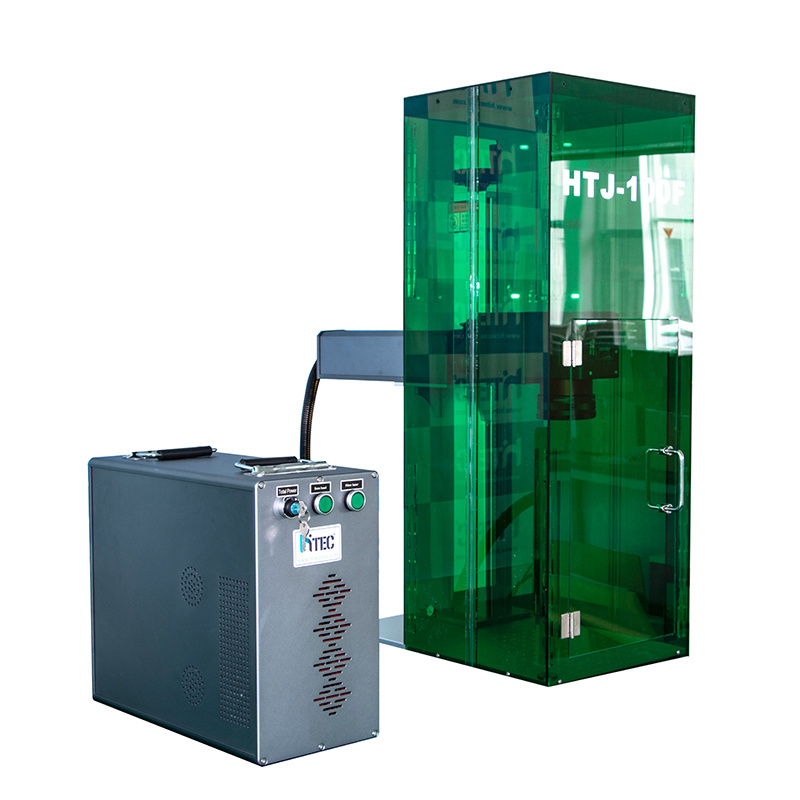

- Product Details

- {{item.text}}

Quick Details

-

Cooling Mode:

-

Air cooling

-

Control Software:

-

3D lenmark

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HITEC

-

Marking Head Brand:

-

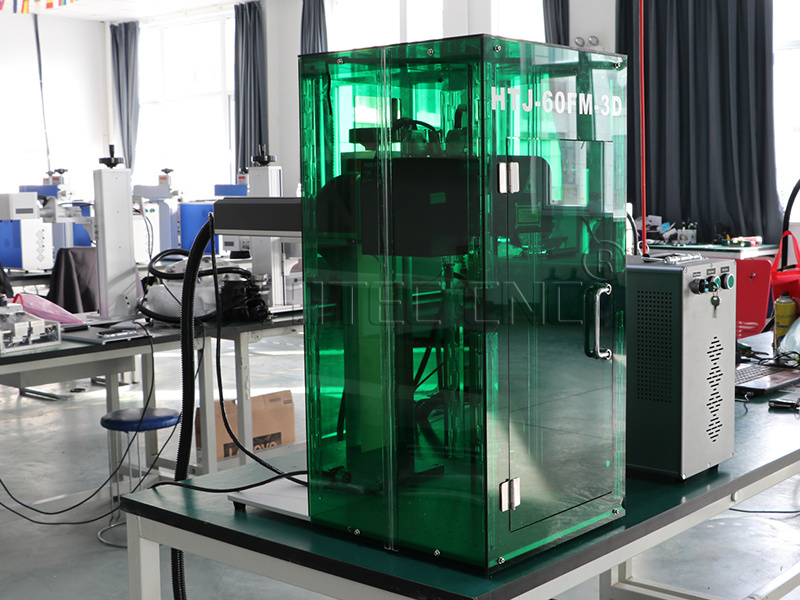

HTJ-100FM-3D

-

Weight (KG):

-

70 KG

-

Core Components:

-

laser head

-

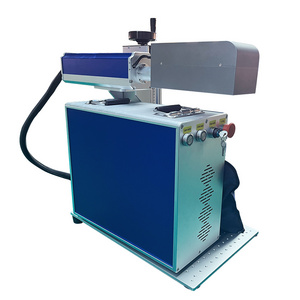

JPT Color Fiber Laser Marking Machine:

-

JPT Color Fiber Laser Marking Machine

-

laser head:

-

3d Feeltek dynamic laser head

-

Laser source:

-

JPT Mopa 60w Laser Source

-

Marking Speed:

-

0-10000mm/s

-

Working area:

-

200x200mm

-

Control card:

-

Feelteck control card and system

-

Marking material:

-

SS CS Aluminum Metal Plastic ect

-

Wavelength:

-

1064 10 Nm

-

Laptop:

-

Included

-

Operating voltage:

-

110v/220v

Quick Details

-

Working Accuracy:

-

0.001

-

Graphic Format Supported:

-

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP, STL

-

Laser Type:

-

Fiber Laser

-

Cooling Mode:

-

Air cooling

-

Control Software:

-

3D lenmark

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HITEC

-

Marking Head Brand:

-

HTJ-100FM-3D

-

Weight (KG):

-

70 KG

-

Core Components:

-

laser head

-

JPT Color Fiber Laser Marking Machine:

-

JPT Color Fiber Laser Marking Machine

-

laser head:

-

3d Feeltek dynamic laser head

-

Laser source:

-

JPT Mopa 60w Laser Source

-

Marking Speed:

-

0-10000mm/s

-

Working area:

-

200x200mm

-

Control card:

-

Feelteck control card and system

-

Marking material:

-

SS CS Aluminum Metal Plastic ect

-

Wavelength:

-

1064 10 Nm

-

Laptop:

-

Included

-

Operating voltage:

-

110v/220v

Fiber laser marking machine applied Industries

Curved surface marking: In the traditional 2D marking machine, the workpiece must be placed on the same plane, and the processing surface must also be on the same plane, in order to achieve the marking once formed, and the surface marking cannot be completed. The 3D laser marking machine can quickly change the laser focal length and laser beam orientation, and can achieve curved surface marking that cannot be done in 2D.

Deep carving: The traditional 2D marking has inherent defects when deep carving the object surface. As the laser focus moves upward during the engraving process, the laser energy acting on the actual surface of the object will drop sharply, which seriously affects the effect and efficiency of deep engraving. Therefore, it is necessary to move the lifting table at a specific height every specific time during the engraving process to ensure the laser surface gathering effect.

The 3D laser marking machine has greatly reduced the surface flatness requirements of the processed objects. In the process of deep carving, it not only ensures the effect, but also improves the efficiency, and the processable effect is more abundant.

The 3D laser marking machine adopts the front focusing optical form and uses larger X and Y axis deflection lenses, so it can allow a larger transmitted laser spot, better focusing accuracy and better energy effect; 3D laser marking machine compared with the 2d laser marking machine, the marking scale can be larger when gathering precision operations. The 3D laser marking machine can achieve one-time marking on the cylinder within a specific arc, which greatly improves the processing power.

In the industrial production process, the appearance of many parts is irregular, and the height of some parts is quite different. 2D marking processing is difficult to meet the needs. The advantages of 3D laser marking will gradually become more prominent.

Marking Materials

Fiber lasers can be used for a wide variety of applications, from industrial traceability to branding, on materials such as steel, copper, aluminum, plastic, ceramic, and brass..

|

Fiber laser marking machine parameter

|

|

|

|

|||

|

Item

|

Core parameters

|

|

Configurable parameters

|

|||

|

Power

|

Engraving area

|

Applicable material

|

laser source power

|

|||

|

1

|

200x200mm

|

Metal/ plastic/ Crystal

|

50w 60w 80w 100w

|

|||

|

2

|

600x600mm

|

|

|

|||

|

Related keywords

|

fiber laser marking machine, laser marking machine, metal laser marking machine, cnc fiber laser marking machine, laser marker

|

|

|

|||

|

Laser Wavelength

|

1064nm

|

1064nm

|

|

|||

|

Minimum Line Width

|

0.015mm

|

0.015mm

|

|

|||

|

Minimum Character

|

0.2mm

|

0.2mm

|

|

|||

|

Repeated Precision

|

±0.003mm

|

0.2mm

|

|

|||

|

Software

|

3D lenmark

|

3D lenmark

|

|

|||

|

Life-span of Fiber Laser Module

|

Beam Quality

|

3D lenmark

|

|

|||

|

Beam Quality

|

M2 <1.6

|

M2 <1.6

|

|

|||

|

Focus Spot Diameter

|

<0.01mm

|

<0.01mm

|

|

|||

|

System Operation Environment

|

Windows XP / Windows 7 / Windows 8

|

XP/ Win7/Win8 etc

|

|

|||

|

Cooling Mode

|

Air cooling--Built-in

|

Air cooling--Built-in

|

|

|||

|

Temperature of Operation Environment

|

15℃~35℃

|

15℃~35℃

|

|

|||

|

Power Stability (8h)

|

<±1.5%rms<±1.5%rms

|

<±1.5%rms

|

|

|||

|

Voltage

|

|

220V / 50HZ / 1-PH or 110V / 60HZ / 1-PH

|

|

|||

|

Power Requirement

|

|

<500W

|

|

|||

|

Computer Requested

|

There will be one PC with the machine

|

There will be one PC with the machine

|

|

|||

|

Dimension (L*W*H)

|

|

900mm*880mm*1560mm

|

|

|||

|

Package Size

|

|

980mm*950mm*1650mm

|

|

|||

|

Gross Weight

|

50KG

|

70KG

|

|

|||

|

Net Weight

|

|

60KG

|

|

|||

|

Optional (Not free of charge)

|

|

Rotary Device, Moving Table, other customized Automatic Matching System

|

|

|||

3D Fiber laser marking machine advantage than 2D

1. Variable focal length to realize three-dimensional marking

Because 3D marking can quickly change the laser focal length and laser beam position, it becomes possible to mark curved surfaces that cannot be achieved in 2D.

2.

More suitable for deep carving

Traditional 2D marking has inherent defects in deep engraving of the object surface. As the laser focus moves up during the engraving process, the laser energy acting on the actual surface of the object will drop sharply, which seriously affects the effect and efficiency of deep engraving.

3D marking for deep engraving processing does not have the above problems.

3.

Larger range and finer light effects

3D marking can be divided into front focus and back focus. When the front focus mode is used, the main purpose is to achieve a larger marking range.

4.

In the same plane, black and white marking can be realized, and even multi-color marking can be achieved, with richer effects

Surface blackening, such as anodized aluminum, usually uses higher-frequency pulses at appropriate energy to mark with a certain defocus. The defocus distance significantly affects the energy distribution and color effect of the laser on the surface of the material.