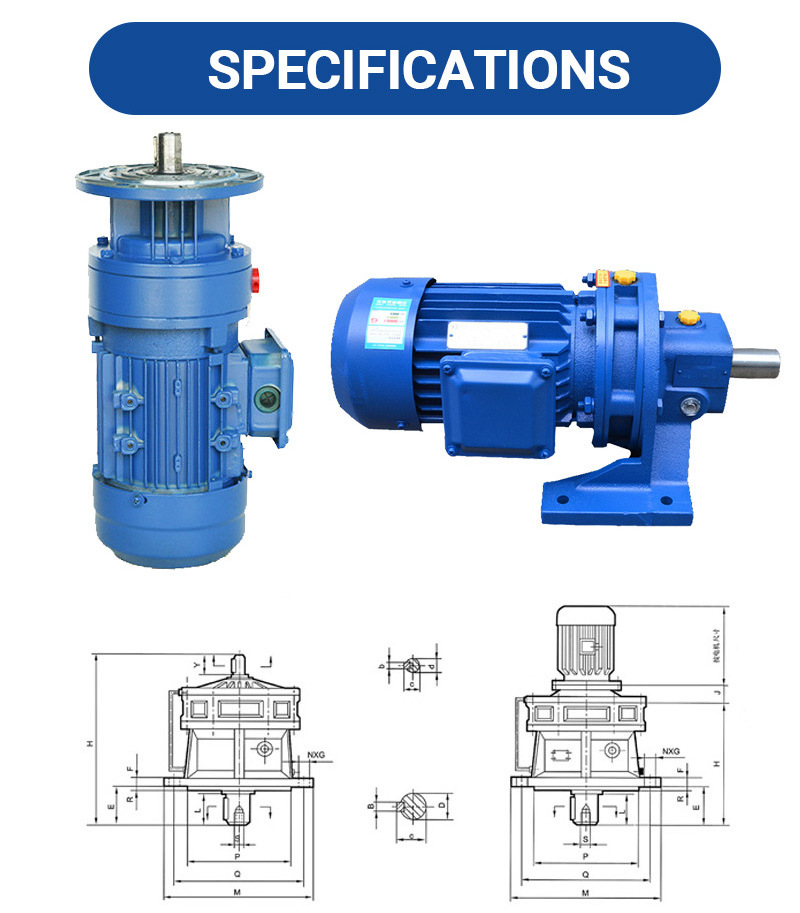

The cycloidal pinwheel reducer adopts the principle of cycloid pin-tooth meshing and planetary transmission, so it is usually called a planetary cycloid reducer. The planetary cycloidal pinwheel reducer can be widely used in petroleum, environmental protection, chemical industry, cement, transportation, Textile, pharmaceutical, food, printing, hoisting, mining, metallurgy, construction, power generation and other industries, as a driving or deceleration device, the machine is divided into horizontal, vertical, biaxial and direct-connected assembly methods

- Product Details

- {{item.text}}

Quick Details

-

Output Speed:

-

14-280rpm

-

Warranty:

-

1 year

-

Weight (KG):

-

55 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

speed

-

Material:

-

Cast Iron

-

Color:

-

Customer Requirement

-

Certificate:

-

ISO9001

-

Mounting:

-

Foot mounted, flange mounted

-

Product name:

-

Cycloid Speed Reducer

Quick Details

-

Gearing Arrangement:

-

Planetary

-

Output Torque:

-

50~2300Nm

-

Input Speed:

-

300-1800Rpm

-

Output Speed:

-

14-280rpm

-

Warranty:

-

1 year

-

Weight (KG):

-

55 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

speed

-

Material:

-

Cast Iron

-

Color:

-

Customer Requirement

-

Certificate:

-

ISO9001

-

Mounting:

-

Foot mounted, flange mounted

-

Product name:

-

Cycloid Speed Reducer

Product Details

Cycloid Reducer

The cycloidal pinwheel reducer is a novel transmission device that applies the principle of planetary transmission and adopts the meshing of cycloid pin teeth. The entire transmission device of the cycloid reducer can be divided into three parts: the input part, the deceleration part, and the output part.

|

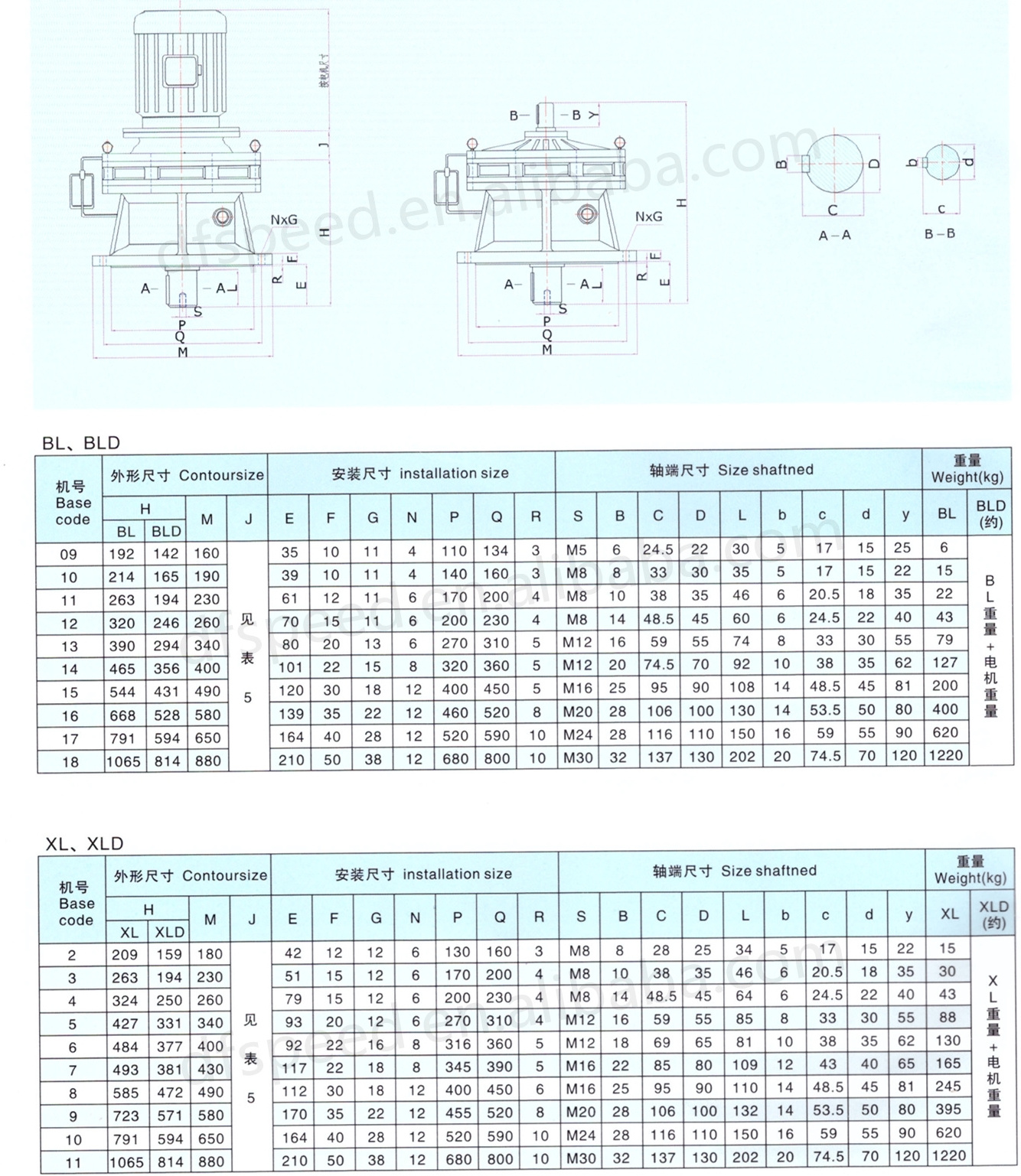

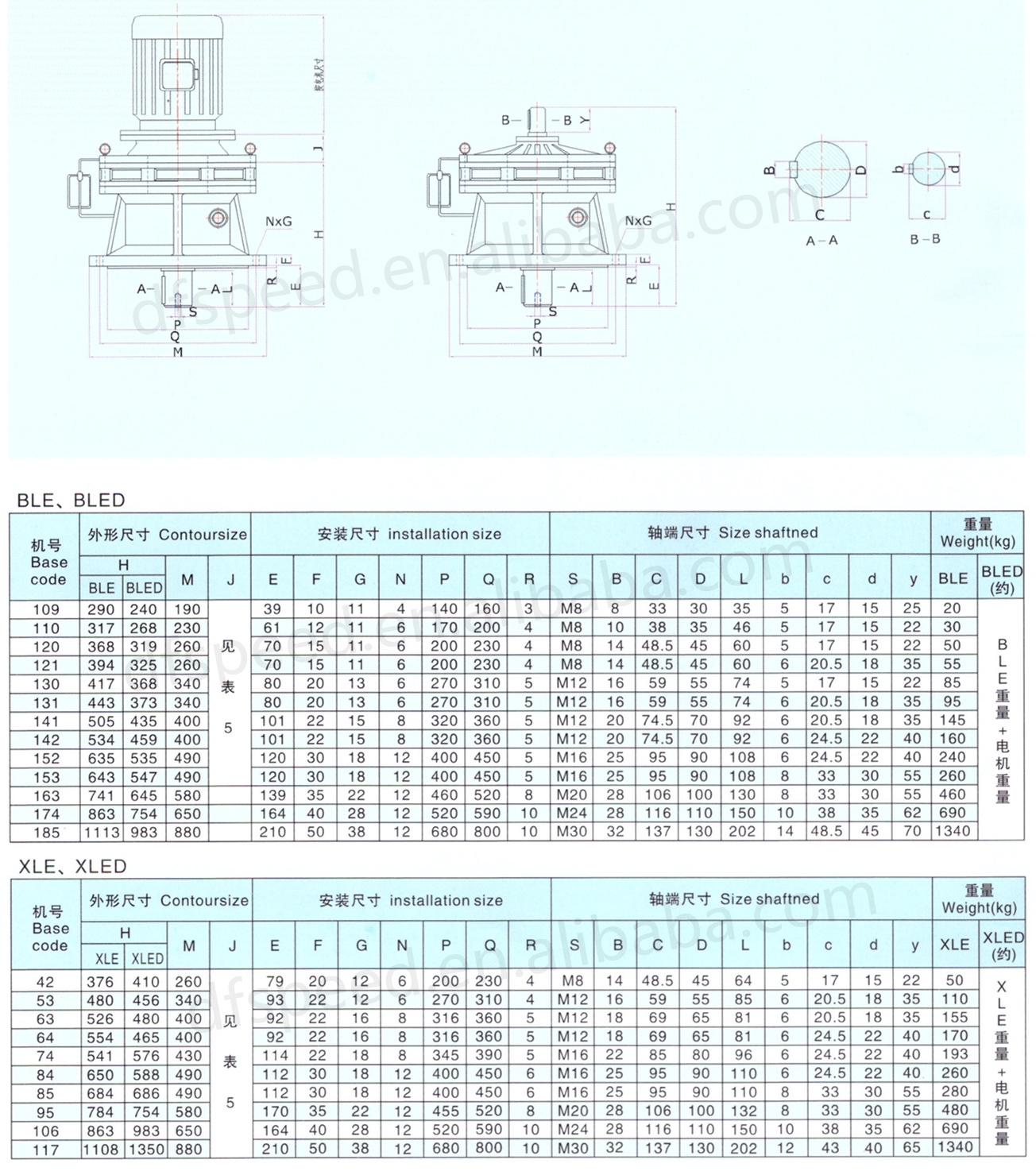

Model:

|

BWD, BXD,XLD,BLD

|

|

Installation:

|

direct connection installation, flange installation

|

|

Motor:

|

factory equipped motor, Siemens, ABB, etc.

|

|

Ratio

|

Stage Ratio:9, 11, 17, 23, 29, 35, 43, 59, 71, 87

Stage Ratio: 121, 187, 289, 385, 473, 595, 731, 989, 1225, 1849

|

Specification

Features

1. It can achieve a high reduction ratio of 1:87 and a high-efficiency single-stage transmission of more than 90%. If multi-stage transmission is used, the reduction ratio is larger.

2. The reduction ratio of the first-stage transmission is 9~87, the reduction ratio of the double-stage transmission is 121~5133, the multi-stage combination can reach tens of thousands, and the pin-tooth meshing system has rolling friction, and the meshing surface has no relative sliding, so the first-stage deceleration The efficiency is 94%.

3. Compact structure and small volume Due to the planetary transmission principle, the input shaft and the output shaft are on the same axis line, so that the model can obtain the smallest size possible.

Conditions of Use

1. The cycloidal pinwheel reducer is allowed to be used in the occasion of continuous working system, and it is allowed to run in both forward and reverse directions at the same time. Some models of cycloid reducer only allow one-way rotation.

2. The rated speed of the input shaft is 1500 rpm. When the input power is greater than 18.5 kW, it is recommended to use a 960 rpm 6-pole motor.

3. The working position of the horizontally installed cycloid reducer is the horizontal position. The maximum horizontal inclination angle during installation is generally less than 15°. When it exceeds 15°, other measures should be taken to ensure sufficient lubrication and prevent oil leakage.

4. The output shaft of the cycloid reducer cannot be subjected to large axial force and radial force, and other measures must be taken when there is a large axial force and radial force.

Hot Searches