- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XKJ

-

Dimension(L*W*H):

-

2770*1470*1640

-

Weight:

-

1230 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Max feeder size:

-

125-1500mm

-

Output size:

-

10-400mm

-

Color:

-

Customizable

-

Spare parts supply:

-

Lifelong Time

-

After sale Service:

-

Service Machinery Overseas

-

Test&Installation:

-

Professional Enginee Assigend

-

Technology:

-

18 year experienced technology support

-

Installation:

-

under technician guidance

-

Product name:

-

Jaw Stone Crusher Machine

Quick Details

-

Application:

-

mineral

-

Capacity(t/h):

-

1-5

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XKJ

-

Dimension(L*W*H):

-

2770*1470*1640

-

Weight:

-

1230 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Max feeder size:

-

125-1500mm

-

Output size:

-

10-400mm

-

Color:

-

Customizable

-

Spare parts supply:

-

Lifelong Time

-

After sale Service:

-

Service Machinery Overseas

-

Test&Installation:

-

Professional Enginee Assigend

-

Technology:

-

18 year experienced technology support

-

Installation:

-

under technician guidance

-

Product name:

-

Jaw Stone Crusher Machine

This small size PE series Diesel jaw crusher max. feeding size is 130-210mm, output size is 10-60mm, capacity is 1-20 tph. Mining crusher crushing materials including granite, basalt, limestone, river stone, sandstone, shale, iron ore, copper ore, building construction, construction wastes etc.

[ Capacity ]: 1–20 t/h

[ Applicable Material ]:

Jaw crusher is widely used in various industries, such as mining, road and railway construction, building construction,water conservation and chemical industry etc. It could crush kinds of minerals and rocks with compression strength less than 320MPa, such as quartz, granite, basalt, limestone, river stone, sandstone, shale, iron ore, copper ore, gold ore etc.

Jaw crusher is a kind of stone crushing machine which is widely used as primary or secondary crusher. Jaw crushers are designed modular to save time and installation costs.

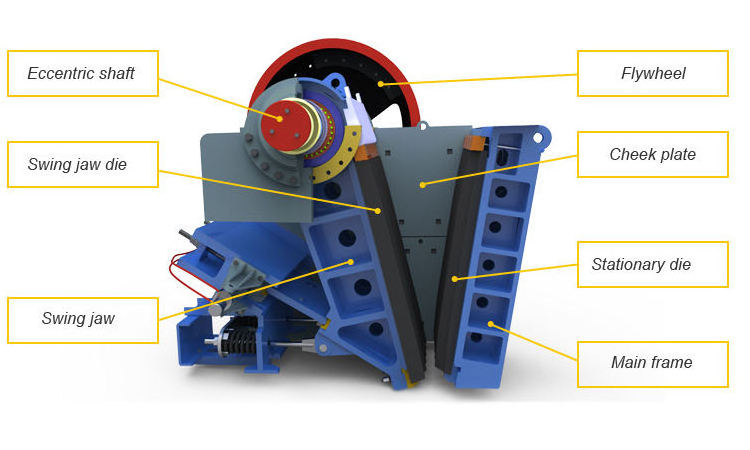

Structure Principle

Working principle The electromotor drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft. The raw material is squashed or splitt when movable jaw plate moves towards fixed jaw together with movable jaw. When movable jaw and movable jaw plate turn back by eccentric shaft and spring, the raw material, which is squashed or split before discharges from the bottom outlet under jaw plate. The bulk-production comes true while electromotor rotates continuously and the movable jaw crushes and discharges the raw material periodically.

Technical Parameter

| Model | Feeder Opening Size(mm) | Max. Feeding Size (mm) | Discharging Opening Size(mm) | Capacity (t/h) | Motor Power (kw) | Overall Dimension (mm) |

| PE150x250 | 150x250 | 130 | 10-45 | 1-4 | 5.5 | 896x745x935 |

| PE200x300 | 200x300 | 180 | 15-50 | 2-6 | 7.5 | 910x750x990 |

| PE200x350 | 200x350 | 180 | 18-70 | 3-10 | 7.5 | 1000x870x990 |

| PE250x400 | 250x400 | 210 | 25-60 | 5-20 | 15 | 1215x1240x1210 |

Product Details

Sometimes, some suitable equipment will be customized according to the actual situation of customers to save time and money and make it more convenient for customers to use, so as to get better promotion, such as crushing and conveying equipment and crushing and screening equipment

Maybe you are interested in