NE-A series High Negative Pressure (HNP) type welding fume extractor adopts the advanced filter technology. It provides the perfect solution for the fume of welding, cutting, grinding and professionally design for collecting the welding fume. So the HNP welding fume extractor provides services for the customers of purifying the fume and dust.

Before welding fume dust goes into the welder's breathing zone, the HNP fume purifier can collect at the weld source.

The filter cartridge further collects the hazardous submicron particles on the surface of nanofiber membrane to avoid circulatory blowing to factory air.

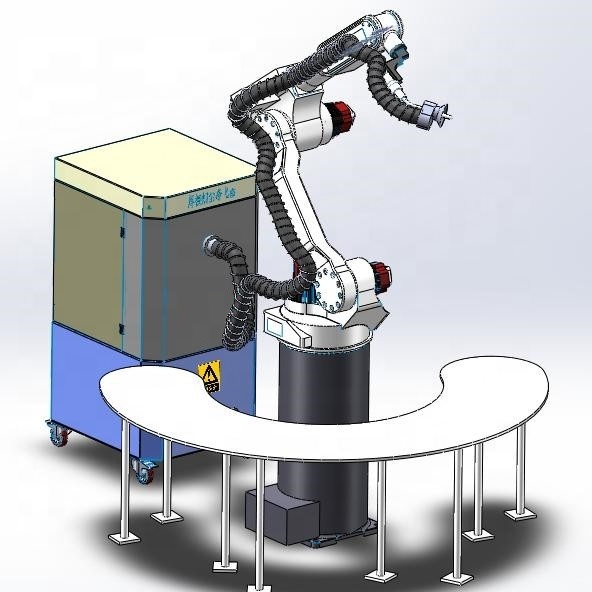

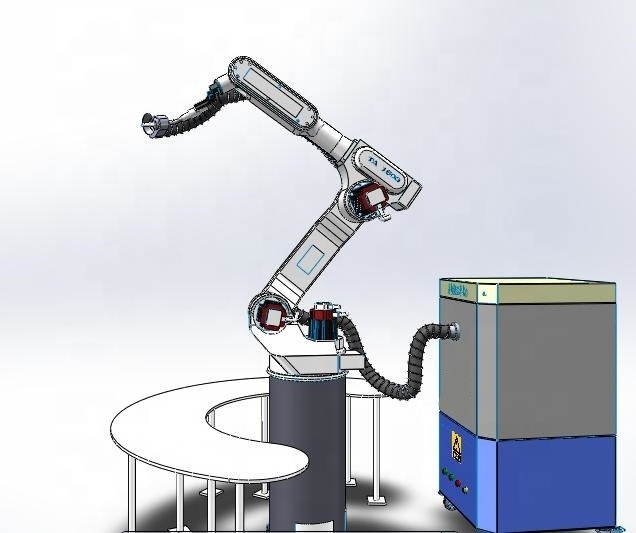

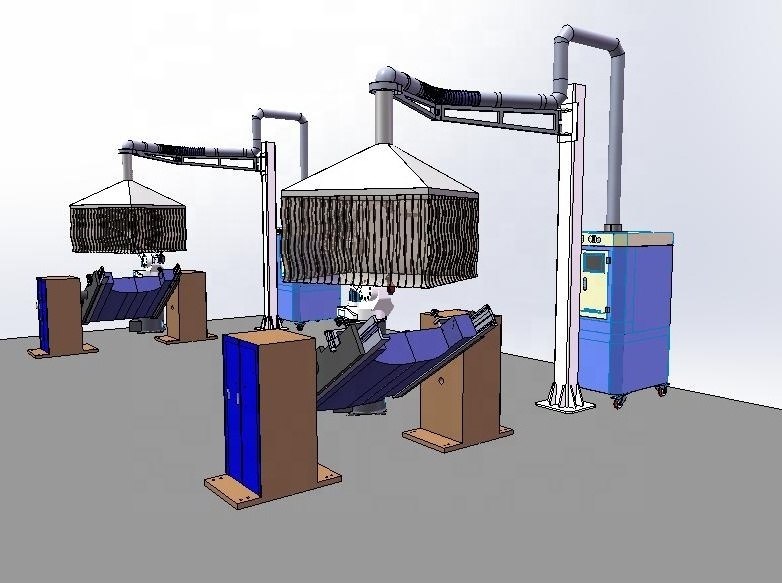

For matching factory different location installation requirement, the HNP welding fume extractor can match multi kinds collection tools to use.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

650*550*1250MM

-

Weight:

-

180 kg

-

Product:

-

High Negative Pressure Industrial Robot Vacuum Cleaner

-

Application:

-

Dust removal

-

Filter Material:

-

PTFE Pleated Cartridge Filter

-

Filter clean type:

-

Pulse Jet Cleaning

-

Color:

-

Standard withe + blue or customized

-

Power:

-

1.1kw;1.5kw;2.2kw;3.0kw

-

Exhaust volume:

-

1200-3600m3/h

-

Filtration efficiency:

-

99.9%

-

Voltage:

-

380V/50Hz or according to customer local condition

Quick Details

-

Minimum Particle Size:

-

0.3

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Qingdao DEER

-

Dimension(L*W*H):

-

650*550*1250MM

-

Weight:

-

180 kg

-

Product:

-

High Negative Pressure Industrial Robot Vacuum Cleaner

-

Application:

-

Dust removal

-

Filter Material:

-

PTFE Pleated Cartridge Filter

-

Filter clean type:

-

Pulse Jet Cleaning

-

Color:

-

Standard withe + blue or customized

-

Power:

-

1.1kw;1.5kw;2.2kw;3.0kw

-

Exhaust volume:

-

1200-3600m3/h

-

Filtration efficiency:

-

99.9%

-

Voltage:

-

380V/50Hz or according to customer local condition

Product Description

TECHNICAL PARAMETER

DER-GE-A series High negative pressure robot welding dust collector

Product introduction

Working Principle

The fan under negative pressure, the air with fume though pipe from air inlet to dust room, the air flow speed drops rapidly, and

the big and heavy particles fume precipitates to the ash hopper, and the fine fume following the airflow is against outside

surface of the filter barrel, the cleaned air is flowing into clean room and discharged from the outlet after noise elimination.

When the internal and external pressure difference of the filter barrel arrives the set value, the electromagnetic pulse valve

opens and at the same time blows the dust to filter barrel, after dust blowing, the pressure difference will be smaller, the dust

collector continues to maintain dust collection status.

the big and heavy particles fume precipitates to the ash hopper, and the fine fume following the airflow is against outside

surface of the filter barrel, the cleaned air is flowing into clean room and discharged from the outlet after noise elimination.

When the internal and external pressure difference of the filter barrel arrives the set value, the electromagnetic pulse valve

opens and at the same time blows the dust to filter barrel, after dust blowing, the pressure difference will be smaller, the dust

collector continues to maintain dust collection status.

Product characteristics

■ Energy conservation environment protection type air fan with compact structure,

Strong absorption power, big air volume, high efficiency, low noise.

■ The filter barrel vertically installed, even filtering surface, good dust cleaning effect, automatic pulse control.

■ Submicron filter barrel with high filtration efficiency, variety of material can be selected by different fume and dust, changeable cycle length.

■ Collection and dust removal for single fume and dust source.

■ Multi air absorption suites can be matched.

Application field:

Purifying the fume and dust of different welding, polishing, cutting, grinding etc. and recycling the rare metals and precious material.

Application Place:

Gas suction welding gun

Grinding fittings

Welding gun head

|

MODEL

|

POWER(KW)

|

AIRFLOW(M3/H)

|

High Negative Pressure

|

DIMENSION(MM)

|

||||

|

DER-GE-A160

|

1.5

|

210

|

23000pa

|

550*550*1150

|

||||

|

DER-GE-A190

|

3.0

|

300

|

32000pa

|

620*620*1150

|

||||

|

EXTRACTION ARM:ONE OR TWO EXTRACTION ARM(Diameter:75mm,Length:10m)

|

|

|

|

|

||||

TECHNICAL PARAMETER

DER-AE SERIES WELDING FUME EXTRACTOR

I Application Area

DER-AE movable Dust & Fume Extraction Machine is used for the purifying of fume and

dust generated from welding, polishing, cutting, grinding and other processes, also for

the recycling of rare metals and precious material. It can purify small metal particles

which are harmful to human body and suspended in the air in large amount with features

of high efficiency of purifying, low noise, agile use, covering small area, etc.

It is suited for electric arc welding, CO2 shielded welding, MAG welding, carbon arc

gouging welding, gas molten cutting, special welding and other workplaces where

generate fume and dust.

III Equipment Advantage

1:Adopt turbine fan and motors, anti-overload circuit which can prevent

motor from burned-out. With the features of high safety, stable performance.

2:Using built-in central electric control mode, simple structure and easy operation.

3: Pulse blowback type automatic dust cleaning: filter core adopts all-round

automatically rotating counter blowing dust cleaning which makes filter dust cleaning

more thoroughly and clean and can always guarantee the extraction machine with a

constant volume of air absorption; Air compressor parts is high-pressure hose

connection with bottom high-pressure air input. It can guarantee the machine always

in good condition. (It can be designed as automatic or manual control according to

user's demand.)

4: Filter drum adopts materials imported from USA with long service life and can absorb

more than 0.3 μm dust particles. It has very good filtering effect to wet and stickydust.

5:Use the universal absorption arm with 360 degrees activity range, which can absorb

fume and dust from the generation place and greatly improve the dust collection rate

to ensure the working person’s health.

6:It adopts three ways of protective measures for fire hazards and big grain slag inside

the machine, which makes the machine more secure and reliable operation and

longer life.

7:Clean air is exhausted from grille air vents evenly and the noise is reduced to a

minimum.

8:Accompanied by specialized new Korean type caster wheel with brake, which is

convenient for equipment movement and positioning.

9:Photoelectric control open and shut down, high efficiency and energy saving,

cantilever mask with illumination device (optional).

10.The consumable material in the machine is with stable performance and easy to

change.

|

MODEL

|

POWER(KW)

|

AIRFLOW(M3/H)

|

VOLTAGE(CUSTOM MADE)

|

DIMENSION(MM)

|

||||

|

DER-AE1200

|

1.1

|

1200

|

220V/50HZ/1PH

|

650*650*1250

|

||||

|

DER-AE1500

|

1.5

|

1500

|

380V/50HZ/3PH

|

650*650*1250

|

||||

|

DER-AE2400

|

2.2

|

2400

|

150V/60HZ/1PH

|

650*650*1250

|

||||

|

DER-AE3600

|

3.0

|

3600

|

220V/60HZ/1PH

|

5650*650*1200

|

||||

|

WITH AUNTOMATIC BACK BLOWING SYSTEM

|

|

|

|

|

||||

|

EXTRACTION ARM:ONE OR TWO EXTRACTION ARM

|

|

|

|

|

||||

Spare parts:

CARTRIDGE FILTER PVC HOSE EXTRACTION ARM

TECHNICAL PARAMETER

DER-DE SERIES WELDING FUME EXTRACTOR

Product structure characteristics

DER-DE type

■ Filter unit-- The pre-filter layer, the main filter layer and the chemical filter layer 3 parts to consist.

The pre-filtration layer can adsorb relatively big particles in the airflow to avoid the earlier blockage of the main filter layer.

The main filter layer is HEPA filter cartridge, vertical installed.

The filtration efficiency of high efficiency filter material for filtration of 0.3 micron particles is 99.9%,

and chemical filter cartridge is generally activated carbon layer, which can effectively adsorb the odor and harmful gas in the airflow, so that the indoor air can be discharged to meet the standard.

■ Pulse cleaning (optional)-- The pulse control system can be cleaned by hand or timing automatically clean the filter barrel.

|

MODEL

|

POWER(KW)

|

AIRFLOW(M3/H)

|

VOLTAGE(CUSTOM MADE)

|

DIMENSION(MM)

|

||||

|

DER-DE1200

|

1.1

|

1200

|

380V/50HZ31PH

|

900*800*1400

|

||||

|

DER-DE1500

|

1.5

|

1500

|

220V/50/60HZ/3PH

|

900*800*1400

|

||||

|

DER-DE2400

|

2.2

|

2400

|

115V/60HZ/1PH

|

|

||||

|

WITH AUNTOMATIC BACK BLOWING SYSTEM

|

|

|

|

|

||||

|

EXTRACTION ARM:ONE OR TWO EXTRACTION ARM

|

|

|

|

|

||||

TECHNICAL PARAMETER

DER-VE SERIES WELDING FUME EXTRACTOR

I Application Area

DER-VE type double arm type movable welding fume extractor is used for purifying smoke and dust generated in welding, cutting, polishing, grinding and other processes of rare metals, and precious materials such as the recovery of small metal particles, can purify a large amount of suspended harmful to the human body in the air. With high purification efficiency, low noise, flexible use, small footprint.

Suitable for electric arc welding, carbon dioxide welding, MAG welding, carbon arc gouging welding, gas cutting, special welding smoke in workplace.

|

MODEL

|

POWER(KW)

|

AIRFLOW(M3/H)

|

VOLTAGE(CUSTOM MADE)

|

DIMENSION(MM)

|

||||

|

DER-VE2400 (WITH DOUBLE CARTRIDGE FILTER )

|

2.2

|

2400

|

380V/50HZ31PH

|

900*800*1400

|

||||

|

DER-VE3600 (WITH DOUBLE CARTRIDGE FILTER )

|

3.0

|

3600

|

220V/60HZ/3PH

|

900*800*1400

|

||||

|

WITH AUNTOMATIC BACK BLOWING SYSTEM

|

|

|

|

|

||||

|

EXTRACTION ARM:ONE OR TWO EXTRACTION ARM

|

|

|

|

|

||||

Spare parts:

CARTRIDGE FILTER PVC HOSE EXTRACTION ARM

TECHNICAL PARAMETER

DER-MINI SERIES WELDING FUME EXTRACTOR

I Application Area

DER-MINI purification Mobile welding fume purifier is a light and high efficiency collector, which is designed according to the needs of various industrial dust collections.

It replies to the welding fumes, polishing, and other dust treatment in chemicals producing. Operators, who work for a long time in the environment of high concentration of dust, breathing in excess toxic substances, will cause headaches, nausea, asthma, chronic bronchitis and other symptoms, which seriously impact on health, and normal production.

|

MODEL

|

POWER(KW)

|

AIRFLOW(M3/H)

|

VOLTAGE(CUSTOM MADE)

|

DIMENSION(MM)

|

|

DER-MINI1200

|

0.75

|

1200

|

115V/60HZ/1PH

|

630*500*1000

|

|

DER-MINI1500

|

1.1

|

1200

|

220V/50HZ/1PH

|

630*500*1000

|

TECHNICAL PARAMETER

DER-CE-Z SERIES WELDING FUME EXTRACTOR

I Application Area

CE-Z series wall mounted type welding fume extractor professionally design for capturing the fume and dust, and provide service for the customer of purifying the fume and dust.

Product structure characteristics

■ Adopts the universal arm that can freely move 360°.

It can absorb the fume and dust from the source place that the fume smoke happens, greatly increases the collection rate of the fume and dust, and directly captures the dust at the source to ensure the welder's health.

■ The clean air is discharged after noise reduction from the air fan outlet.

■ Consumptive material performance stable in the purifier, easy to change.

■ Small size, small power, and easy operation.

■ The wall-mounted type purifier saves space and easy operation.

■ An external control box to control, and the control box can install the suitable position according to working condition.

|

MODEL

|

POWER(KW)

|

AIRFLOW(M3/H)

|

VOLTAGE(CUSTOM MADE)

|

DIMENSION(MM)

|

||||

|

DER-CE-Z1500

|

1.5

|

1500

|

380V/50HZ31PH

|

1150*700*600

|

||||

|

DER-CE-Z2400

|

2.2

|

2400

|

220V/50/60HZ/3PH

|

1150*700*600

|

||||

|

DER-CE-Z3600

|

3.0

|

3600

|

115V/60HZ/1PH

|

1150*700*600

|

||||

|

WITH AUNTOMATIC BACK BLOWING SYSTEM

|

|

|

|

|

||||

|

EXTRACTION ARM:ONE OR TWO EXTRACTION ARM

|

|

|

|

|

||||

Hot Searches