- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

200*100*60 mm, 240*115*90 mm, 400*200*200 mm, 240*115*52 mm

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

crunmach

-

Voltage:

-

220V or 380V

-

Dimension(L*W*H):

-

4000*3500*2300mm

-

Weight (KG):

-

3500 kg

-

After-sales Service Provided:

-

Video Technical Support

-

Raw material:

-

Conrete

-

Product Name:

-

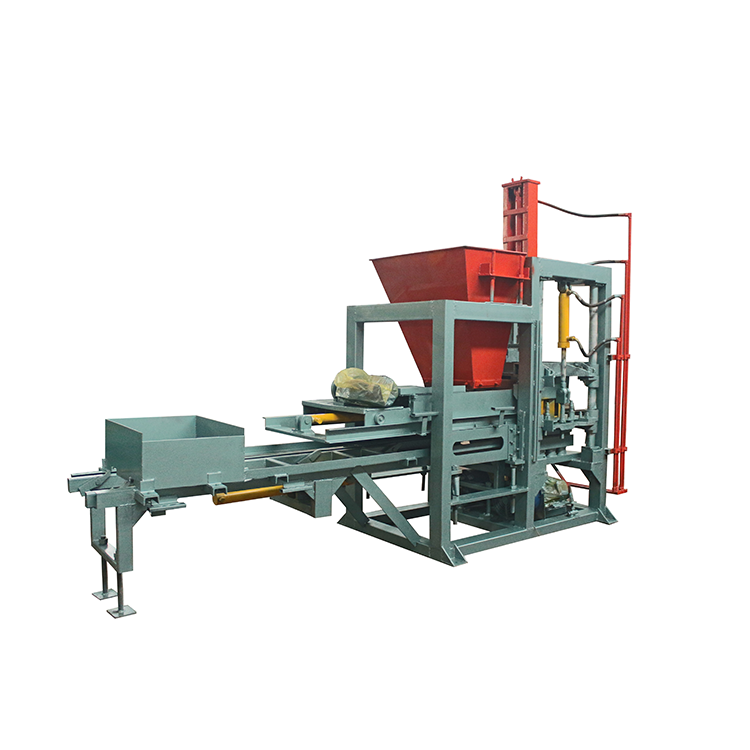

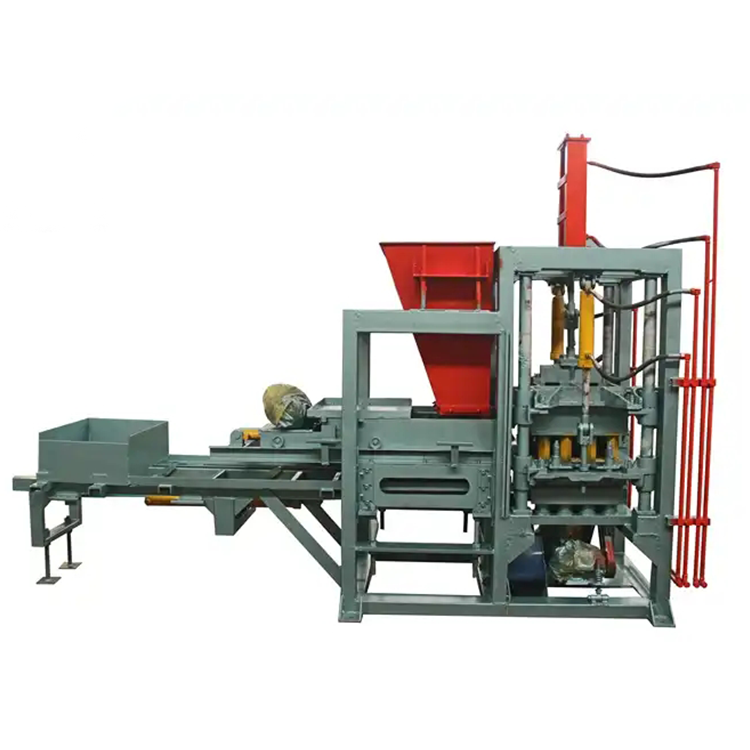

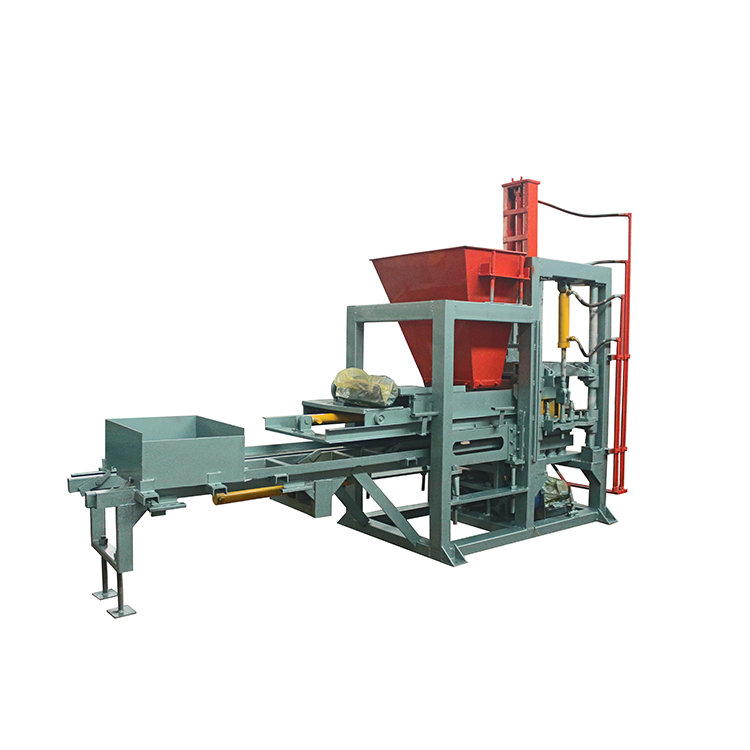

QTY3-35B

-

Keywords:

-

Automatic Cement Block Moulding Machine

-

Color:

-

Customer's Demand

-

Advantage:

-

High Efficiency

-

Pallet size:

-

680*535*30mm

-

Power:

-

21.85kw

-

Pcs/mould:

-

4 Pcs (400*200*200mm )

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

720 pcs/8hours, 4800 pcs/8hours, 1800 pcs/8hours, 2160 pcs/8hours

-

Brick size:

-

200*100*60 mm, 240*115*90 mm, 400*200*200 mm, 240*115*52 mm

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

crunmach

-

Voltage:

-

220V or 380V

-

Dimension(L*W*H):

-

4000*3500*2300mm

-

Weight (KG):

-

3500 kg

-

After-sales Service Provided:

-

Video Technical Support

-

Raw material:

-

Conrete

-

Product Name:

-

QTY3-35B

-

Keywords:

-

Automatic Cement Block Moulding Machine

-

Color:

-

Customer's Demand

-

Advantage:

-

High Efficiency

-

Pallet size:

-

680*535*30mm

-

Power:

-

21.85kw

-

Pcs/mould:

-

4 Pcs (400*200*200mm )

Product Overview

The hydraulic molding machine

Hydraulic block molding machine is the use of industrial waste: stone powder, coal ash, coal gangue, slag, smelting slag and all kinds of tailing slag as raw materials for the production of new building materials brick machine equipment, it is environmentally friendly, energy-saving, able to make the waste recycling. Hydraulic block molding machine, including the upper part of the upper template with compaction mechanism, the lower part of the lower template with demolding mechanism, vibration effect is good, low noise, small mechanical loss, while the use of double crank pressure device, not only compaction effect is good, but also the energy consumption of power is small, the strength of the block is high.

Technical characteristics

1.The hydraulic molding machine is more environmentally friendly and energy efficient.

2.The low cost brick making machine block is made of high-precision, high-strength castings and special welding technology and materials,with good steel, vibration resistance and long life.

3.The hydraulic pressing pill brick making machine has a short molding cycle, high production efficiency, high density and strength of the block mass, and accurate dimensions.

2.The low cost brick making machine block is made of high-precision, high-strength castings and special welding technology and materials,with good steel, vibration resistance and long life.

3.The hydraulic pressing pill brick making machine has a short molding cycle, high production efficiency, high density and strength of the block mass, and accurate dimensions.

Mold

PRODUCT SPECIFICATIONS

|

The main technical parameter

|

|

|

||

|

No

|

Item

|

Data

|

||

|

1

|

Power

|

15.7KW

|

||

|

2

|

Dimension(L*W*H)

|

4000*3500*2300mm

|

||

|

3

|

Pallet size

|

680*535*30mm

|

||

|

4

|

Molding cycle

|

20-30s

|

||

|

5

|

Total weight

|

3500kg

|

||

Raw Material

Brick making machine 3-35B is the use of slag, slag, fly ash, stone powder, sand, stone, cement, etc. as raw materials.

Main brick types

Finished Product Display

Model QYT3-35B multi-function hydraulic molding machine is specialized in producing building blocks, such as standard bricks,hollow bricks and other concrete products.

Packing and Shipping

Our warm team

Henan Changrun Machinery Co., Ltd. is located in Zhengzhou, Henan Province, whose main business covers fixed hollow block molding machine, road hydraulic molding machine, automatic block molding machine, automatic hydraulic block molding machine and so on. We have advanced processing equipment, exquisite professional technology and rich manufacturing experience.

FAQ

Q 1: What kind of blocks can be produced?

A 1: Hollow brick, standard brick.

A 1: Hollow brick, standard brick.

Q 2: Can you guarantee the quality?

A 2: Yes, our equipments are strictly tested before leaving

the factory.

the factory.

Q 3: Do you have operation manual?

A 3: Yes, we will send you the operation manual after you purchase the machine.

Q

4: How long is the warranty period?

4: How long is the warranty period?

A 4: 1 year.

Hot Searches