- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SWANTECH

-

Voltage:

-

220VAC/380VAC

-

Dimension(L*W*H):

-

1000*900*900mm

-

Weight (KG):

-

200 kg

-

Product Name:

-

Brick Macking Machine

-

Raw material:

-

Sand

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Block Type:

-

Hollow Concrete Brick Machine

-

Color:

-

Customer's Demand

-

Advantage:

-

High Efficiency

-

Application:

-

Buliding Construction

-

Molding cycle:

-

45s

-

Brick type:

-

Hollow Brick Concrete Brick Hole Brick

-

Vibration frequency:

-

2800-4500r/min

Quick Details

-

Type:

-

Hollow Block Making Machine

-

Brick Raw Material:

-

Sand/Cement/Clay/Fly Ash

-

Production Capacity (Pieces/8 hours):

-

1000 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SWANTECH

-

Voltage:

-

220VAC/380VAC

-

Dimension(L*W*H):

-

1000*900*900mm

-

Weight (KG):

-

200 kg

-

Product Name:

-

Brick Macking Machine

-

Raw material:

-

Sand

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Block Type:

-

Hollow Concrete Brick Machine

-

Color:

-

Customer's Demand

-

Advantage:

-

High Efficiency

-

Application:

-

Buliding Construction

-

Molding cycle:

-

45s

-

Brick type:

-

Hollow Brick Concrete Brick Hole Brick

-

Vibration frequency:

-

2800-4500r/min

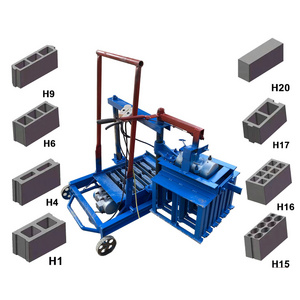

Cheap Price manufacturer Manual Hollow Maker soil clay interlocking Concrete Cement Brick Block Making Machine Price For Sale

The

manual block-making machine

is one of our sell best block-making machines, suitable for making all types of

hollow blocks, solid blocks, pavers, curbstones, and so on.

The machine is designed with reasonable structure and advanced technology. Four vertical axis guidance, upper die push and pull, automatic scraping, reducer lifting mode. Thereby increasing block forming speed, increasing block density and reducing raw material consumption. It Only 1 people are needed for production and transportation, and the investment is low, so this manual hollow block machine is very suitable for factories or family businesses.

Specification

|

Model

|

2-45A

|

|

Power

|

1.5KW

|

|

Weight

|

200KG

|

|

Voltage

|

220V/380V

|

|

Molding cycle

|

45S

|

|

Production size(mm)

|

400*200*200/390*190*190/390*150*190/390*120*190/240*120*50 etc.

|

|

Raw material

|

Sand, Gravel, Cement, Fly ash, Slag, Steel slag, Perlite, etc.

|

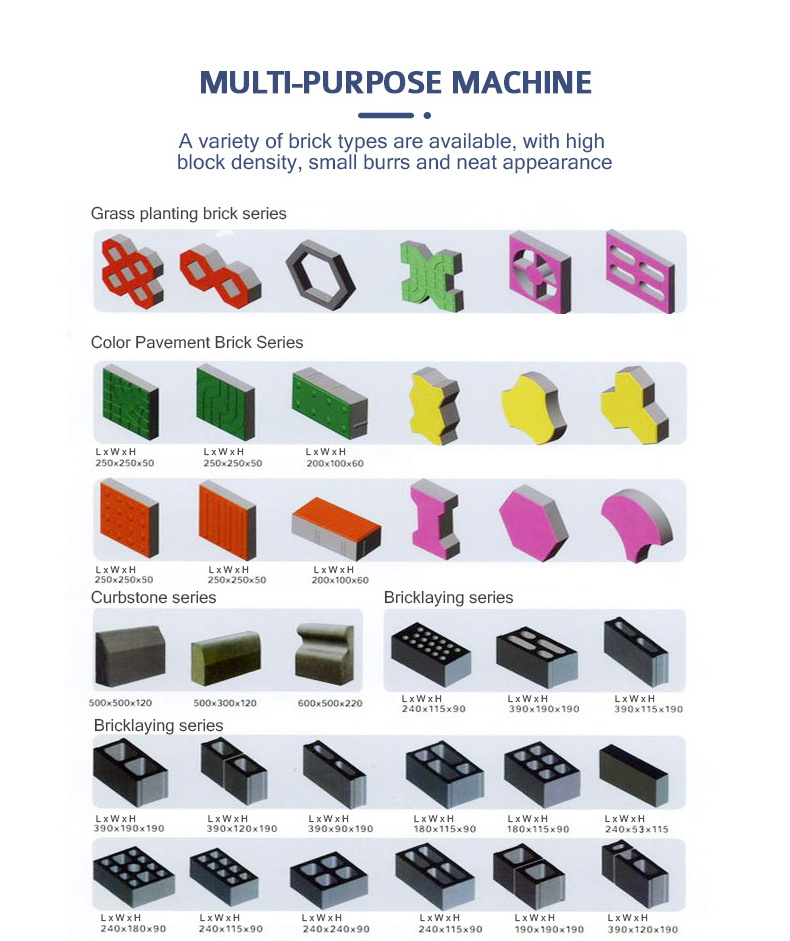

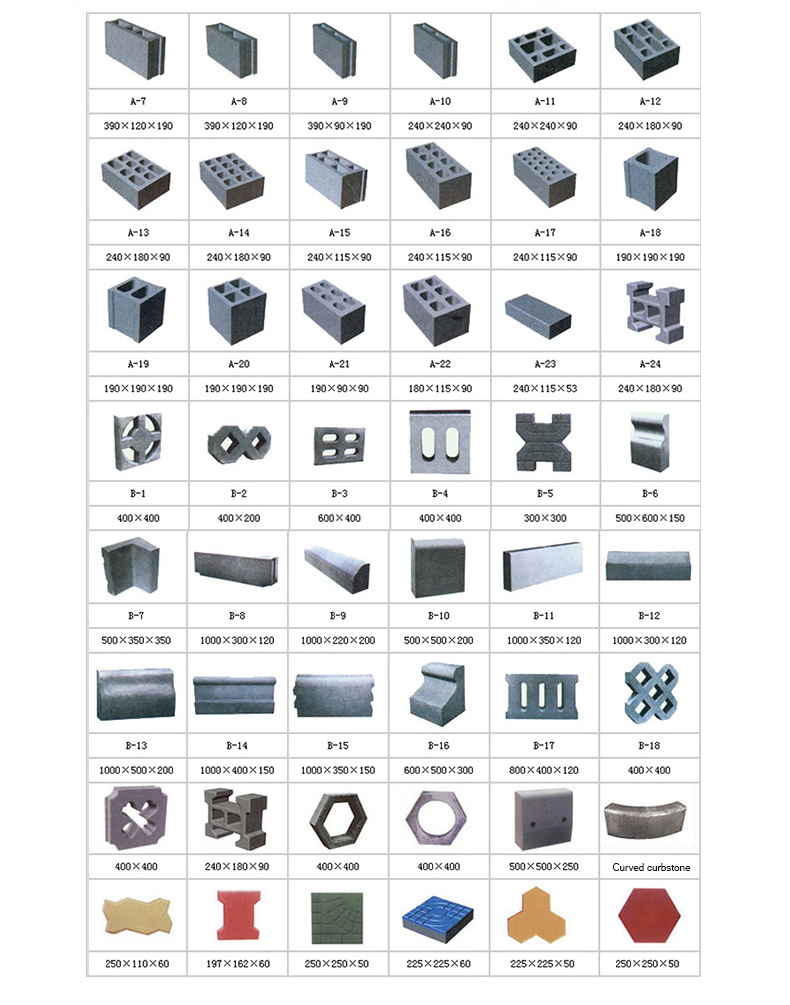

Product Description

The brick moulds are made of

16# manganese steel.

Besides the good raw material, precise line cutting technology and 900℃,carburizing heat treatment technology are all adopted in the process of the brick mould production. So the brick moulds have better performance and longer service time.

The mould can be customized according to your need.

Details Images

1.

Multi function:

2-45 concrete block machine can produce various hollow blocks, solid blocks, pavers and curbs by changing molds.

2.

Strong and durable, high density brick:

Adopt new technology mold vibration mode to make brick., which makes the working state of brick machine more stable and efficient, and produces bricks with better quality, higher density and higher strength.

Vibration System:

1.Adopt vibration moulding technology and equipped with three vibrators to assure better quality, larger density and higherstrength of the blocks.

2.Low power can achieve super super moulding effect.

We have a

motor type and diesel engine type

hollow brick-making machine. You can choose according to your requirement.

1. Motor type hollow brick-making machine( Inclined push type and Straight push type)

2. Diesel engine type hollow brick making machine

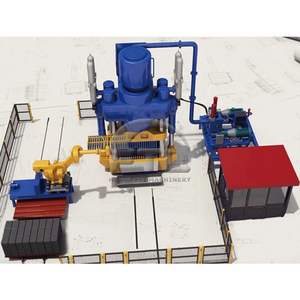

Packing & Delivery

Packing is nude package, plastic and wooden case according to customer need:

1. The whole brick machine production line equipment is mainly the full container sea shipping,

2. Before shipment, the top paint of the brick machine equipment will be tested and cleaned up, and then another paint protection will be done.

3. Before shipment, it can be wrapped with plastic film according to customer needs, and the whole brick machine is wrapped to prevent water or moisture.

4. The brick machine is then loaded into the container by a crane or forklift.

5. When loading, the reinforcing ring and special equipment in the container are used to tighten the machine to prevent damage to the brick machine caused by transportation bumps.

Hot Searches