- Product Details

- {{item.text}}

Quick Details

-

Power:

-

9KW

-

Dimension(L*W*H):

-

3.2*2.2*1.35M

-

Weight:

-

1500KGS

-

Product name:

-

cutting machine

-

Cutting materials:

-

nature leather geniune leather Uneven leather

-

Cutting speed:

-

0-1500mm/s

-

Cutting Depth:

-

0-50mm/s

-

Cutting Accuracy:

-

0-0.1mm

-

Media Fixture Method:

-

Vacuum System

-

Pump Power:

-

5.5KW/7.5KW/9KW

-

Required date files:

-

DXF,AI,PLT

-

Interface:

-

USB/LAN

-

Power supply:

-

AC220V/50HZ,AC380V/50HZ,60HZ Three phase

-

Certification:

-

CE

Quick Details

-

Voltage:

-

220V,380V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YZ

-

Power:

-

9KW

-

Dimension(L*W*H):

-

3.2*2.2*1.35M

-

Weight:

-

1500KGS

-

Product name:

-

cutting machine

-

Cutting materials:

-

nature leather geniune leather Uneven leather

-

Cutting speed:

-

0-1500mm/s

-

Cutting Depth:

-

0-50mm/s

-

Cutting Accuracy:

-

0-0.1mm

-

Media Fixture Method:

-

Vacuum System

-

Pump Power:

-

5.5KW/7.5KW/9KW

-

Required date files:

-

DXF,AI,PLT

-

Interface:

-

USB/LAN

-

Power supply:

-

AC220V/50HZ,AC380V/50HZ,60HZ Three phase

-

Certification:

-

CE

Product Description

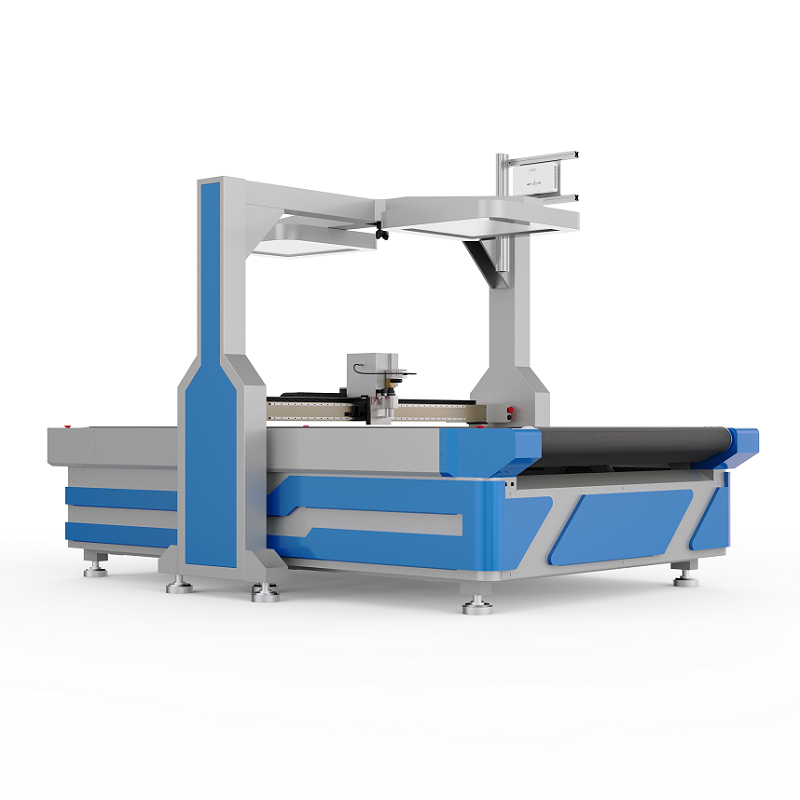

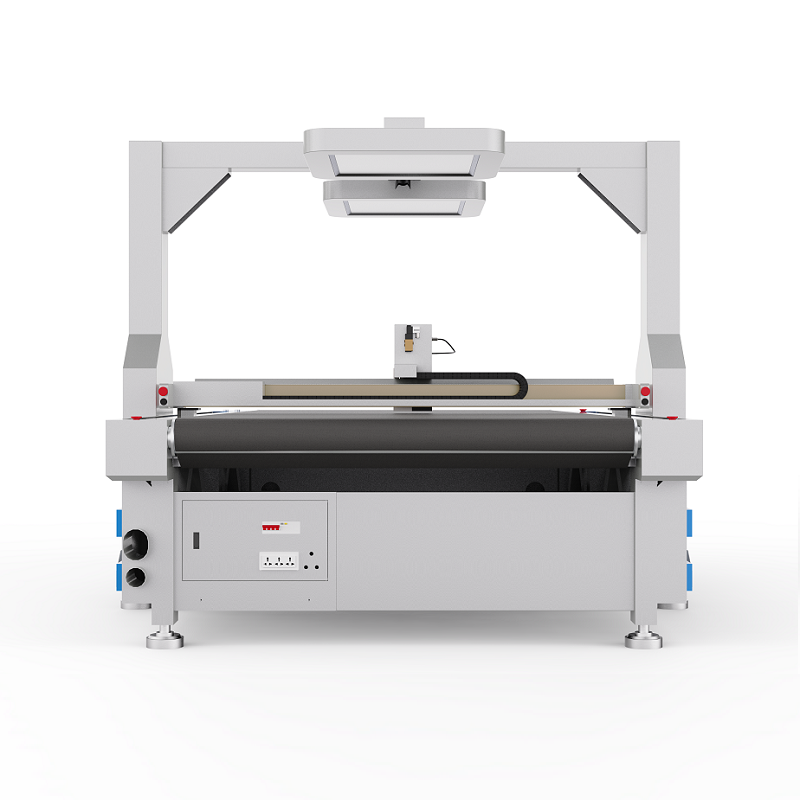

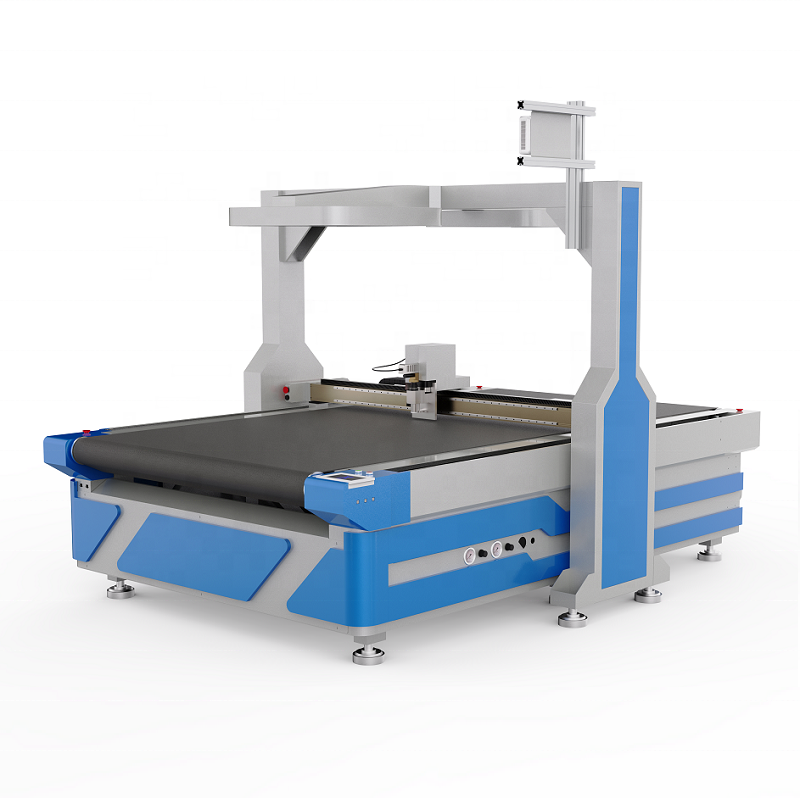

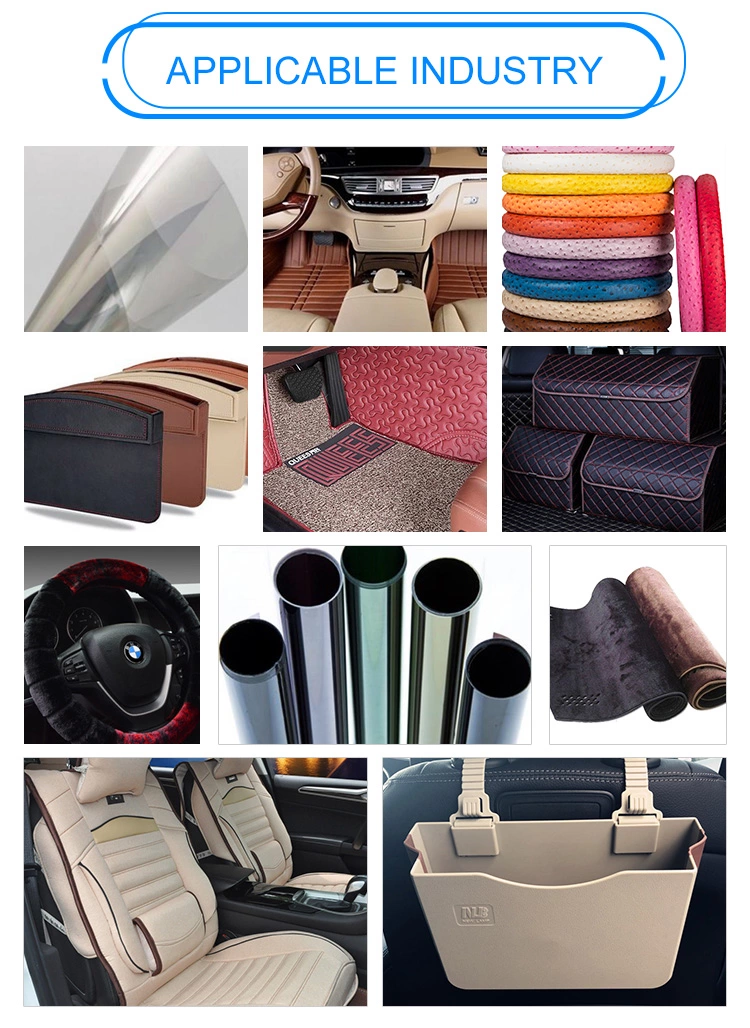

What is CNC oscillating knife cutter?

CNC Oscillating Knife Cutter is a type of CNC cutting machine which is used for high-precision cutting of heavier flexible and semi-rigid materials.

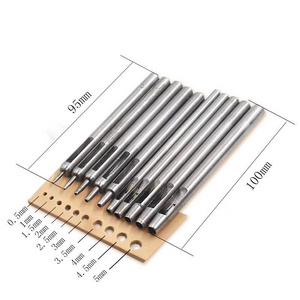

CNC oscillating knife cutting machine is carried on the multi-tool cutting head–Vibration knife, Oblique knife, Circular knife,

Punching knife, Milling knife,Punch roller and Marking pen. CCD camera and Projector are optional for more precise cutting.

CNC Oscillating Knife Cutter is also called CNC Oscillating Knife Cutting Machine, Oscillating Knife Cutting Machine. CNC

Oscillating Knife Cutter is used for cutting Leather, Gasket, PP, PE, EVA, PTFE, ETFE, Carpet, Carton, Wood, MDF, PVC, Acrylic, Carboard, Rubber, Corrugated box, Foam,Leather strip, Composites,

Cardboard, Corrugated board, Honeycomb paper, Plastic film, Fiber paper, Plastic box, Rebound rubber, Rubber cloth, etc.

CNC Oscillating Knife Cutter is widely used in Sign and Graphics, Digital Printing, Packaging, Automotive, Recreational boat,Exhibits and Fixtures, Sign Making,Gasket Materials, Arts and Crafts and other industries.

CNC Oscillating Knife Cutter is a type of CNC cutting machine which is used for high-precision cutting of heavier flexible and semi-rigid materials.

CNC oscillating knife cutting machine is carried on the multi-tool cutting head–Vibration knife, Oblique knife, Circular knife,

Punching knife, Milling knife,Punch roller and Marking pen. CCD camera and Projector are optional for more precise cutting.

CNC Oscillating Knife Cutter is also called CNC Oscillating Knife Cutting Machine, Oscillating Knife Cutting Machine. CNC

Oscillating Knife Cutter is used for cutting Leather, Gasket, PP, PE, EVA, PTFE, ETFE, Carpet, Carton, Wood, MDF, PVC, Acrylic, Carboard, Rubber, Corrugated box, Foam,Leather strip, Composites,

Cardboard, Corrugated board, Honeycomb paper, Plastic film, Fiber paper, Plastic box, Rebound rubber, Rubber cloth, etc.

CNC Oscillating Knife Cutter is widely used in Sign and Graphics, Digital Printing, Packaging, Automotive, Recreational boat,Exhibits and Fixtures, Sign Making,Gasket Materials, Arts and Crafts and other industries.

Specification

|

modle

|

Y1625 CP Plus

|

|

working size

|

1600*2500mm

|

|

max.cutting thickness

|

0-50mm

|

|

Cutting material

|

nature leather , ariitificial leather , leather insole , upper leather , saddle leather , synthetic leather , sole materials etc

|

|

cutting type

|

electrical oscillating cutting tool

drive rotary cutting tool pneumatic oscillating cutting tool |

|

working table

|

section vacuum-cast aluminum vacuum flatbed table

|

|

max.cutting speed

|

0-1500mm/s

|

|

motion system

|

digital servo motor & driver

|

|

repeat location accuracy

|

0.01mm

|

|

voltage

|

ac220v/50hz ac380v/50hz 60hz

|

|

media fixture method

|

section vacuum system

|

|

pupm power

|

5.5kw/7.5kw/9kw/11kw

|

|

operating environment

|

temperature 0-40 humidity 20%-80%RH

|

|

software

|

yizhou CAD

|

|

format support

|

AI/DXF/DWG/JPG/BMP/PLT/DST

|

|

interface

|

USB/LAN/Serial Port

|

Samples

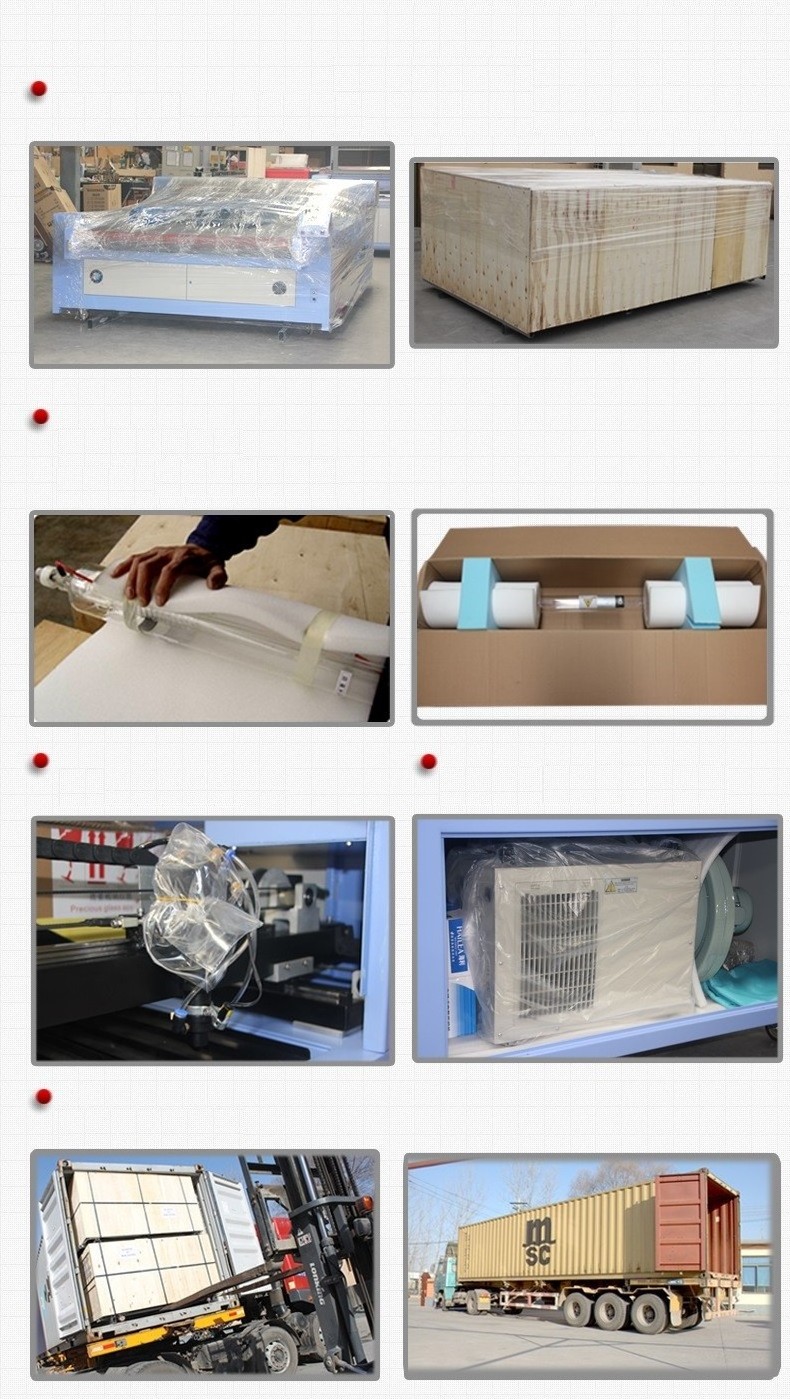

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

About US

Certifications

our service

FAQ

1. Are you a trading company or a factory?

We are manufacturers.

2.When can we arrange shipment?

We usually arrange shipment within 15 days after getting deposit,

but customized machines should be more than 25 days.

We are manufacturers.

2.When can we arrange shipment?

We usually arrange shipment within 15 days after getting deposit,

but customized machines should be more than 25 days.

3. Do you provide equipment operation training after sale?

Yes. We can send professional engineers to the working site for equipment installation, adjustment, and

operation training. All of our engineers have passport.

4. Can you customize the machine according to my request?

Yes. We have experienced engineers and technical team, can provide personalized service company Good working environment, the company regularly attend exhibitions, improve the company's ability, strengthen communication and

learning, and provide good services for customers

Yes. We can send professional engineers to the working site for equipment installation, adjustment, and

operation training. All of our engineers have passport.

4. Can you customize the machine according to my request?

Yes. We have experienced engineers and technical team, can provide personalized service company Good working environment, the company regularly attend exhibitions, improve the company's ability, strengthen communication and

learning, and provide good services for customers

Hot Searches