- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

MB-01

-

Material:

-

Carbon steel, stainless steel, aluminum, brass

-

Finish:

-

Powder Coating, Anodizing, Brushing, Polishing, Electric-plating

-

Application:

-

Office Building, Marble fixing

Quick Details

-

Structure:

-

Single-side Bracket

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YC

-

Model Number:

-

MB-01

-

Material:

-

Carbon steel, stainless steel, aluminum, brass

-

Finish:

-

Powder Coating, Anodizing, Brushing, Polishing, Electric-plating

-

Application:

-

Office Building, Marble fixing

Products Description

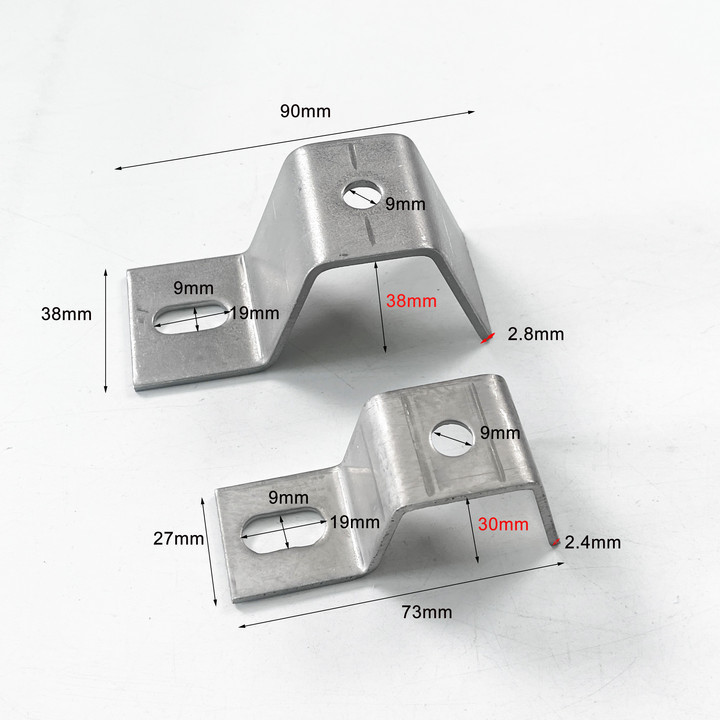

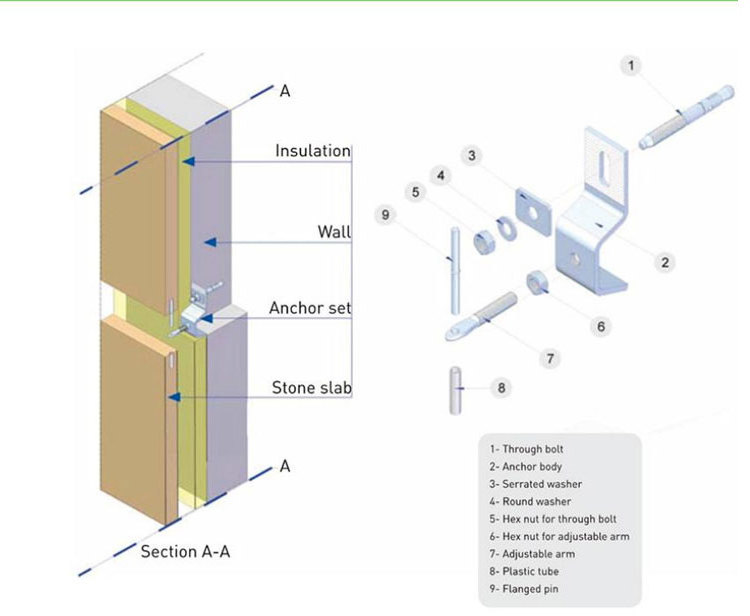

Fixing Bracket For Cladding System

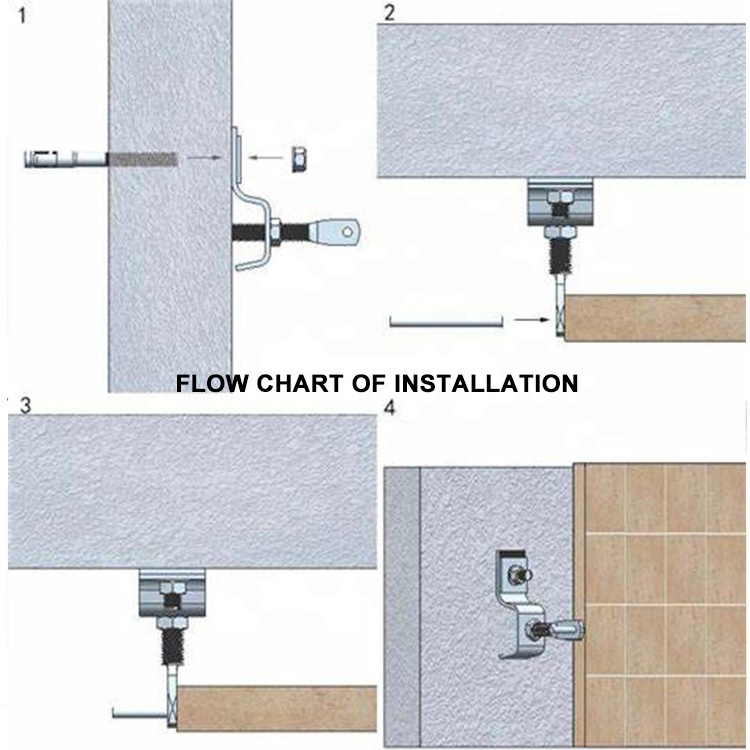

1.

Suitable for concrete walls

. Anchors are fixed directly on to concrete walls with expansion bolts.

2. In horizontal joint installation slabs are pinned on the bottom and upper sides. Anchors act as load bearing carrying half.

3. The weight of the slabs above. Anchors also act as restraint holding the slabs below and restraining against wind suction and pressure.

4. In vertical joints installation slabs are pinned at the left and right sides. Anchors on the bottom are load-bearing anchors carrying the whole weight of the slab. Half the weight of the slab on the left and half the weight of the slab on the right. Anchors on the top are restraint anchors holding the slabs and restraining against wind suction and pressure .

5. Three - dimensional adjustability allows quick and easy installation.

2. In horizontal joint installation slabs are pinned on the bottom and upper sides. Anchors act as load bearing carrying half.

3. The weight of the slabs above. Anchors also act as restraint holding the slabs below and restraining against wind suction and pressure.

4. In vertical joints installation slabs are pinned at the left and right sides. Anchors on the bottom are load-bearing anchors carrying the whole weight of the slab. Half the weight of the slab on the left and half the weight of the slab on the right. Anchors on the top are restraint anchors holding the slabs and restraining against wind suction and pressure .

5. Three - dimensional adjustability allows quick and easy installation.

Advantages

1. The panels are secured to the anchoring base material with absolute safety.

2. Manufactured from stainless steel.

3. The support and restraint brackets are adjustable.

4. The brackets are fixed into the anchoring base by means of anchors. Due to the small drill hole dimensions of the anchors, the facade can be installed very quickly. The small size of drill hole into the anchoring base material means that heavy drilling equipment is not required.

1. The panels are secured to the anchoring base material with absolute safety.

2. Manufactured from stainless steel.

3. The support and restraint brackets are adjustable.

4. The brackets are fixed into the anchoring base by means of anchors. Due to the small drill hole dimensions of the anchors, the facade can be installed very quickly. The small size of drill hole into the anchoring base material means that heavy drilling equipment is not required.

|

Projec-tion

|

Dead Load

|

Forming Size

|

Wind-Pressure

|

ExpansionBolt Size

|

Pin Size

|

Adj.Arm Metric Size

|

Adj.Arm Flat Thickness

|

Adj.Arm Length

|

|

K(mm)

|

Fdw(N)

|

F(mm)

|

Fwp(N)

|

E.b.(mm)

|

Ø(mm)

|

M(mm)

|

T(mm)

|

EAL(mm)

|

|

45

|

200 |

10

|

312 |

M8×80 |

5 |

M10 |

3.5 |

60

|

|

55

|

|

20

|

|

|

|

|

|

60

|

|

75

|

|

40

|

|

|

|

|

|

60

|

|

95

|

|

60

|

|

|

|

|

|

60

|

|

55

|

300 |

20

|

468 |

M8×80 |

5 |

M10 |

3.5 |

60

|

|

75

|

|

40

|

|

|

|

|

|

60

|

|

95

|

|

60

|

|

|

|

|

|

60

|

|

115

|

|

80

|

|

|

|

|

|

60

|

|

55

|

400 |

10

|

624 |

M8×80 |

5 |

M12 |

4.5 |

70

|

|

75

|

|

20

|

|

|

|

|

|

90

|

|

95

|

|

40

|

|

|

|

|

|

90

|

|

115

|

|

60

|

|

|

|

|

|

90

|

|

75

|

500 |

20

|

780 |

M8×80 |

5 |

M12 |

4.5 |

90

|

|

95

|

|

40

|

|

|

|

|

|

90

|

|

115

|

|

60

|

|

|

|

|

|

90

|

|

135

|

|

80

|

|

|

|

|

|

90

|

|

75

|

600 |

20

|

936 |

M10×90 |

6 |

M14 |

5.5 |

90

|

|

95

|

|

40

|

|

|

|

|

|

90

|

|

115

|

|

60

|

|

|

|

|

|

90

|

|

135

|

|

80

|

|

|

|

|

|

90

|

|

75

|

800 |

20

|

1235 |

M10×90 |

6 |

M14 |

5.5 |

90

|

|

95

|

|

40

|

|

|

|

|

|

90

|

|

115

|

|

60

|

|

|

|

|

|

90

|

|

135

|

|

80

|

|

|

|

|

|

90

|

Product Application

Product Packaging

Hot Searches