- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Wodetec

-

Type:

-

grouting pump station

-

Dimensions:

-

3300*1650*1500mm

-

Mixer capacity:

-

250L

-

Mixer output:

-

4m3/h

-

Agitator capacity:

-

350L

-

Agitator rated Rev.:

-

36rpm

-

Water tank:

-

60L

-

Pump max. output:

-

100L/min

-

Pump max. pressure:

-

10MPa

-

After Warranty Service:

-

Online support

Quick Details

-

Weight (KG):

-

1440

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wodetec

-

Type:

-

grouting pump station

-

Dimensions:

-

3300*1650*1500mm

-

Mixer capacity:

-

250L

-

Mixer output:

-

4m3/h

-

Agitator capacity:

-

350L

-

Agitator rated Rev.:

-

36rpm

-

Water tank:

-

60L

-

Pump max. output:

-

100L/min

-

Pump max. pressure:

-

10MPa

-

After Warranty Service:

-

Online support

Description

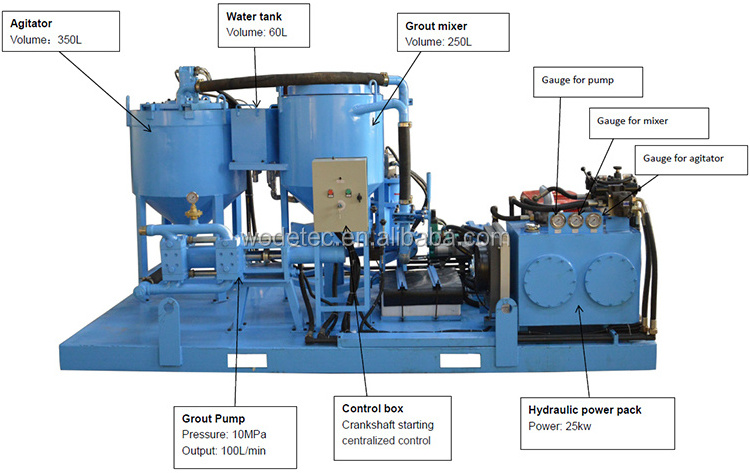

WGP250/350/100PI-D cement mixing injection plant

for jet grouting

GGP250/350/100PI-D Grout Station

is a hydraulic driven combination of mixer, agitator and grout pump, it is specially design for continuous cement mixing and grouting in ground/underground engineering. It can fast mix water, cement and additive, then the mixed slurry can be stored into a 300 liters agitator, thus the mixing work can continuously be done.

Structure of

WGP250/350/100PI-D cement mixing injection plant

High speed, high-shear colloidal mixer cause a vortex flow to ensure mix quickly and evenly. Water, cement or bentonite is quickly mixed into a homogeneous slurry. Then the mixed slurry was delivered to the agitator. Grout pump injects from the mixing drum (storage tank). This ensures a continuous mixing and grouting operations. The

cement mixing injection plant

is hydraulic drive with electric motor. Grouting pressure and displacement is adjustable. Compact size and it is easy to operate. It also takes up a small space.

Application

WGP250/350/100PI-D High pressure hydraulic cement mixing injection plant

is mainly used to be made bentonite slurry, cement slurry, etc., in the application highway, railway, hydropower, construction, mining and other ground and underground construction.

Technical Data

|

WGP250/350/100PI-D hydraulic cement mixing injection plant:

|

|

|

||

|

Name

|

|

Data

|

||

|

Type

|

|

WGP250/350/100PI-D

|

||

|

Diesel engine

|

|

25Kw

@2200r/min

|

||

|

Dimension

|

|

3300x1650x1500mm

|

||

|

Weight

|

|

1400Kg

|

||

|

Mixer

|

Volume

|

250L

|

||

|

|

Speed

|

1500rpm

|

||

|

Agitator

|

Volume

|

350L

|

||

|

|

Speed

|

36rpm

|

||

|

Grouting pump

|

Type

|

Hydraulic Two Cylinder Piston Pump

|

||

|

Grouting pump

|

Pump pressure

|

100bar

|

||

|

|

Pump output

|

100L/min

|

||

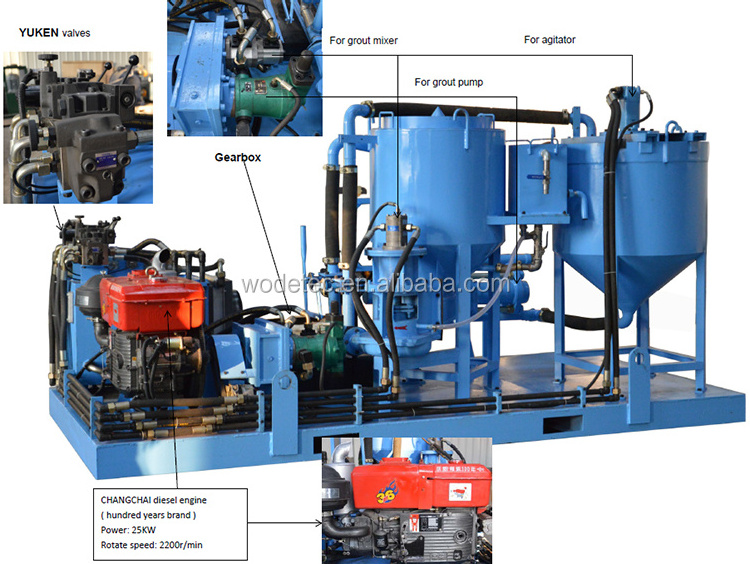

Feature

1. Diesel and full hydraulic driven.

2. PLC and HMI control.

3. Mixer and agitator switch is a squeeze handle that is easy to operate and reliable.

4. Double cylinders piston pump to ensure the continuous slurry flowing (small pulse) and not easily leaking compared with the double acting piston pump.

5. Grouting pressure and output are step-less adjustable.

6. Over hydraulic oil temperature protection.

7. With function of record and display grouting pump reciprocating times by a counter.

8. Solid State Relay.

Product Details

Mixing system

Control box

Yunken valves

Air filter

Piston pump

Details of grout mixing plant

Diesel engine

Gearbox equipment

Recommend Products

Packaging&Shipping

Contact Us

If you have any questions about

cement mixing injection plant

, please contact us and we will provide you with the corresponding product parameters and quotations. We are

cement mixing injection plant

factory, supplier and

manufacturer

, we also can customize according to your requirements.

contact us

for more information

In order to suitable model

cement mixing injection plant

, please let us know the follow questions:

1. How about the flow and pressure of the pump you want, please?

2. How about the water and cement ratio, does any sand in?

3. About the power: electric (voltage and frequency) or diesel?

Hot Searches