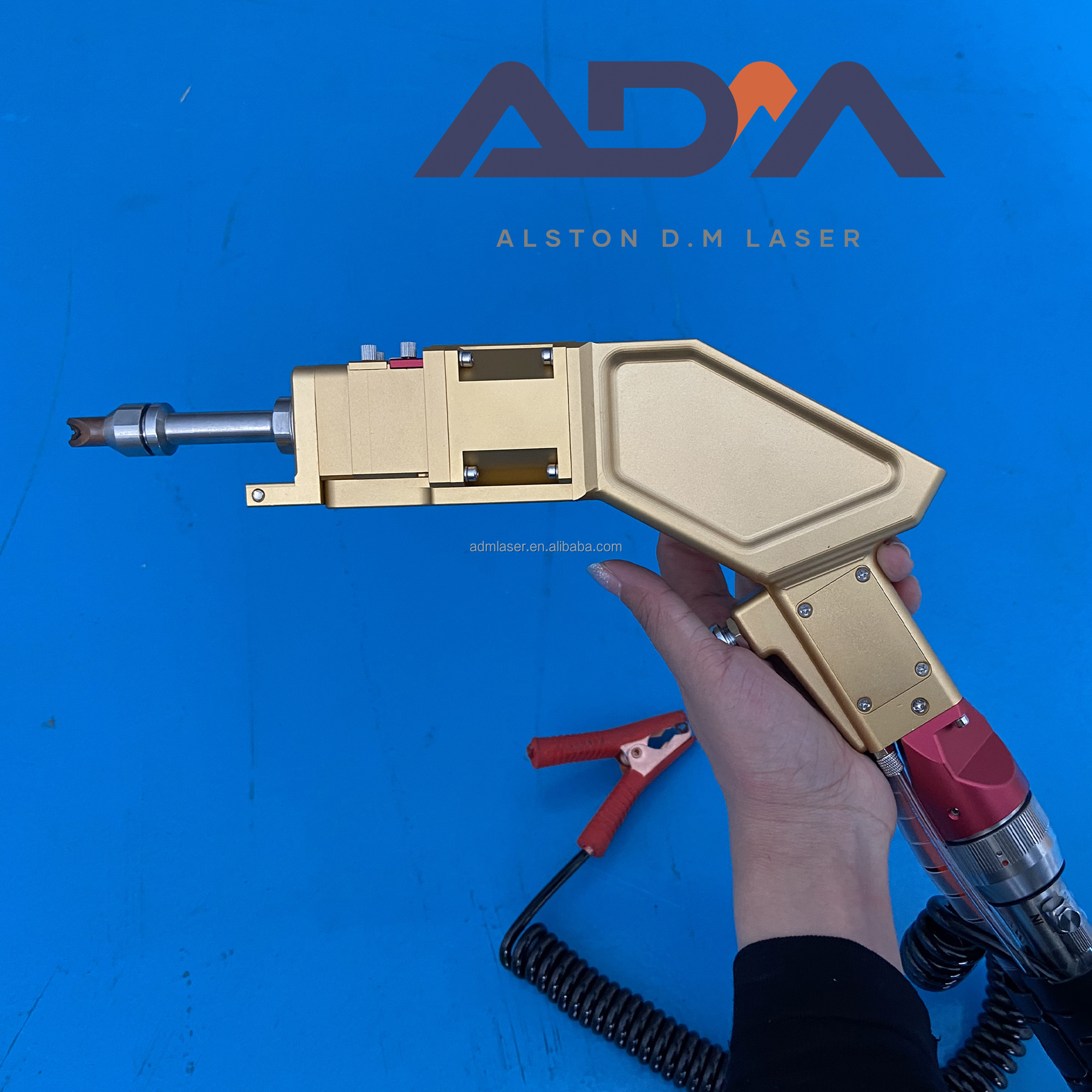

High accurate and easy opreate

Portable handheld welding head is the biggest character of the machine. Instead of the fixed welding head,it offers so much

welding convenience for welding.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ADM

-

Single Pulse Energy:

-

-

-

Pulse Width:

-

1070mm

-

Wavelength:

-

-

-

Focal Spot Diameter:

-

-

-

Dimensions:

-

-

-

Weight (KG):

-

140 KG

-

Marketing Type:

-

New Product 2021

-

Core Components:

-

fiber laser source

-

Cooling Method:

-

Water Cooliing

-

Laser type:

-

Fiber Laser

-

Max laser power:

-

1000W/1500W/2000W

-

Welding depth:

-

0.05 - 4 Mm

-

Power Supply:

-

380V/50/60HZ

-

Laser source:

-

Raycus /Max/IPG

-

Welding speed:

-

0-120mm/s

-

Welding materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Welding Machine )

-

Protective Gas:

-

Nitrogen Gas/air

-

Welding Speed Range:

-

0-120 - Mm/s

Quick Details

-

Max. Output Power:

-

1000/1500/2000

-

Use:

-

fiber laser welding machine

-

Laser Source Brand:

-

Raycus/Max/IPG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ADM

-

Single Pulse Energy:

-

-

-

Pulse Width:

-

1070mm

-

Wavelength:

-

-

-

Focal Spot Diameter:

-

-

-

Dimensions:

-

-

-

Weight (KG):

-

140 KG

-

Marketing Type:

-

New Product 2021

-

Core Components:

-

fiber laser source

-

Cooling Method:

-

Water Cooliing

-

Laser type:

-

Fiber Laser

-

Max laser power:

-

1000W/1500W/2000W

-

Welding depth:

-

0.05 - 4 Mm

-

Power Supply:

-

380V/50/60HZ

-

Laser source:

-

Raycus /Max/IPG

-

Welding speed:

-

0-120mm/s

-

Welding materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Welding Machine )

-

Protective Gas:

-

Nitrogen Gas/air

-

Welding Speed Range:

-

0-120 - Mm/s

Products Description

|

NO.

|

Machine model

|

|

MWG-1000H /MWG-1500H/ MWG-2000H

|

|

|

|||

|

1

|

Max laser power

|

|

1000W 1500W 2000W

|

|

|

|||

|

2

|

Laser source

|

|

Raycus/Max brand from China;IPG brand from Germany

|

|

|

|||

|

3

|

Beam quality

|

|

1.3m²

|

|

|

|||

|

4

|

Laser wavelength

|

|

1080±5nm

|

|

|

|||

|

5

|

Welding head

|

|

ADM brand with QBH

|

|

|

|||

|

5

|

Water chiller

|

|

BY1000;Double temperature dual control

|

|

|

|||

|

6

|

Power required

|

|

380V±10%/50Hz

|

|

|

|||

|

7

|

Power Consumption

|

|

6KW

|

|

|

|||

|

8

|

Fiber optical length

|

|

10m

|

|

|

|||

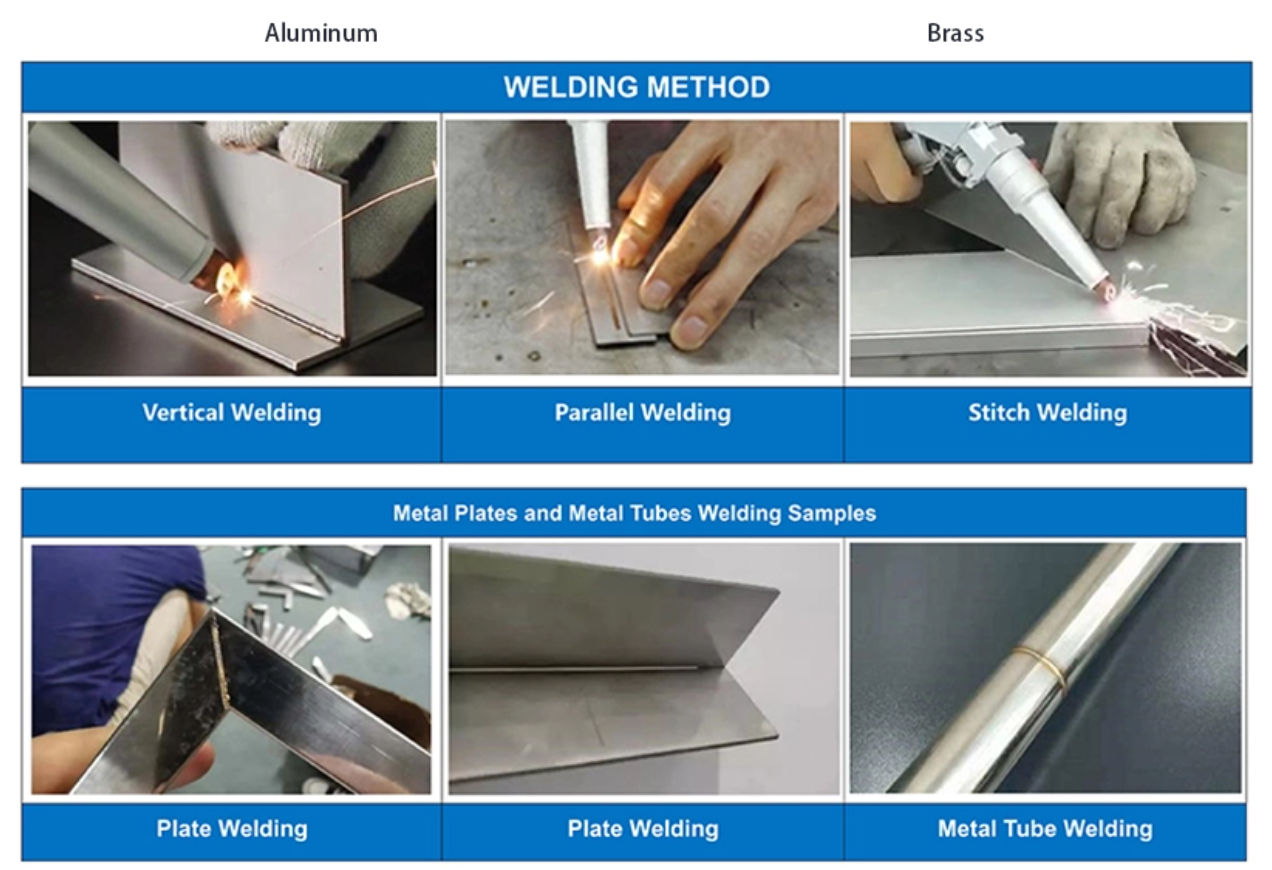

Laser welding is a new type of welding method and one of the important aspects of the application of laser material processing technology. Laser welding is mainly for the welding of thin-walled materials and precision parts. The welding process is of thermal conductivity type, that is, the surface of the workpiece is heated by laser radiation, and the surface heat Diffusing into the interior through heat conduction, and by controlling parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece is melted to form a specific molten pool. It can realize spot welding, butt welding, stitch welding, sealing welding, etc., with high aspect ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, smooth and beautiful weld, no need to handle or just need to be processed after welding Simple processing, high weld quality, no air holes, precise control, small focus spot, high positioning accuracy

Hand-Held welding head

Auto Filler

wire-thickness :

0.6 – 0.8mm-1.0mm-1.2mm-1.5mm

0.6 – 0.8mm-1.0mm-1.2mm-1.5mm

Laser source and Chiller

Adopting famous brands (Raycus, JPT, MAX, IPG and other brands), the photoelectric conversion rate is greatly improved, laser

power is enhanced, has better welding effect, can according to the needs of customers with different configurations to meet

customer needs.

power is enhanced, has better welding effect, can according to the needs of customers with different configurations to meet

customer needs.

One of the biggest convenience of the machine is the inside water chiller. It saves a lot of the machine's dimension.It is

constant temperature industrial type.

constant temperature industrial type.

Our Advantages

|

|

Tig Welders

|

Laser Welders

|

|

Heat input

|

Very high heat

|

Very low calories

|

|

Deformation

|

Easy to deform

|

No deformation

|

|

Welding spot

|

Large welding spot

|

Fine welding spot, adjustable spot

|

|

Exterior

|

Unsightly, need polishing

|

Smooth and beautiful, no need to sand

|

|

Perforation

|

Easy to pierce

|

Not easy to perforate, can be controlled

|

|

Protective gas

|

Need argon

|

Need argon

|

|

Precision

|

general

|

Precision

|

|

Processing time

|

Long time

|

Short time

|

|

Safety

|

Ultraviolet light, radiation

|

Radiation-free

|

The handheld laser welding machine replaces the traditional fixed optical path with a new generation of handheld welding torch, which is flexible and convenient, and overcomes the limitation of the worktable space. The size of the workpiece

When it is not uniform, automatic welding is not possible.

Mainly for large work pieces, fixed positions such as inner right angles, outer right angles, and flat welds.

During welding, the heat-affected area is small, the deformation is small, the welding depth is large, and the welding is firm. It is a new welding process for long-distance welding of large work pieces.

Laser welding can weld difficult-to-access parts and perform non-contact long-distance welding with great flexibility.

When it is not uniform, automatic welding is not possible.

Mainly for large work pieces, fixed positions such as inner right angles, outer right angles, and flat welds.

During welding, the heat-affected area is small, the deformation is small, the welding depth is large, and the welding is firm. It is a new welding process for long-distance welding of large work pieces.

Laser welding can weld difficult-to-access parts and perform non-contact long-distance welding with great flexibility.

Features

1. The hand-held welding gun replaces the previous fixed optical path, which is more flexible and convenient, realizes long-distance laser welding, and overcomes the limitation of the workbench stroke space;

2. The hand-held welding head is light and flexible, and the operation is convenient and simple, which can meet the welding of various angles and positions;

3. Infrared positioning is used for welding head position verification and position verification during welding. The welding position is more accurate and the welding seam is more beautiful;

4. The laser welding depth is large and the welding is firm;

5. It is not easy to deform, easy to be polished, and solves the problems of weld penetration, weld bead, welding quality and so on when using argon arc welding;

6. It is also suitable for various complex welding seams and spot welding of various devices.

Application

1. Laser welding of sheet metal, chassis and water tank.

2. All kinds of hardware and lighting laser welding machine

3. Laser welding of door and window frames

4. Laser sealing welding of kitchen, bathroom and wash basin hardware

5. Laser welding of billboards and advertising characters

Suitable for most metals such as stainless steel, titanium, water-plated plate, iron sheet, aluminum copper and other materials.

|

1kw welding ability

|

|

|

|

|||

|

No.

|

Material

|

Depth of fusion

|

Penetration thickness

|

|||

|

1

|

Stainless Steel

|

≤4mm

|

≤3mm

|

|||

|

2

|

Mild steel/Iron

|

≤4mm

|

≤3mm

|

|||

|

3

|

Galvanized sheet

|

≤3mm

|

≤2mm

|

|||

|

4

|

Aluminum/brass

|

≤2mm

|

≤1mm

|

|||

|

1.5kw welding ability

|

|

|

|

|||

|

No.

|

Material

|

Depth of fusion

|

Penetration thickness

|

|||

|

1

|

Stainless Steel

|

≤5mm

|

≤4mm

|

|||

|

2

|

Mild steel/Iron

|

≤5mm

|

≤4mm

|

|||

|

3

|

Galvanized sheet

|

≤4mm

|

≤3mm

|

|||

|

4

|

Aluminum/brass

|

≤3mm

|

≤2mm

|

|||

|

2kw welding ability

|

|

|

|

|||

|

No.

|

Material

|

Depth of fusion

|

Penetration thickness

|

|||

|

1

|

Stainless Steel

|

≤6mm

|

≤5mm

|

|||

|

2

|

Mild steel/Iron

|

≤6mm

|

≤5mm

|

|||

|

3

|

Galvanized sheet

|

≤5mm

|

≤4mm

|

|||

|

4

|

Aluminum/brass

|

≤4mm

|

≤3mm

|

|||

Equipment installation and after-sales

Hot Searches