RO water purification machine / UF mineral water filtration machine.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.5%

-

Voltage:

-

380/220V 50/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LivingH2O

-

Dimension(L*W*H):

-

280*210*240CM

-

Weight:

-

3500 KG

-

Product name:

-

Beer can filler and seamer machine

-

Other name:

-

aluminium can carbonated drinks packaging closing pressing machine

-

Packing type:

-

PET/Aluminum can

-

Filling volume:

-

50-1000ml

-

Production Capacity:

-

1000-36000CPH

-

Processing:

-

soft drinks pre-processing, filling, capping, packing Line

-

Filling liquid:

-

carbonated soft drinks

-

Label type:

-

Sticker/sleeve label

-

Bottle packing type:

-

film wrap packing/carton

-

Material:

-

Stainless Steel SUS304

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

99.5%

-

Voltage:

-

380/220V 50/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LivingH2O

-

Dimension(L*W*H):

-

280*210*240CM

-

Weight:

-

3500 KG

-

Product name:

-

Beer can filler and seamer machine

-

Other name:

-

aluminium can carbonated drinks packaging closing pressing machine

-

Packing type:

-

PET/Aluminum can

-

Filling volume:

-

50-1000ml

-

Production Capacity:

-

1000-36000CPH

-

Processing:

-

soft drinks pre-processing, filling, capping, packing Line

-

Filling liquid:

-

carbonated soft drinks

-

Label type:

-

Sticker/sleeve label

-

Bottle packing type:

-

film wrap packing/carton

-

Material:

-

Stainless Steel SUS304

Product Description

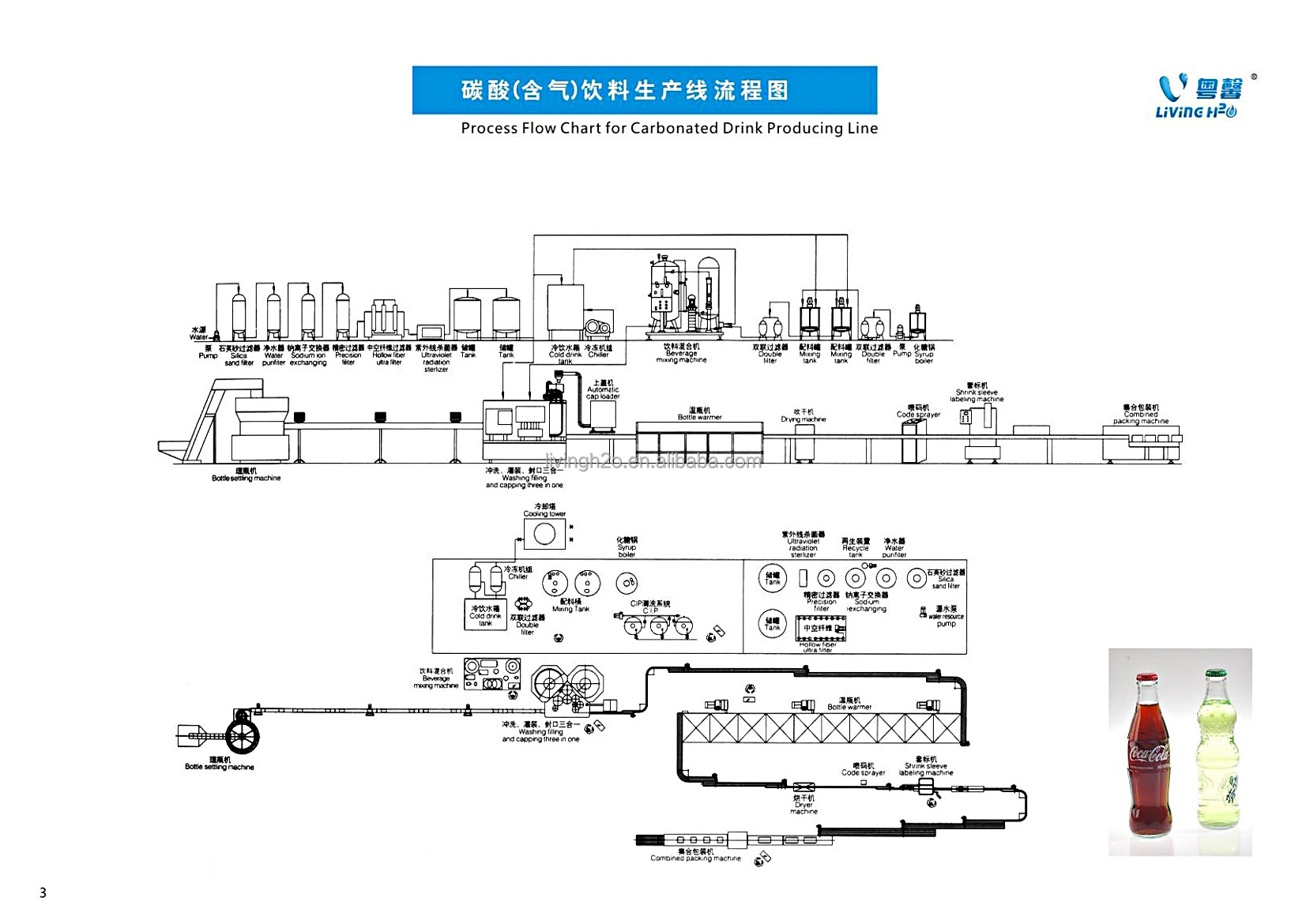

Aluminum c an c arbonated soft drinks production line plant machinery:

We provide the turn-key solution, including: water treatment system, drinks mixing tanks, cold water tank & cooling device, carbonated drink mixing machine, carbon dioxide filter, injection system, aluminum can filling sealing machine, t unnel type aluminum can warming machine, packaging machine, conveyor system, electrical system, cable wire, etc, and related raw materials: aluminum can s, cover, plastic particles, labels, shrink film, clean room building material etc. The corresponding pre-sale whole plant planning drawings and after-sales installation and debugging maintenance, we all supply a A to Z complete service.

One partner for all your needs.

A complete CSD line solution from Livingh2o takes into account every step of your aluminum can carbonated soft drink process, from mini mising resource waste to determining your aluminum can's ideal look and weight. With everything centred around one supplier, you get wide-ranging expertise, line equipment and ongoing services. This ensures high quality and efficiency from packaging to equipment, fast ramp-up and beyond.

Optional production capacity:

1000-2000 cans per hour;

2000-3000 cans per hour;

3000-4000 cans per hour;

5000-6000 cans per hour;

7000-9000 cans per hour;

10000-12000 cans per hour;

15000-18000 cans per hour;

18000-24000 cans per hour;

25000-36000 cans per hour;

More...

1000-2000 cans per hour;

2000-3000 cans per hour;

3000-4000 cans per hour;

5000-6000 cans per hour;

7000-9000 cans per hour;

10000-12000 cans per hour;

15000-18000 cans per hour;

18000-24000 cans per hour;

25000-36000 cans per hour;

More...

Aluminum can

soft drinks

production line production processes:

Water treatment machine--

Mixing tanks---

Cold water tank & cooling device

--

-

Carbonated drink mixing machine

---

Carbon dioxide filter

-- 3 in 1 Washing filling sealing machine--Light checker--Tunnel type can warming machine----can blow dryer---Labeling machine ---Dater coding machine---Packing machine ---Stock

Details Images:

1. (Water Filtration)

2. (Carbonated

soft

drinks pre-process )

Syrup melting tank, mixing tanks, cold water tank & cooling device, carbonated drink mixing machine, carbon dioxide filter, UHT sterilizer, homogenizer machine, buffer tank, CIP cleaning system etc.

3. (Filling carbonated

soft

drinks into

aluminum can

)

washing filling and sealing machine.

4. (Tunnel type bottle

warming

machine)

Bottle warming machine adopts

the cycle increasing water temperature to carry on the stage type heat bottle.

5. (Labeling bottle carbonated

soft

drinks)

Shrink sleeve labeling machine or Sticker labeling machine..

6. (Printing the date on the bottle

carbonated

soft

drinks

)

Date coding printing machine.

7. (Package the bottle

carbonated

soft

drinks

)

Full automatic shrink wrapping packing machine or Semi automatic shrink wrapping packing machine /Carton box packing machine

Enjoy natural drink, enjoy healthy life.

Carbonated soft drinks to water as a basic raw material, produced by different formulations and manufacturing process for people drink directly. In addition to providing water, because it contains varying amounts of sugar, acid, milk, sodium, fat, energy and various amino acids, vitamins, inorganic salts and other nutrients in the different types of beverages, so there are certain nutrients.

All kinds of carbonated soft drinks in supermarkets and stores, can be found in a comprehensive solution in Livingh2o. Livingh2o provides comprehensive packaging solutions: relative to a single equipment, we pursue the turn key production line of liquid products “aggregate” efficiency and capacity; relative to a single production line, we focus on covering most of the beverage plant design and integration.

Carbonated soft drinks to water as a basic raw material, produced by different formulations and manufacturing process for people drink directly. In addition to providing water, because it contains varying amounts of sugar, acid, milk, sodium, fat, energy and various amino acids, vitamins, inorganic salts and other nutrients in the different types of beverages, so there are certain nutrients.

All kinds of carbonated soft drinks in supermarkets and stores, can be found in a comprehensive solution in Livingh2o. Livingh2o provides comprehensive packaging solutions: relative to a single equipment, we pursue the turn key production line of liquid products “aggregate” efficiency and capacity; relative to a single production line, we focus on covering most of the beverage plant design and integration.

Product Paramenters

|

Model

|

LIVING 8-8-3C

|

|

Production Capacity (CPH) (250ml)

|

1500-2000

|

|

Filling Pressure (Mpa)

|

≤0.4

|

|

Applicable Can Type

|

(Aluminum Can Diameter)Φ50-Φ100mm (Height)100-320mm (Volume)200-1000ml

|

|

Applicable Cover

|

Aluminum cover

|

|

Gas Source Pressure (Mpa)

|

0.6

|

|

Gas Consumption (m3/min)

|

0.2

|

|

Total Power (kw)

|

4.0

|

|

Model

|

LIVING 16-12-6C

|

|

Production Capacity (CPH) (250ml)

|

3000-4000

|

|

Filling Pressure (Mpa)

|

≤0.4

|

|

Applicable Can Type

|

(Aluminum Can Diameter)Φ50-Φ100mm (Height)100-320mm (Volume)200-1000ml

|

|

Applicable Cover

|

Aluminum cover

|

|

Gas Source Pressure (Mpa)

|

0.6

|

|

Gas Consumption (m3/min)

|

0.25

|

|

Total Power (kw)

|

4.8

|

|

Model

|

LIVING 18-18-6C

|

|

Production Capacity (CPH) (250ml)

|

4000-6000

|

|

Filling Pressure (Mpa)

|

≤0.4

|

|

Applicable Can Type

|

(Aluminum Can Diameter)Φ50-Φ100mm (Height)100-320mm (Volume)200-1000ml

|

|

Applicable Cover

|

Aluminum cover

|

|

Gas Source Pressure (Mpa)

|

0.6

|

|

Gas Consumption (m3/min)

|

0.3

|

|

Total Power (kw)

|

5.03

|

Recommend Products

Hot Searches