- Product Details

- {{item.text}}

Quick Details

-

Drill Diameter:

-

100mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QDZD

-

Voltage:

-

220V/380V/415V

-

Power:

-

3KW

-

Dimension(L*W*H):

-

1500*1000*1200mm

-

Weight (KG):

-

560

-

Product name:

-

Portable Double Ends Mortise And Tenoner Bit Chisel Mortising Machine

-

Working table size:

-

500*230mm

-

Max. mortising length:

-

120mm

-

Max. mortising depth:

-

60mm

-

Spindle speed:

-

9000r/min

-

lifting stroke of working table:

-

80mm

-

Tilting of working table:

-

±25°

-

Motor power:

-

3kw

-

Overall dimension:

-

1500*1000*1200mm

-

MOQ:

-

1 SET

Quick Details

-

Application:

-

woodworking mortising

-

Motor Speed:

-

9000r/min

-

Marketing Type:

-

Hot Product 2022

-

Drill Diameter:

-

100mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QDZD

-

Voltage:

-

220V/380V/415V

-

Power:

-

3KW

-

Dimension(L*W*H):

-

1500*1000*1200mm

-

Weight (KG):

-

560

-

Product name:

-

Portable Double Ends Mortise And Tenoner Bit Chisel Mortising Machine

-

Working table size:

-

500*230mm

-

Max. mortising length:

-

120mm

-

Max. mortising depth:

-

60mm

-

Spindle speed:

-

9000r/min

-

lifting stroke of working table:

-

80mm

-

Tilting of working table:

-

±25°

-

Motor power:

-

3kw

-

Overall dimension:

-

1500*1000*1200mm

-

MOQ:

-

1 SET

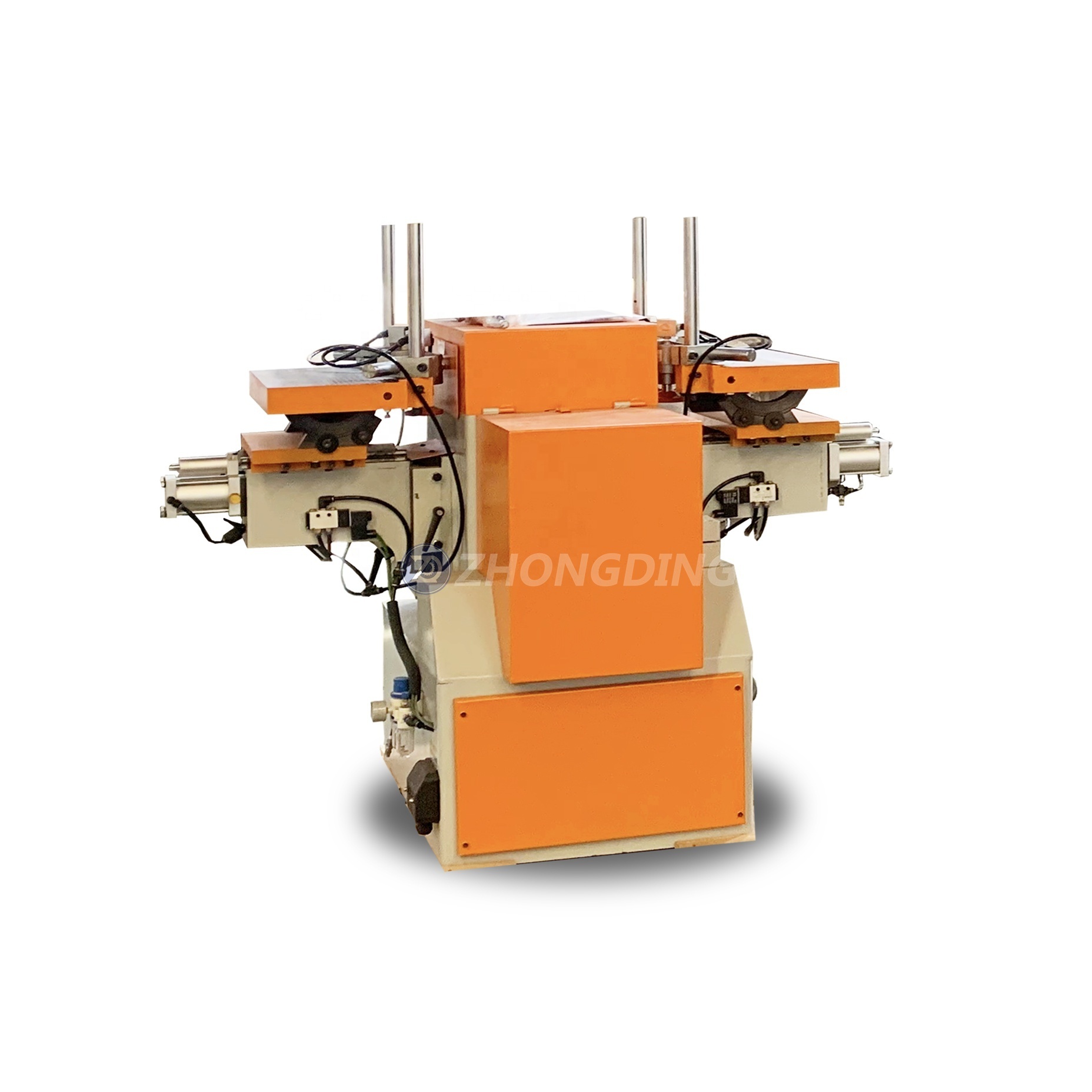

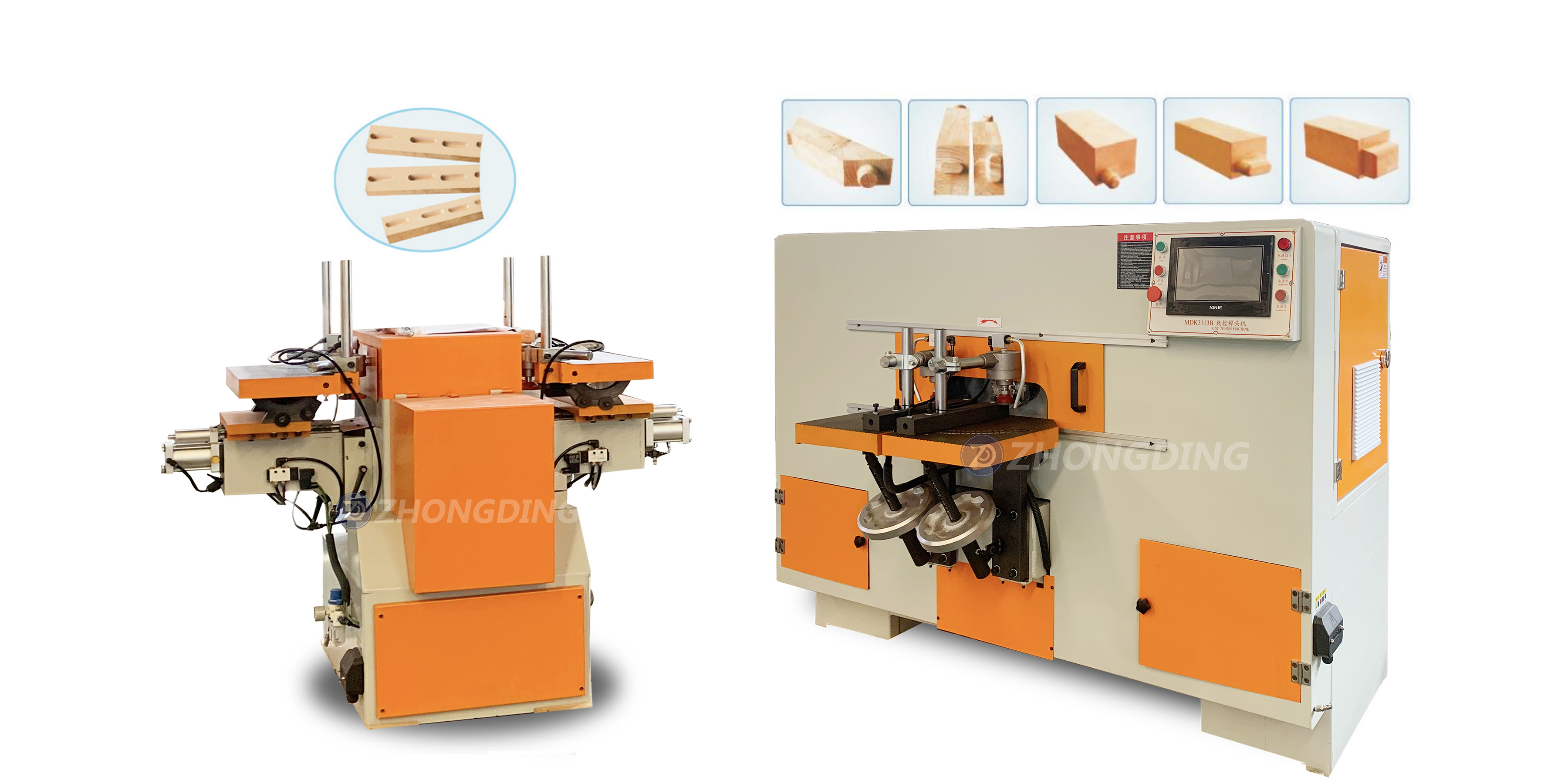

Portable Double Ends Horizontal Wood Slot Cnc Door Lock Hole Mortise And Tenoner Bit Chisel Mortising Machine

Product Description

Specification

|

Product name

|

Mortising machine for Woodworking

|

|

Model

|

MDK3003

|

|

Working table size

|

500*230mm

|

|

Max. mortising length

|

120mm

|

|

Max. mortising depth

|

60mm

|

|

Spindle speed

|

9000r/min

|

|

Lifitng stroke of working table

|

80mm

|

|

Tilting of working table

|

±25°

|

|

Install motor power

|

3kw

|

|

Weight

|

560kg

|

|

Overall dimension

|

1500*1000*1200mm

|

Machine Details

Features:

Double table, high speed spindle, high efficiency.

It is used for tenon and groove processing of doors, tables, chairs and other products.

The width can be adjusted through the digital display, and at the same time, the working surface can be tilted at 30 degrees for tilting and processing of inclined grooves.

The main shaft assembly slides along the precision cylindrical guide rail, and the weighing frequency is high to ensure the processing quality and efficiency.

The double table tops can be processed at the same time on the left and right sides, which improves the efficiency of double work, and the work table can be processed at an inclination angle.

The spindle assembly slides at high speed along the precision guide rail, with high precision and fast movement, and the high-precision spindle is suitable for heavy cutting.

Manual adjustment of the tenon width parameters through the digital display makes it easier to adjust the processing size and the processing is more accurate.

The unique speed regulating structure can regulate the speed of the spindle tenon and groove processing to meet different processing needs and ensure processing quality and efficiency.

1. Thickened workbench

Thickened cast iron workbench with smooth and stable surface.

2. Stable operation

The pressed parts do not damage the material, and the product processing is smooth and smooth.

3. Air control

Pneumatic control, stable processing, high technology, high processing precision.

4. Table adjustment

The angle of the table is adjustable to complete the processing at various angles.

Packing & Delivery

Hot Searches