- Product Details

- {{item.text}}

Quick Details

-

Heating Power (kW):

-

20 kW

-

Place of Origin:

-

China

-

Brand Name:

-

FS

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

5200*2500*1200mm

-

Weight (T):

-

1 T

-

Max forming area:

-

540*480mm

-

PLC:

-

Mitsubishi

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Max.Forming Height(mm):

-

80 mm

-

Forming Width (mm):

-

480 mm

-

Forming Length (mm):

-

540 mm

-

Heating Power (kW):

-

20 kW

-

Place of Origin:

-

China

-

Brand Name:

-

FS

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

5200*2500*1200mm

-

Weight (T):

-

1 T

-

Max forming area:

-

540*480mm

-

PLC:

-

Mitsubishi

-

Marketing Type:

-

Ordinary Product

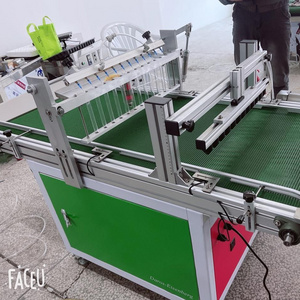

The machine is mainly used for making agriculture seedling tray, and also all kinds of machinery and food packaging products.

1. Feeding-Heating-Forming-cooling-demold-punching hole-cutting-counting.

2. This is a kind of new model, controlled by PLC touch screen, easy to operate.

3. The forming width can be adjusted, clients can adjust the width between 480mm — 250mm arbitrarily.

4. Use servo motor to feed sheet, feeding speed high, stable, and accuracy, save sheet

5. The heating radiation tiles design are special modified for seedling tray, each tile temperature can be adjusted, can save energy and increase product quality.

6. Upper and lower mold both driven by oil cylinder, can be adjusted synchronously and separately, forming stably and fast, increase production effecience

7. High wear-resisting aluminium alloy guide rail, can trough water cooling, increase product quality.

8. The machine sets a lighting equipment for clients, and we can add or change various functions according to the request of clients .

1. Warranty:1 Year

2. Maintenance: Lift-long maintenance

3. Installation: Engineers available to installation, commension and training overseas.

4. Spare parts: Enough for 2 years running.